Manufacturing site of Logistics/warehousing operations of Thorough efficiency!

Inventory and picking operations

Labor saving and efficiency can

On-site document electronic system

- The implementation cost is less than one-fifth of that of a handheld terminal!

- Accurate data entry is achieved for receiving, shipping, and inventory work, and errors are dramatically reduced!

- Make picking super efficient with batch and continuous barcode scanning!

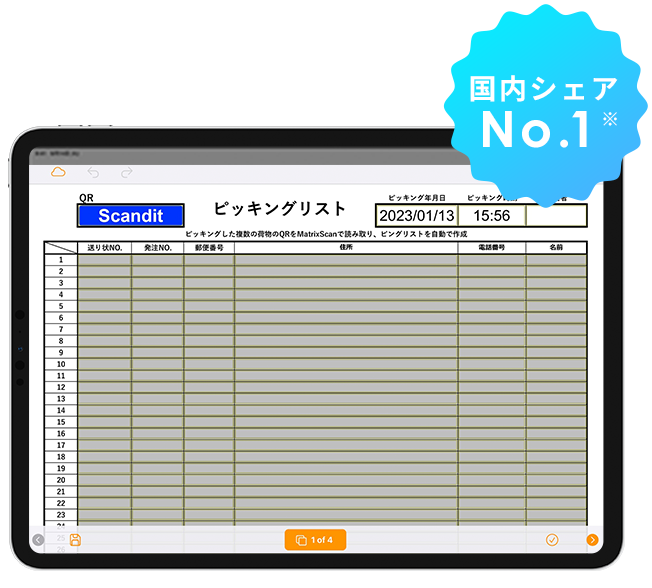

Fuji Chimera Research Institute, Inc. Published on August 8, 2024

Industry-specific IT Investment/Digital Solutions Market 2024 Edition

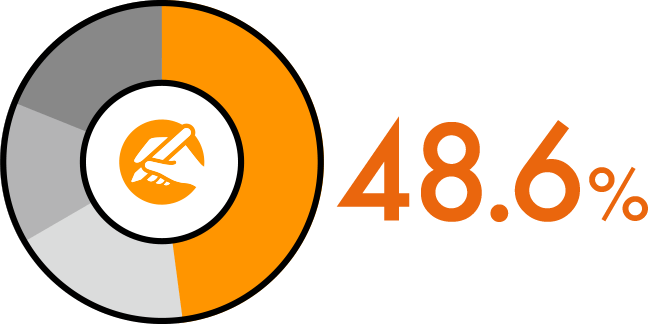

I-2 Paperless on-site document solutions market share: 48.6%

(Vendor share and volume for FY2023)

Logistics and warehousing operations in the manufacturing industry... Do you have any of these concerns?

Incoming and outgoing

Inventory Management

Inventory work

picking

Raw material input

- When checking, each item is visually checked, so there is no need to add it to the management table.There are many errors, omissions, and variations in format

- Transcription of data from paper management sheets to other systems is a lot of work

- There are many picking and shipping errors, and we receive complaints from delivery destinations.

- The high cost of handheld terminals and systems has hindered their adoption

- The process takes time because barcodes are read one by one.

The problem

i-Reporter has the solution!

Inventory and picking operations

Labor saving and efficiency improvement

On-site document electronic system

Download now for free!

Understand the logistics industry in detail!

Bye-bye 3-piece set for misdelivery

Understand logistics errors and their causes, and learn how to prevent themYou can download the three documents as a set.

| In this documentWhat you will learn |

|

|---|

-

In warehouse and logistics operationsWhat mistakes occur?

-

i-Repo ScanReduce delivery errors with AR!

-

Handheld terminal "installation cost"

Concerns about "development costs"

What's great about i-Reporter

Improve work efficiency with batch and continuous barcode reading!

The work of visually checking each item,

Ultra-fast barcode reading function

Multiple barcodes can be displayed on the screen in succession and read simultaneously and continuously.

Even if there are a large number of barcodes containing multiple different types, it is possible to read only the barcodes specified in advance.

Regular inventory and picking tasks can also be dramatically sped up.

What's great about i-Reporter

Barcodes that do not match the conditions

Discrimination to prevent work mistakes

If you prepare the list in advance,

The scanning function allows for instant identification!

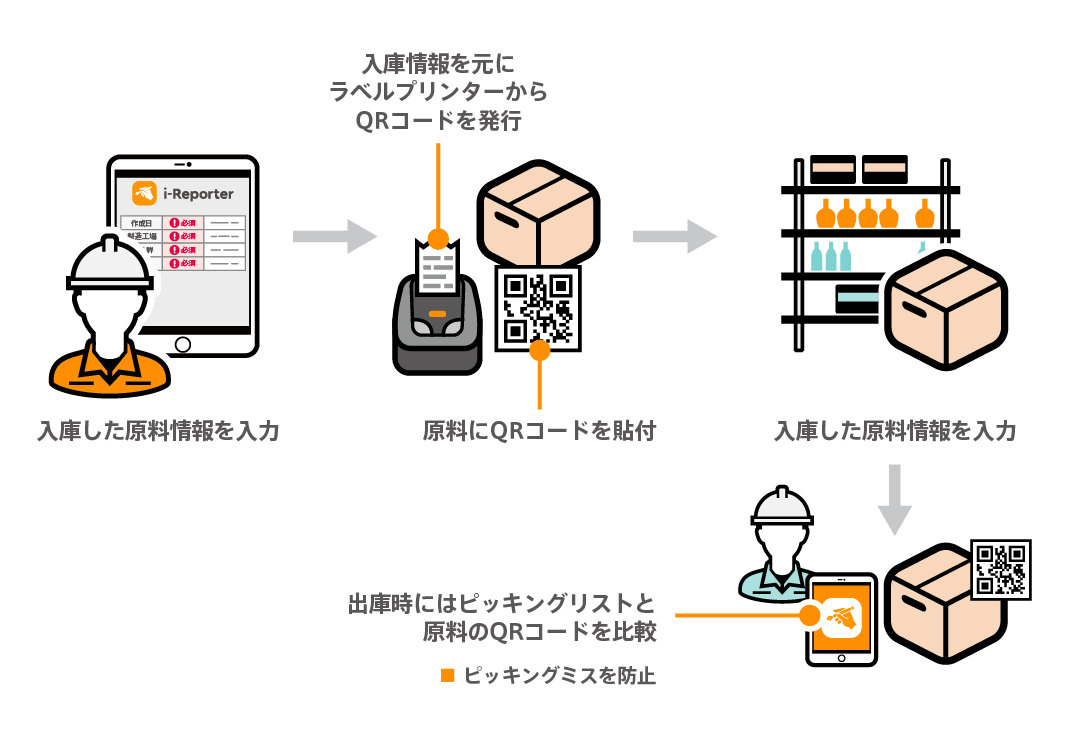

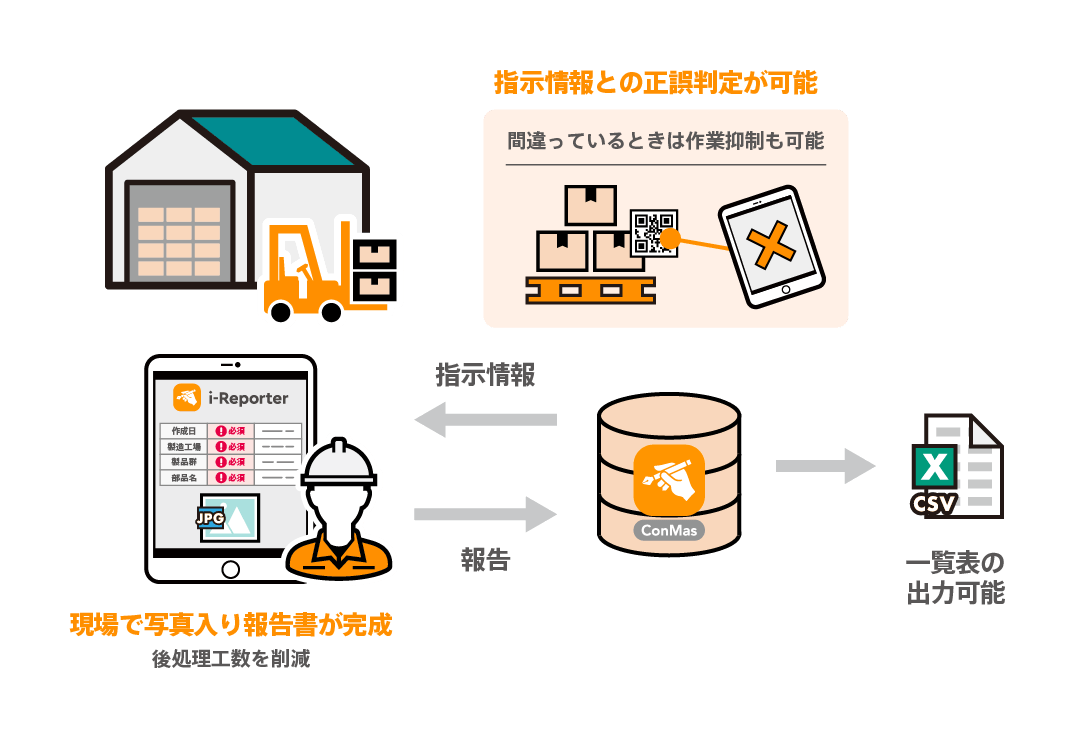

By preparing a list of planned readings in advance, it is possible to determine whether the planned readings and actual results are correct.

The barcode scanning function displays non-existent barcodes in red and beeps to alert you, preventing misreading. This allows for intuitive, error-free, and efficient work.

*Note: i-Repo Scan is required.

What's great about i-Reporter

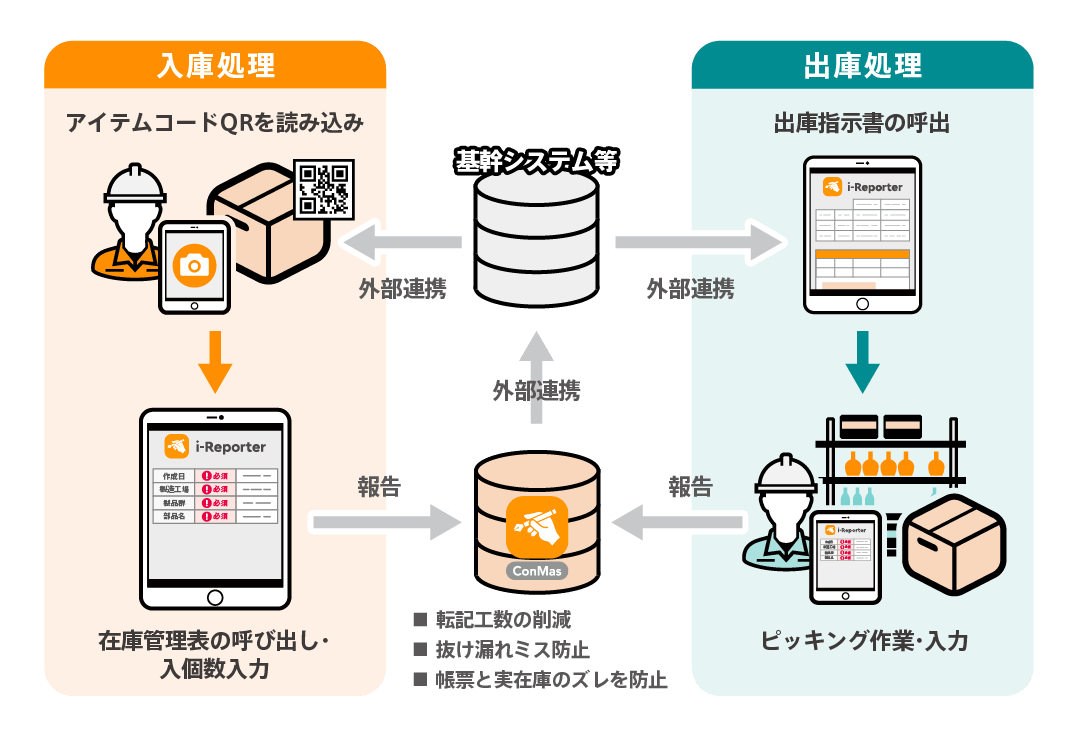

By linking data with the host system,

No transcription required!

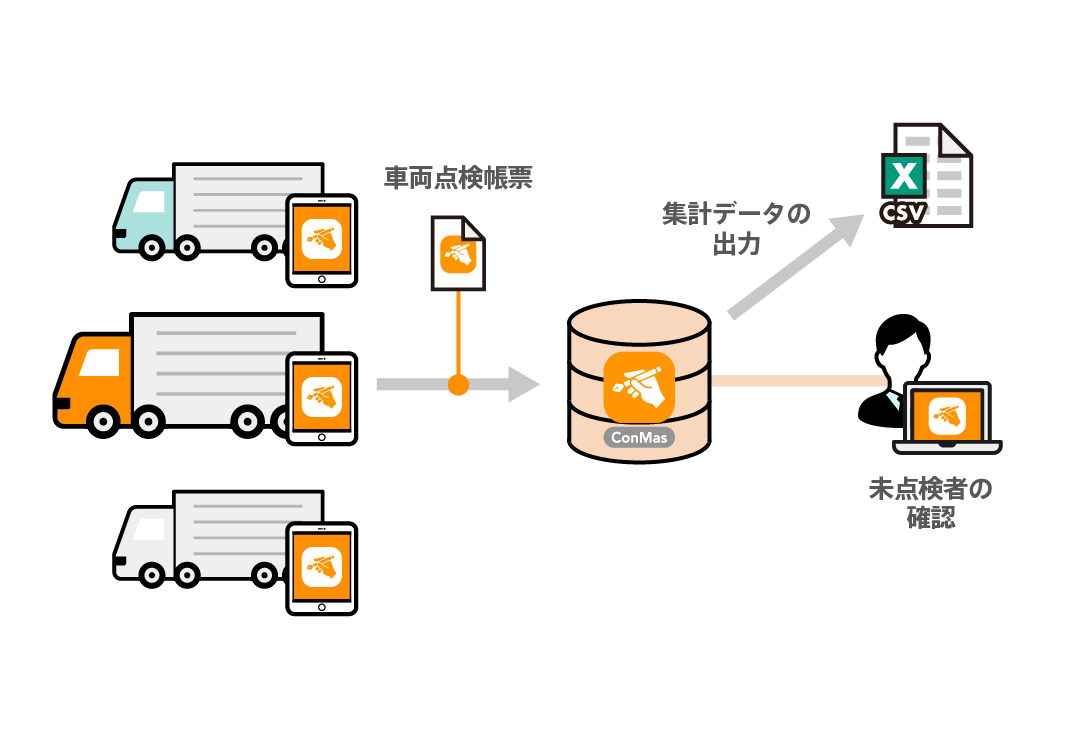

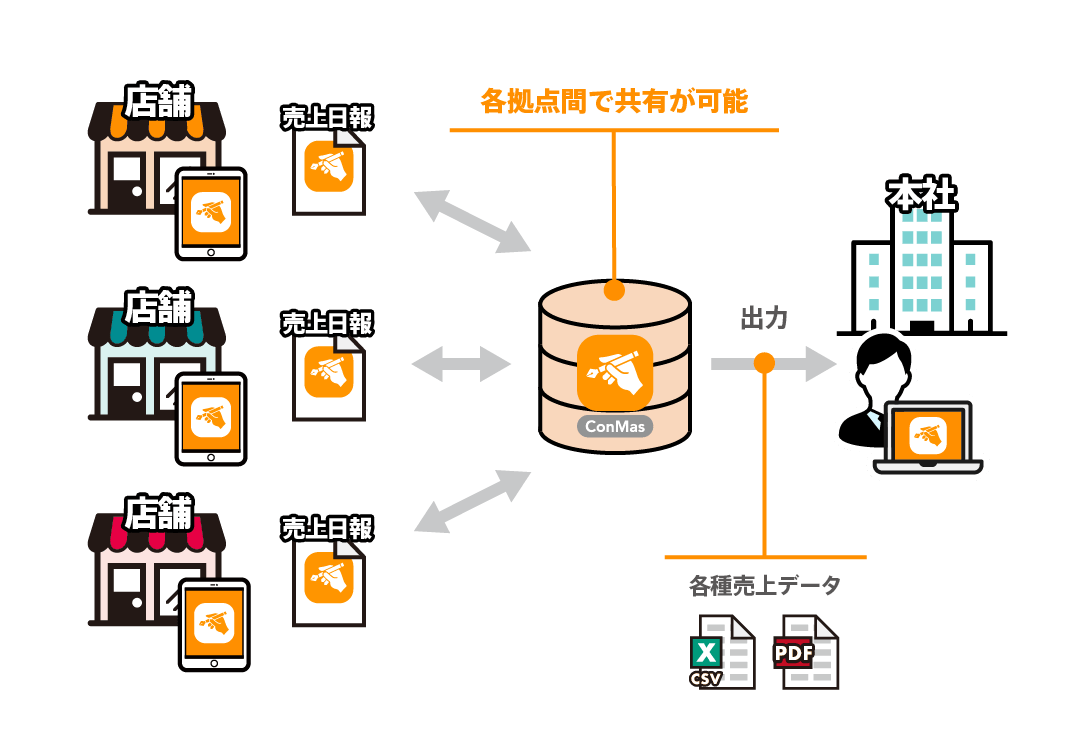

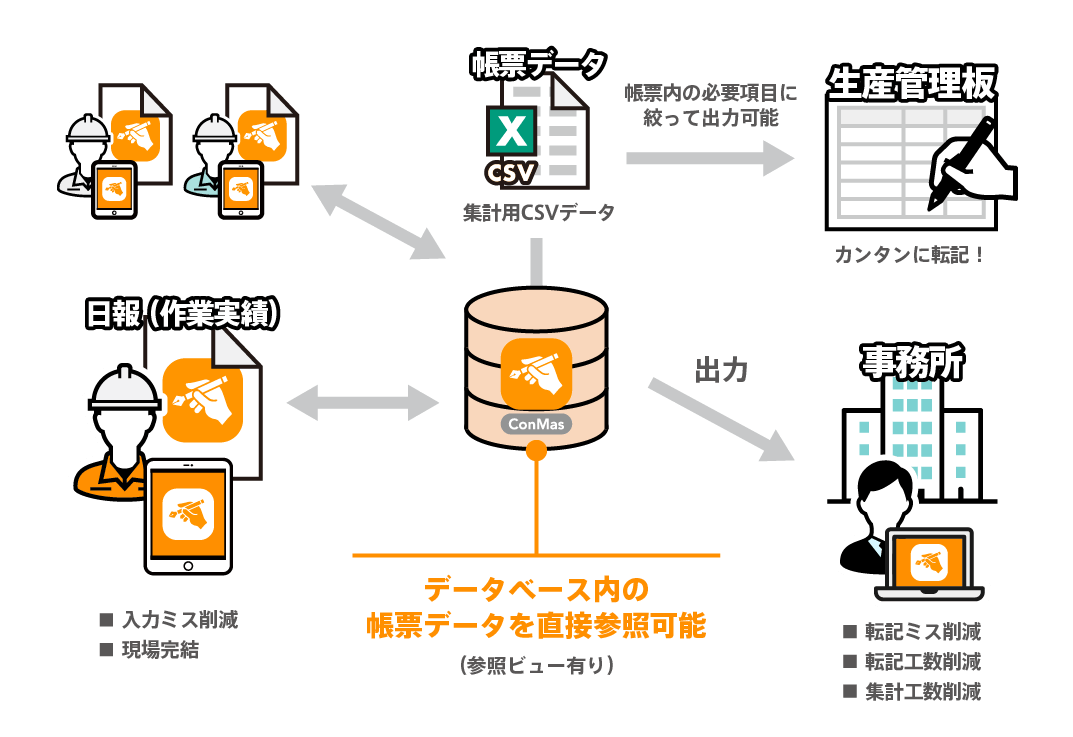

The data is automatically reflected in the higher-level system.

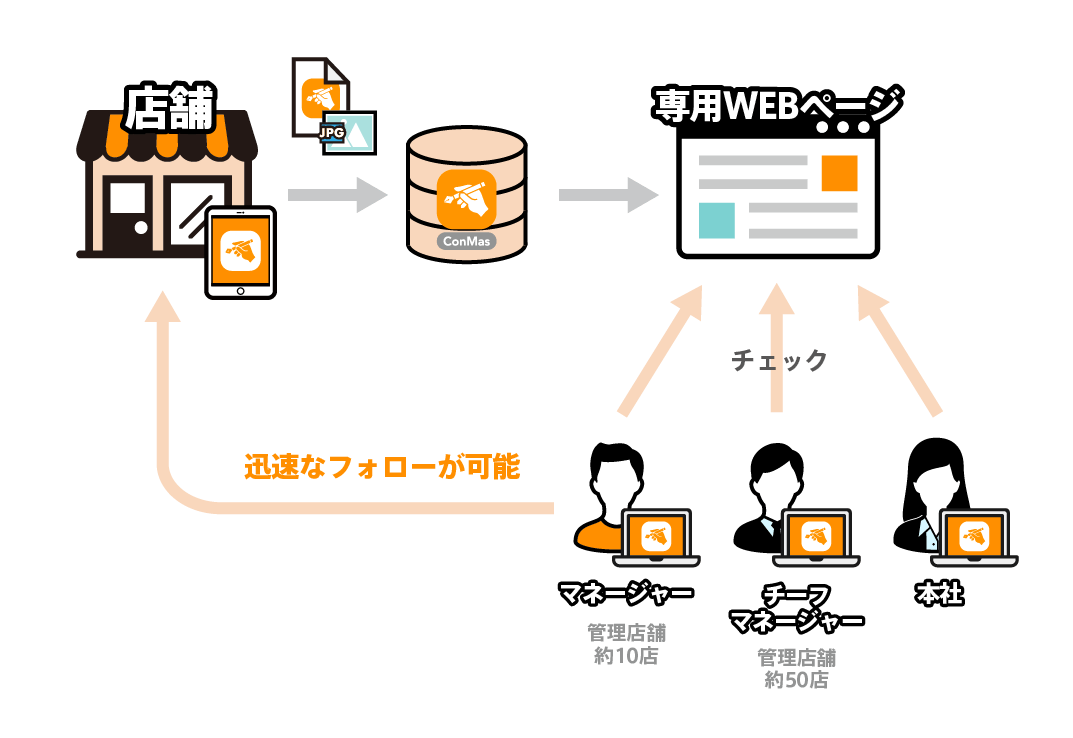

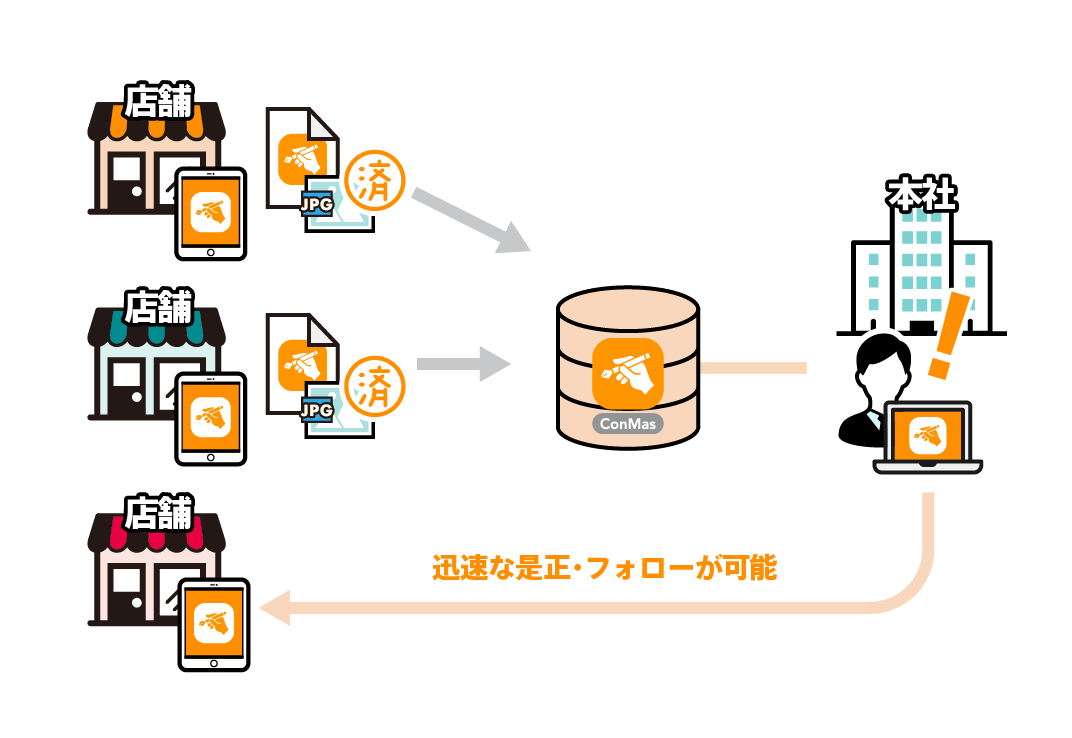

Grasp the situation on-site in real time

By simply entering work progress and results into a tablet, the data can be automatically reflected in other systems. This eliminates the need for unnecessary transcription work and allows you to grasp the situation in real time.

This eliminates transcription errors and reduces discrepancies between logical and actual inventory.

*Note: Collaborative development with other systems is required.

What's great about i-Reporter

The input screen can be operated by anyone no-code

Easy to create!

Feedback from the field can be reflected immediately in reports, improving the speed of improvement.

Report layouts created in Excel can be imported and reflected in the system as is. Familiar on-site reports can be systemized as is, so they can be used on-site without any instruction on input methods. Report maintenance can also be done in-house, significantly reducing the cost and time required for changes.

What's great about i-Reporter

No need for expensive dedicated handheld terminals!

Conventional systems using handheld terminals and

In comparison, the implementation cost is less than one-fifth!

i-Reporter is an app that runs on iPad, iPhone, and Windows (*note), so there is no need for dedicated devices such as handheld terminals. Because it allows for the creation of no-code barcode reading apps and system integration development, it can reduce the cost of introducing a system using a conventional handheld terminal to less than one-fifth of what it used to be.

*Note: Barcodes cannot be read using the camera on Windows tablets.

Over 4,500 companies have adopted it!

Paperless app

No.1 share

Inventory and picking operations

Labor saving and efficiency improvement

On-site document electronic system

Please feel free to contact us first!

Key Features

-

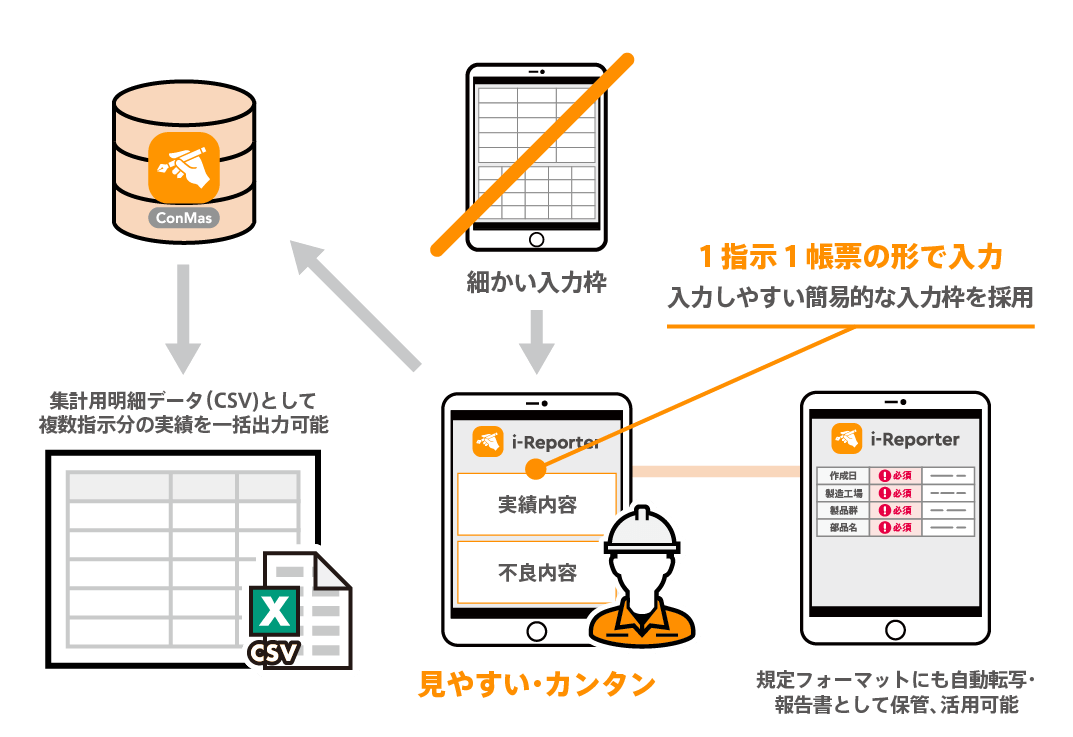

Creating/entering reports

We have thoroughly pursued creating reports that are easy to read and understand, allowing field workers to input data easily and without making mistakes.

Learn more -

Form design

(Create a template)Convert your familiar Excel forms into electronic forms. After you start using the system, you can easily change the form layout or add items in Excel.

Learn more -

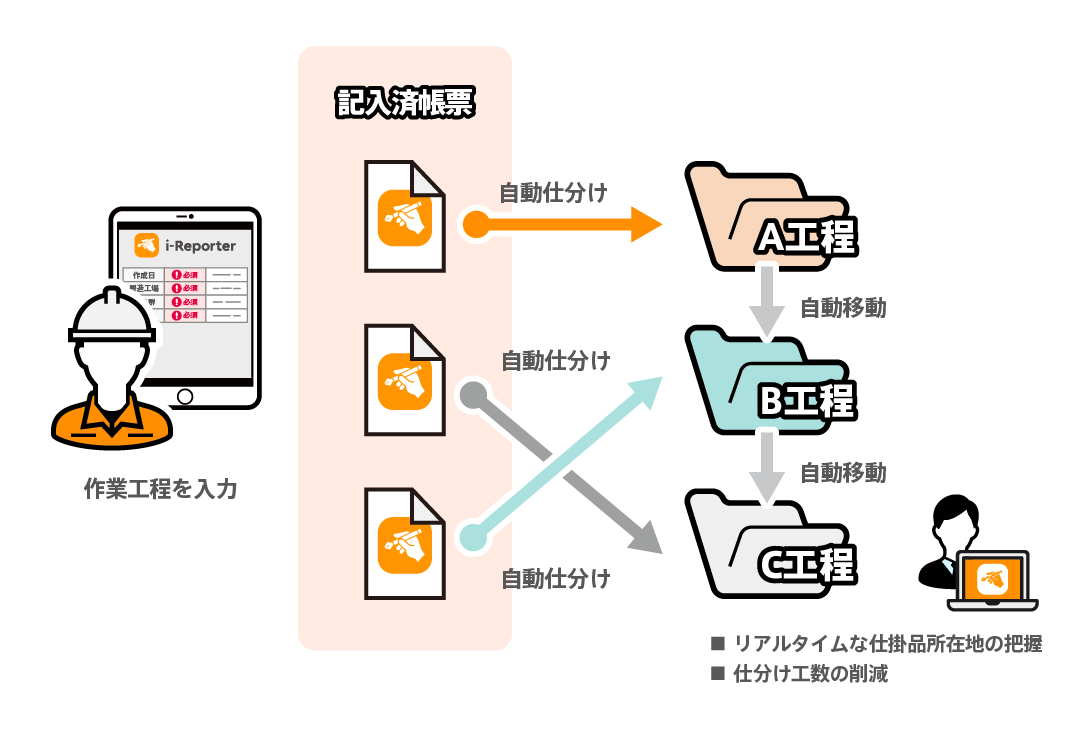

Form Management

The data of the created reports is centrally managed by the system, and reports can be viewed, edited, and printed from the web management screen.

User authority management and security measures are also in place.Learn more -

System Integration

It has a wide range of functions for linking data with external systems. It automates processes such as tabulation, reporting, and analysis after inputting forms, significantly improving work efficiency.

Learn more

Features especially recommended for logistics and warehouse operations in the manufacturing industry

\ Learn from the video / i-Reporter barcode scanning

Batch & Continuous

With barcode scanning

Quantity counting function

It is possible to count the quantity of the same code by reading it in bulk or continuously, which greatly improves the efficiency of inventory counts and checks during inbound and outbound shipments. The barcode content and counted quantity are displayed on the screen, allowing workers to intuitively check the content and quantity of the barcodes they have read. The read content can be added up in a ledger.

Abundant input assistance functions

A wide range of digital inputs are available, including text, numbers, options, dates, input from master data, and voice input.

By utilizing threshold judgments and Mandatory input settings, you can not only reduce work errors and omissions, but also speed up input and improve work efficiency.

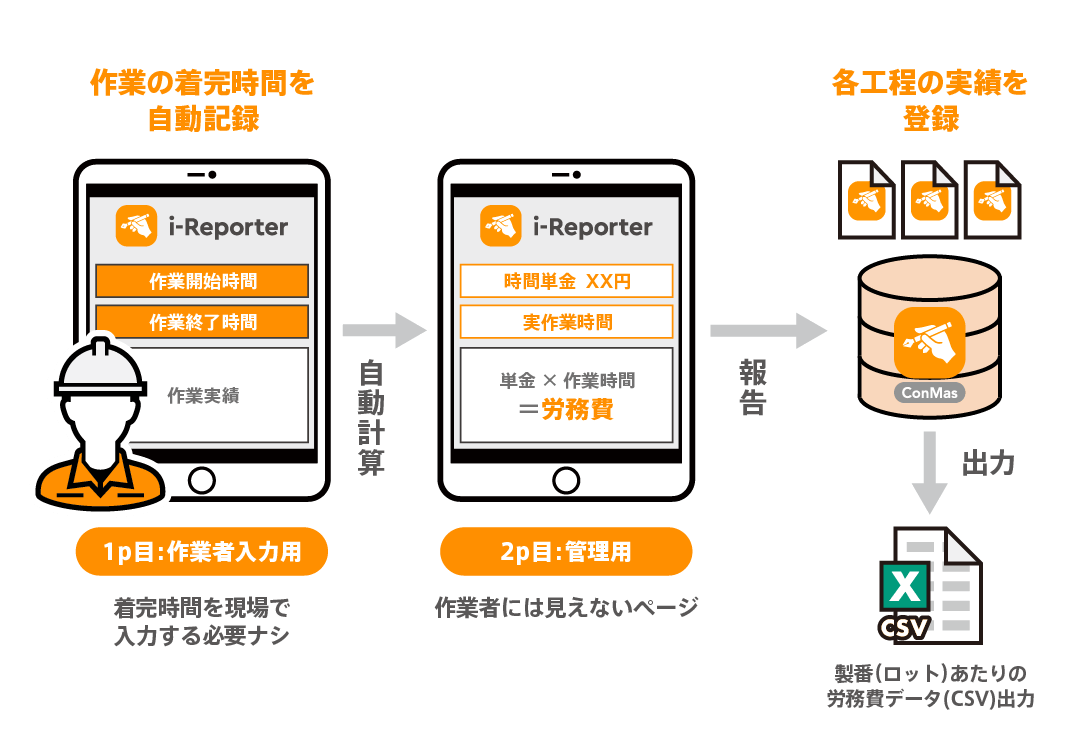

automatic calculation

i-Reporter allows you to set calculation formulas such as arithmetic operations, and the system will automatically calculate the results.

There is no need to do mental calculations or use a calculator, so calculation errors are eliminated.

Peripheral device connectivity

(Microphones, measuring equipment, NFC, RFID, Bluetooth)

It can be connected to a wide range of peripheral devices, including microphones for voice input, barcode readers, and digital measuring devices, allowing for a wide variety of input methods that were not possible with paper.

Examples of problem solving by industry

Download it now for free!

Warehouse and logistics personnel

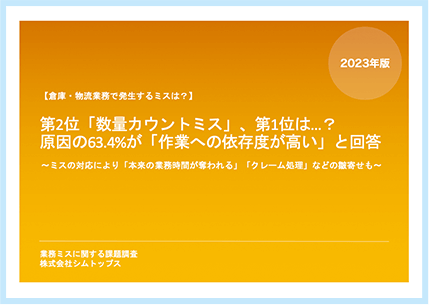

70% of people worry about mistakes What is it?

Frequent mistakes in warehouse and logistics operations, their causes, and activities to resolve themYou can download a document summarizing the survey results.

What you'll learn from this document

- Ranking of the most common mistakes made in warehouse and logistics operations

- Ranking of activities aimed at solving the 2024 problem

- Ranking of causes of errors in warehouse and logistics operations

Feedback from customers on the ground

After introducing i-Reporter,

Reduce shipping management work by 90 %

Inventory management tasks that were previously done on paper can now be easily entered on an iPad.

Furthermore, i-Reporter synchronizes inventory numbers with the core system and production management system, eliminating the need for manual transcription work that had previously been done on each system.

Previously, managing inventory shipments took about 840 minutes per month. However, by adopting i-Reporter, we no longer had to write by hand or calculate inventory numbers; instead, we could simply tap on the screen to complete the task. It feels like we've reduced our work time by about 90%.

Received from ITreview

Customer Reviews

i-Reporter's track record

Over 4,500 companies have adopted it!

No.1 share in paperless apps

-

Site reports

Paperless Solutions

Domestic market volume

Achieved the top market share of 48.6%! *1

In the manufacturing and machinery industry

Evaluation by employees of small and medium-sized enterprises

function Satisfaction with *2

Large corporations

Evaluation by people working in information systems

Ease of implementation Satisfaction with *3

*1 Source: Fuji Chimera Research Institute, Inc. published on August 8, 2024, IT Investment/Digital Solutions Market by Industry, 2024 Edition I-2, On-site Paperless Document Solutions Market Share: 48.6% (Vendor Share and Volume in FY2023)

*2 Data details: As of July 13, 2023. Calculated from the percentage of ITreview reviewers who gave a rating of 4 out of 5 for satisfaction with the functionality. Job type: Manufacturing/machinery, Company size: Small and medium-sized enterprises. Number of respondents: 12.

*3 Data details: As of July 13, 2023. Calculated from the percentage of ITreview reviewers who gave the ease of implementation a score of 4 out of 5. Job type: Manufacturing/machinery, Company size: Small and medium-sized enterprises. Number of respondents: 12.

-

Implementation track record

Number of contracted users

Over 220,000 people!

As of May 2025

-

ConMas i-Reporter

Thanks to you

Adopted by 4,346 companies!

As of May 2025

Flow of implementation

You can consider introducing the product after seeing an explanation and demo of the actual product.We provide thorough support from specific consultations at the consideration stage to implementation and operation support.Please feel free to contact us.

-

Request information

-

Product DescriptionSeminar

-

Operation training session &

Free Trial -

Contract

-

Service launchsupport

The survey results are available to download for free!

Digital Inventory Management

In business

Challenges and Solutions What is it?

Dissatisfaction and troubles regarding inventory management and handheld terminal useYou can download the survey results.

Examples of survey results that can be seen in this document

- Inventory management method ranking

- Frustration and problems felt when performing inventory management tasks

- Frustration and issues when using handheld terminals

Frequently asked questions

システムの提供形態は何がありますか?

システムの提供形態は何がありますか?

We can provide either cloud services or on-premise services. Please choose the option that best suits your needs.

For more information, please contact your local distributor or CIMTOPS.

導入前にトライアルすることは可能ですか?

導入前にトライアルすることは可能ですか?

All features are available free of charge for up to 100 users for two months. The trial can be run on cloud or on-premise. For details, please visit the i-Reporter free trial page.

操作講習会などの教育はありますか?

操作講習会などの教育はありますか?

We are preparing free in-person training sessions (Tokyo, Kariya, Kyoto) and online training sessions for customers who are considering introducing our products or who have already purchased them. Please contact CIMTOPS or your local distributor for details.

自社業務システムや各種クラウドサービスとの連携は可能ですか?

自社業務システムや各種クラウドサービスとの連携は可能ですか?

You can use the API for external system integration and ConMas Gateway to integrate with business systems and various cloud services. For details, please contact CIMTOPS or our agents.

Company Profile

CIMTOPS Corporation. provides production management schedulers, process control systems, and on-site report systems.We are a domestic package manufacturer with a strong track record of software that supports the digital transformation of the manufacturing industry.

-

For individual order production

Production scheduler/process control system

-

Bill of Process (BOP) Tool

- Company name

- CIMTOPS Corporation.

(English notation: CIMTOPS Corporation.)

- Establishment

- October 1, 1991

- President and CEO

- Takashi Mizuno

- main office

-

〒141-0021

東京都品川区上大崎2-25-2

新目黒東急ビル10階

TEL:03-5721-4610

FAX:03-3491-4610

- Location

- Chubu Area Office (Kariya)

Kansai Area Office (Kyoto)

- Abroad

- Xinmu Tuosi (Shanghai) Information Technology Co., Ltd.

CIMTOPS SG LAB Pte. Ltd.

Implementing company

Over 4,500 companies have adopted it!

Paperless app

No.1 share

Inventory and picking operations

Labor saving and efficiency improvement

On-site document electronic system