Quality inspection and inspection work of

Increase efficiency

On-site document electronic system

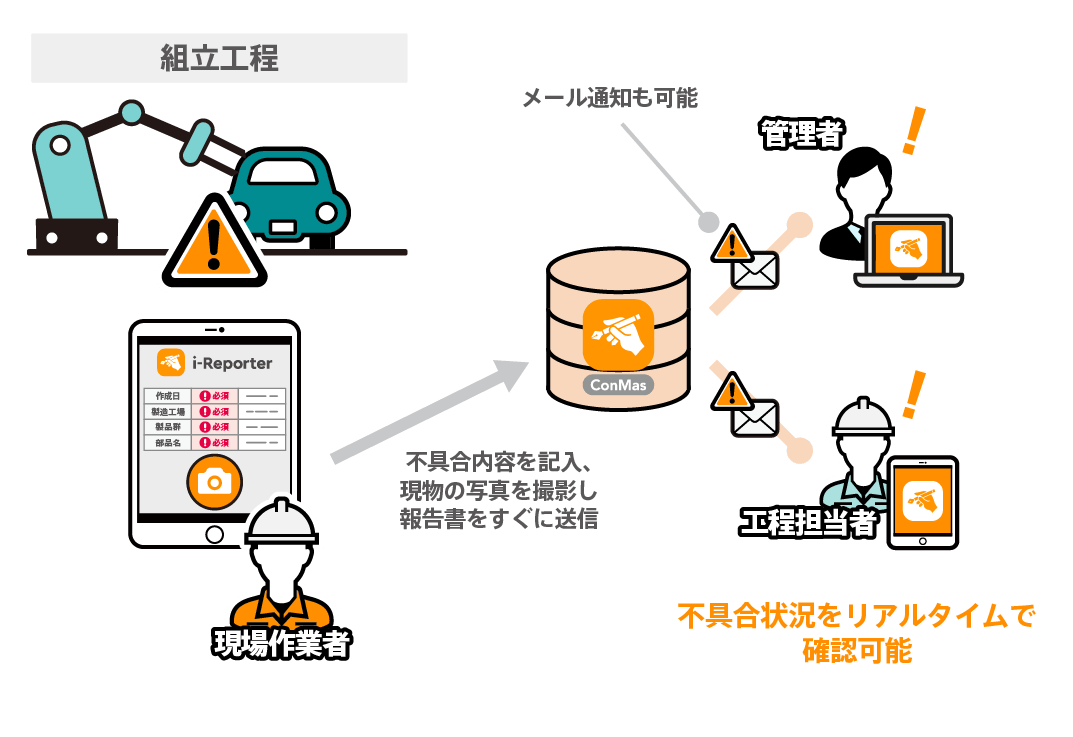

- Abnormalities and defects can be detected immediately, enabling prompt action

- Accumulation of inspection and testing data and real-time visualization

- Easy access to necessary data. No need to search paper forms.

Fuji Chimera Research Institute, Inc. Published on August 8, 2024

Industry-specific IT Investment/Digital Solutions Market 2024 Edition

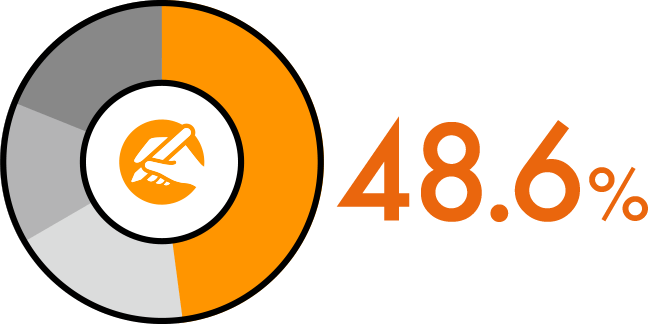

I-2 Paperless on-site document solutions market share: 48.6%

(Vendor share and volume for FY2023)

For quality inspection and inspection work in the manufacturing industry

Do you have any of these concerns?

Acceptance inspection

Raw material inspection and material inspection

In-process inspection

Appearance inspection Foreign matter inspection Filling amount inspection Functionality confirmation inspection

Final Inspection

Visual inspection Functional inspection Durability inspection Assembly inspection- There are many omissions and confirmation errors in quality inspections.

- Even if an abnormal value is detected, the person in charge does not notice it

- Even if a mistake is discovered, it takes time to share the information on-site.

- There are no measures in place to prevent tampering with reports after they have been filled out.

- It is difficult to check whether there are any omissions in the report content, and approval work is time-consuming.

- Distributing, tabulating, analyzing, and managing paper reports during quality inspections is a hassle.

The problem

i-Reporter has the solution!

Over 4,500 companies have adopted it!

Paperless app

No.1 share

Manufacturing

Streamlining quality inspection and inspection work

On-site document electronic system

Download now for free!

Promoting visualization of the workplace

3-piece set

You can learn about the barriers and success stories for promoting "visualization" on-site.You can download the three documents as a set.

| In this documentWhat you will learn |

|

|---|

-

Field reportsWhat is the purpose of digitalization?

-

In the manufacturing industrySurvey on "Factory Visualization"

-

To introduce i-Reporter,Why was there no resistance on the ground?

What's great about i-Reporter

Reduce errors and personal dependency in quality inspections and checks! Efficient report creation possible with correct procedures

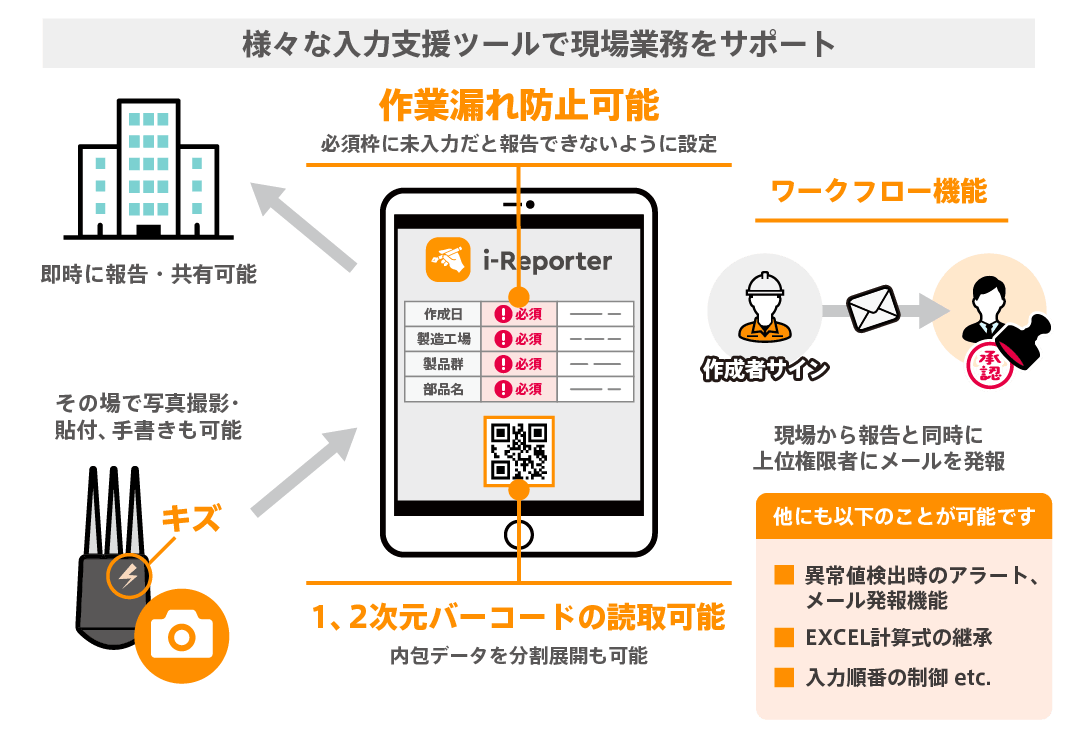

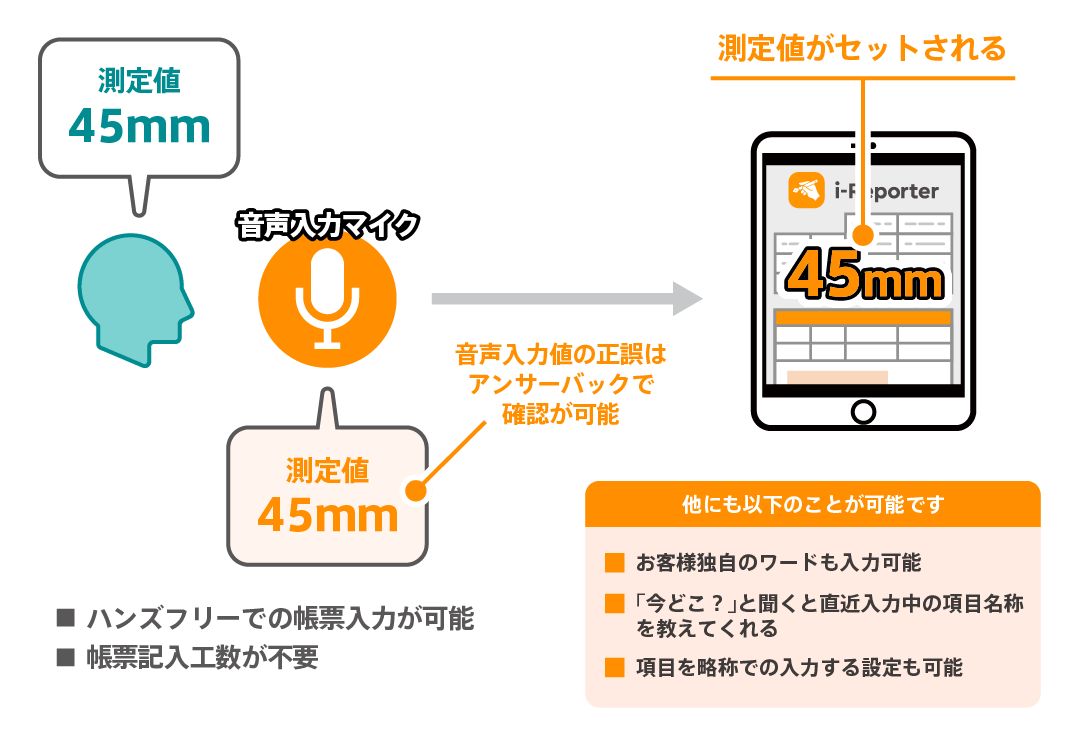

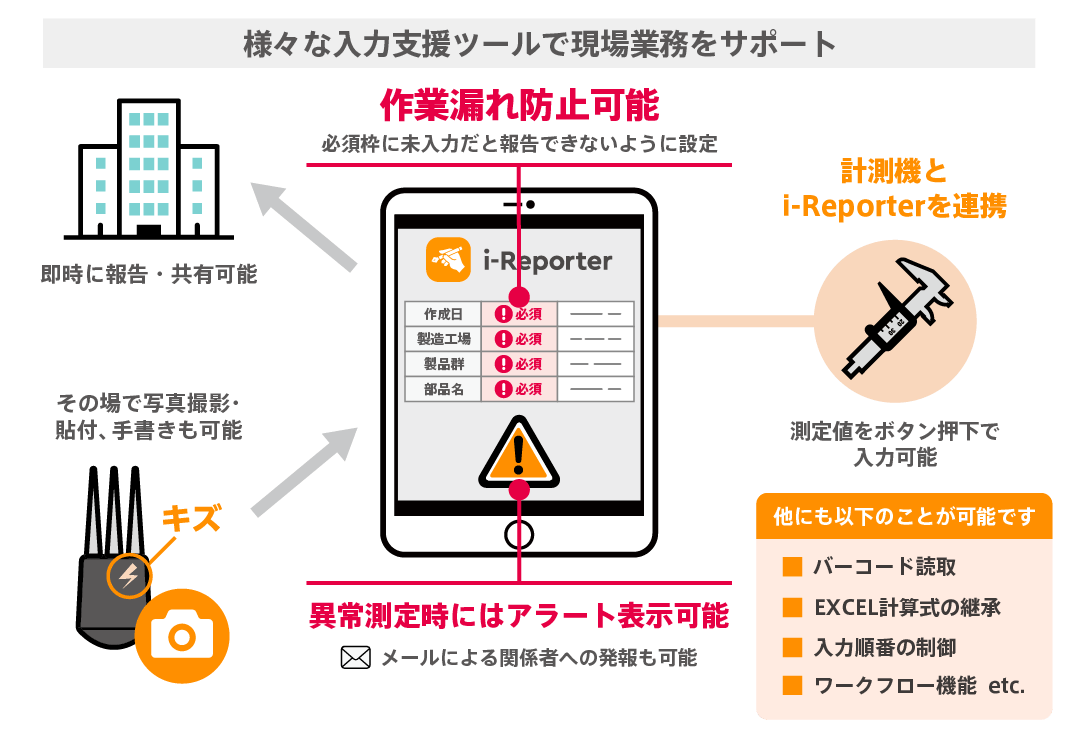

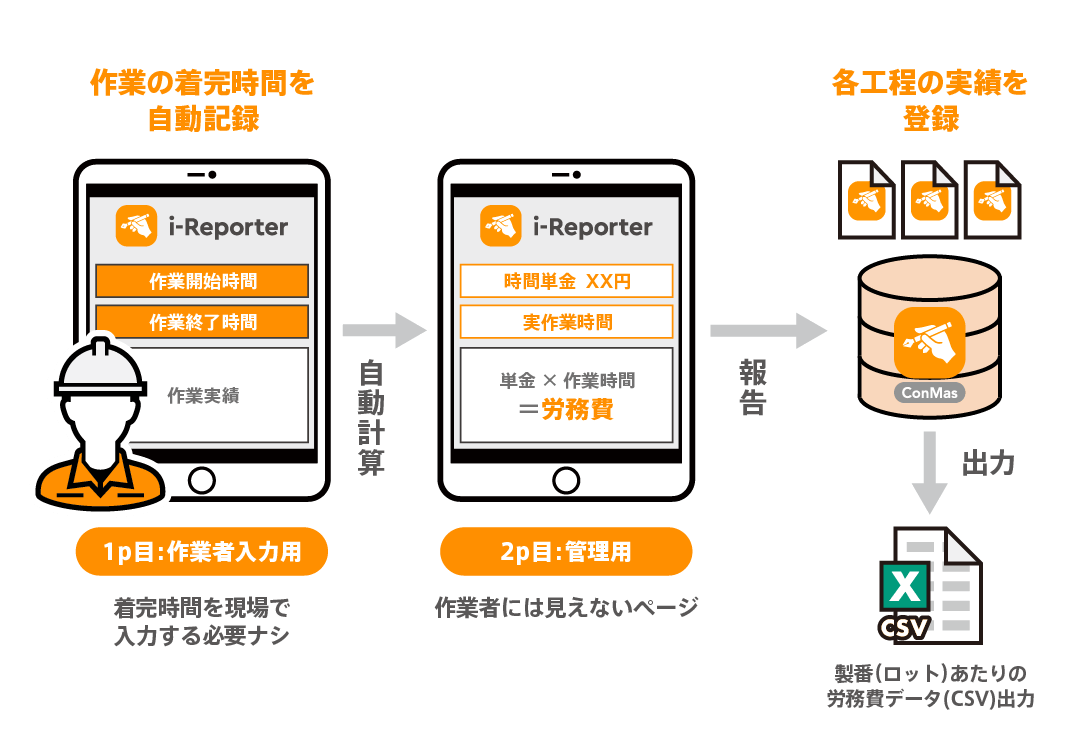

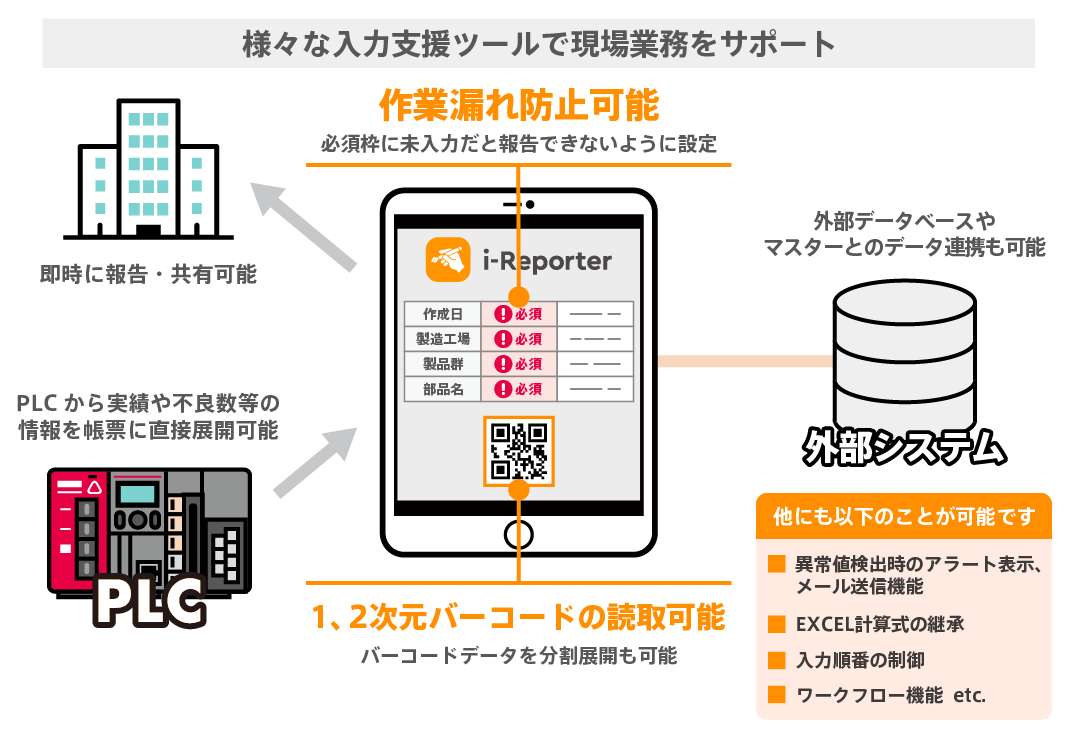

Input assistance functions that make it easy for field workers to input dataThe order of filling out data can be implemented into your company's existing forms.By using mandatory settings and input rule settings, you can significantly reduce errors and omissions.

By setting the input items and order, you can prevent "batch writing" and "deviation from procedures" that are common with paper forms. You can record in accordance with quality control standards and standardize recording methods. There are also a variety of input assistance functions, such as automatic input of units, and you can also record using barcodes.

What's great about i-Reporter

Improve the quality of quality inspections and checks,

It also leads to increased customer trust.

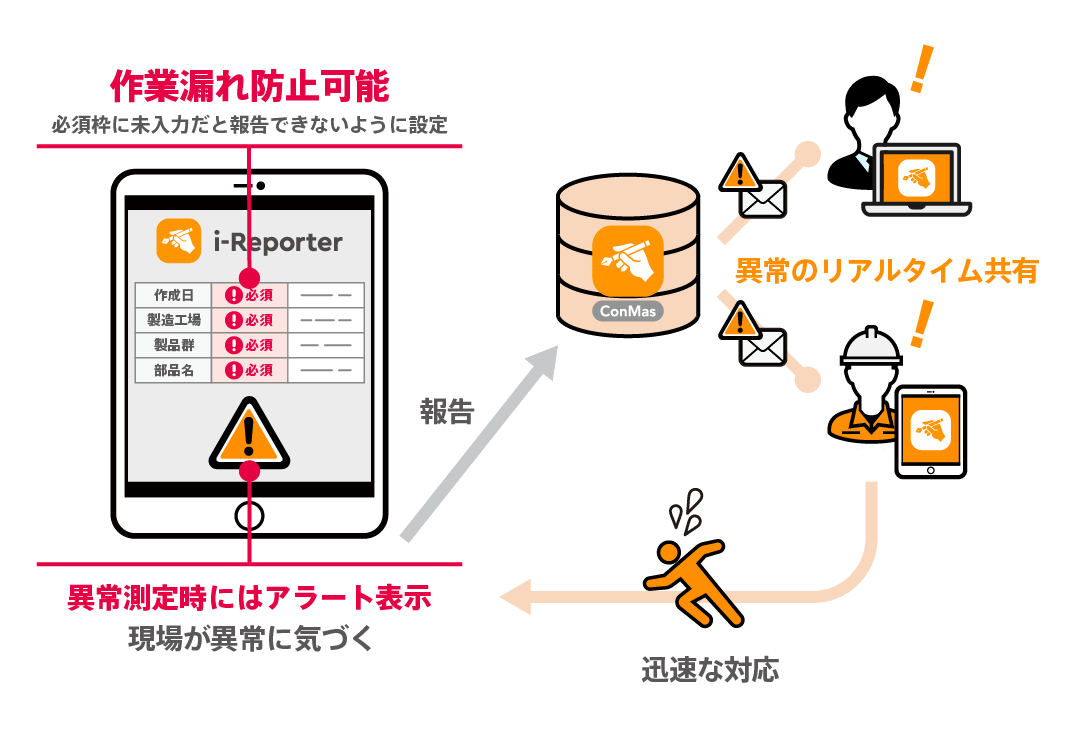

Values outside the allowable range can be immediately determined.Alerts and notifications can also be displayed based on the results of the assessment.

It is possible to set tolerances according to the inspection method and target. An alert can be displayed if the tolerance is exceeded. In addition to alerts, the background color and text color of the input frame can be changed, allowing workers to intuitively notice mistakes. Furthermore, input branching according to the judgment result and automatic notification functions allow for swift action after mistakes are discovered.

What's great about i-Reporter

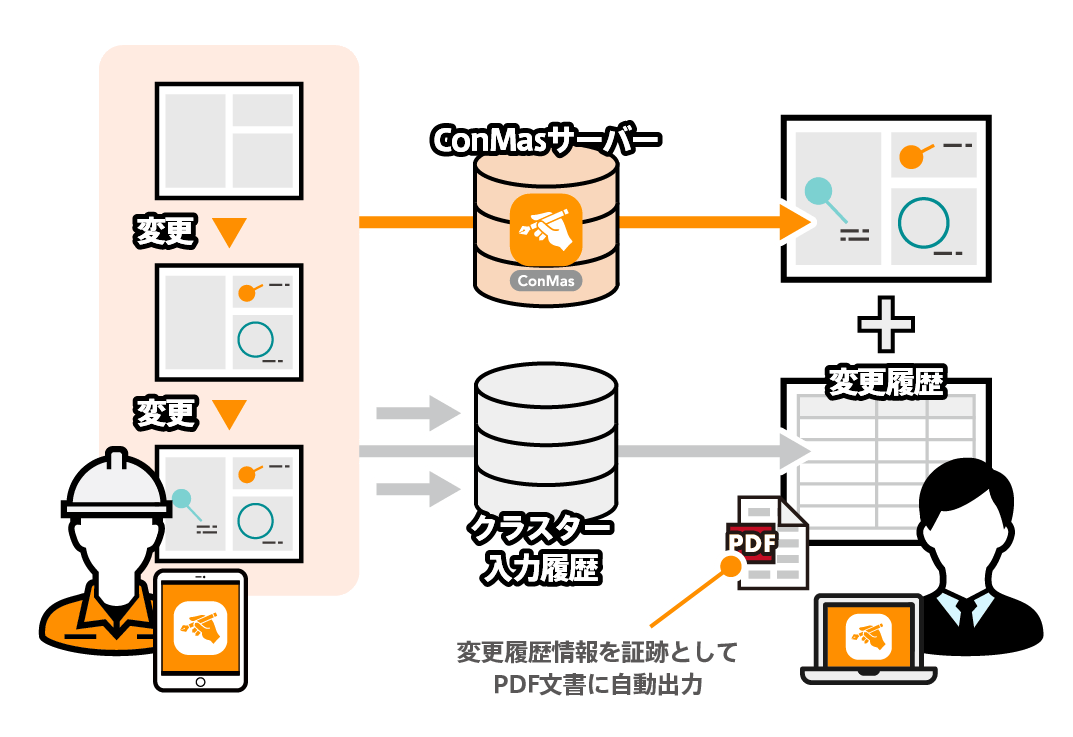

Countermeasures against report falsification

Traceability management is also perfect!

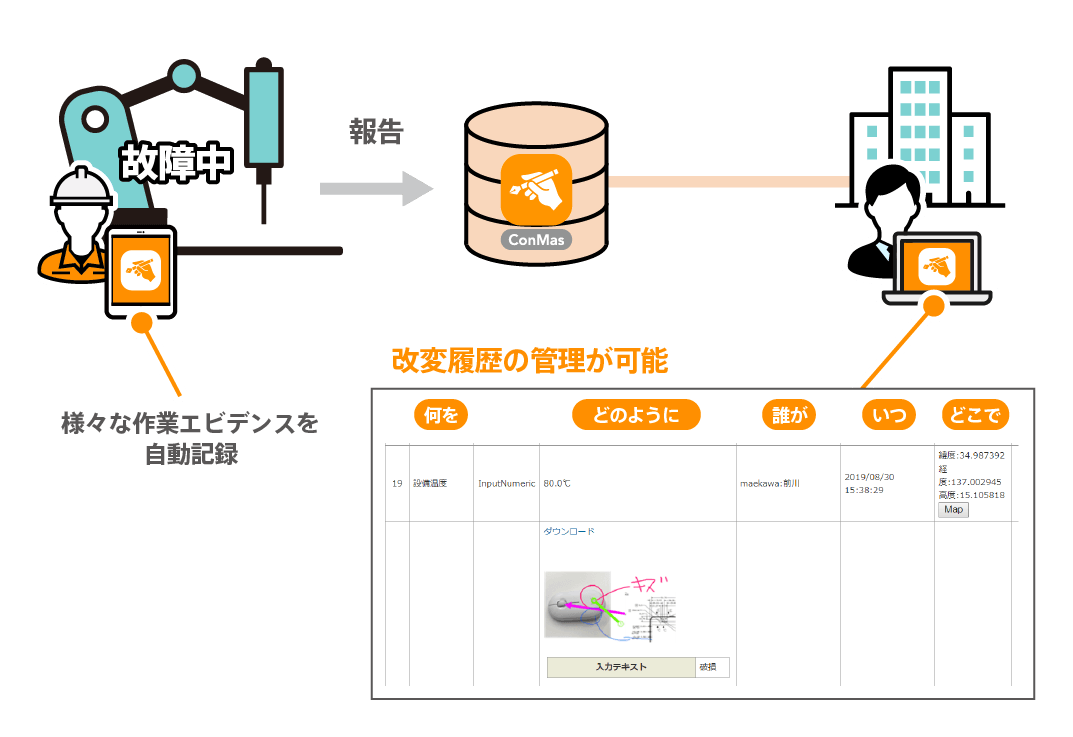

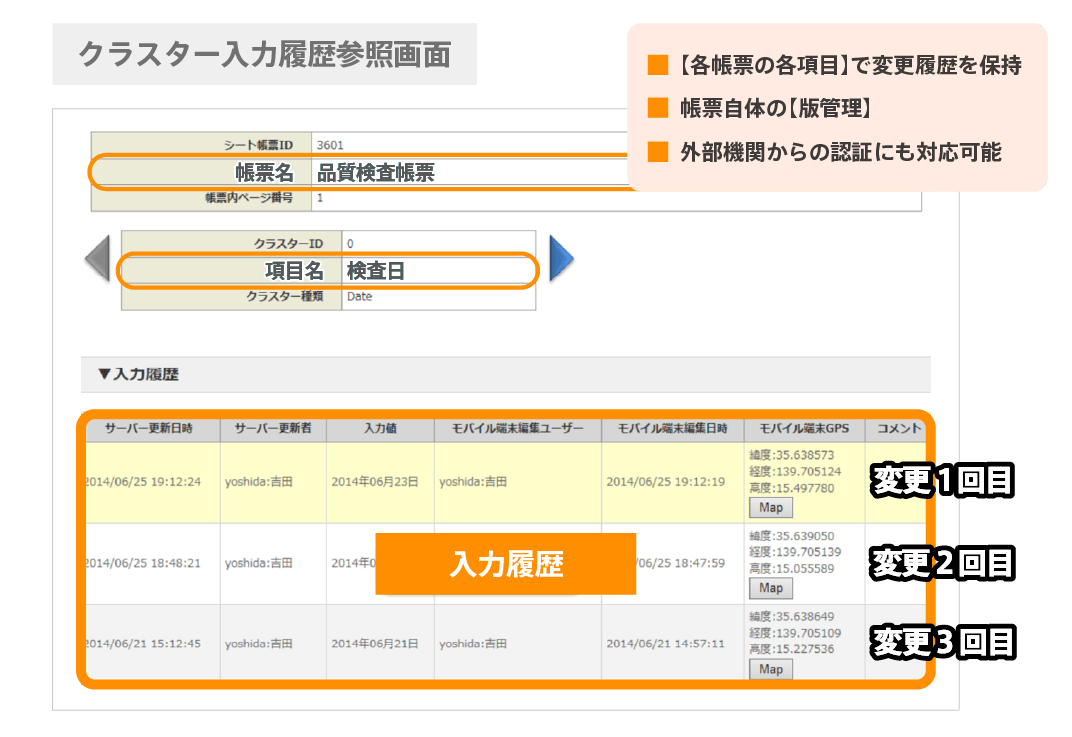

In addition to preventing "unauthorized tampering" through thorough evidence management, version control of records is also possible.

All forms are version-controlled. Every time a document is edited, we carefully record when and who edited it. In addition, because the history is managed for each input item, it is possible to quickly investigate any problems that arise.

What's great about i-Reporter

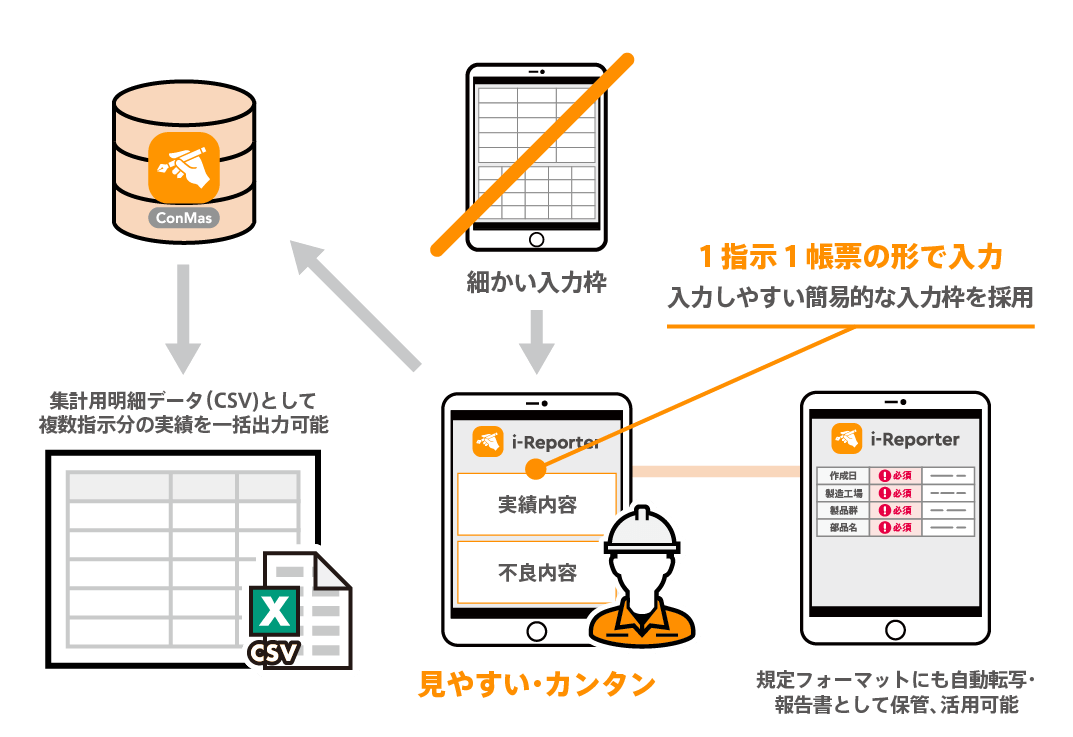

Automatic creation of instructions/reports

In addition to distribution, automatic organization is possible.

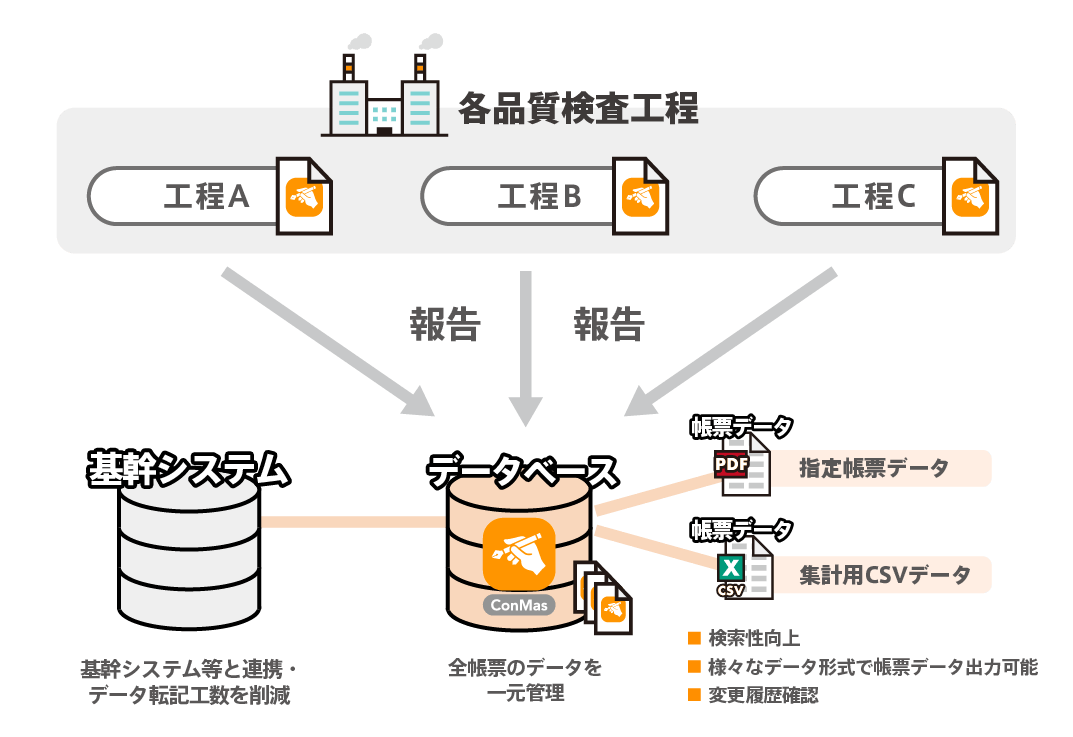

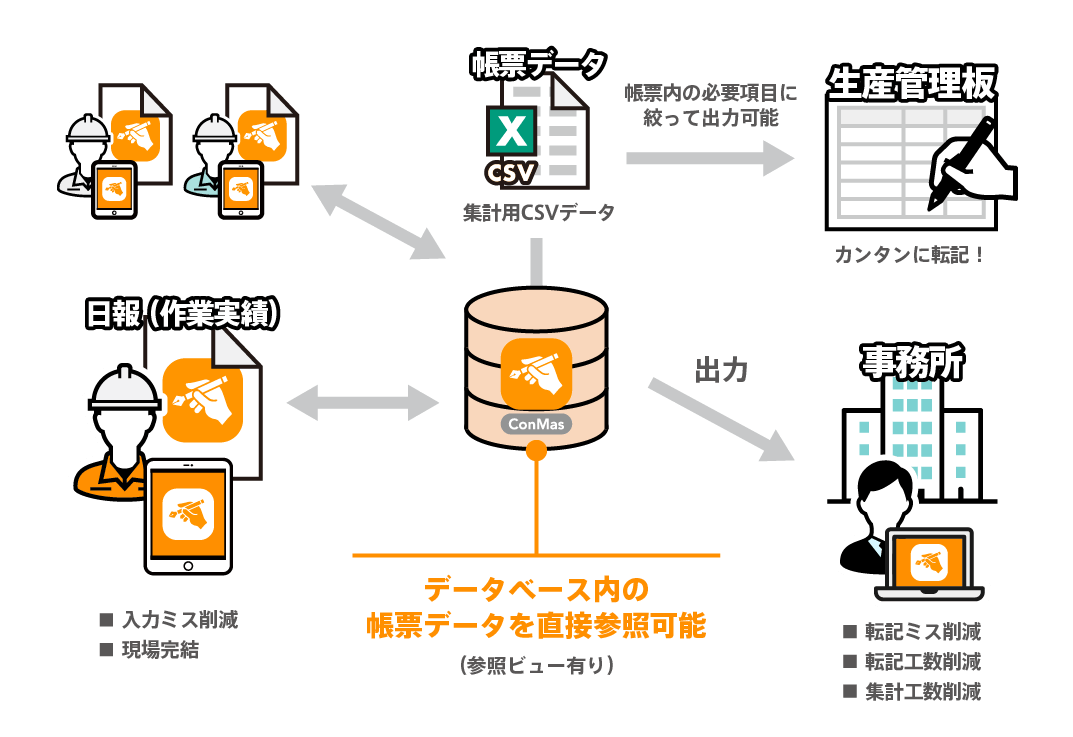

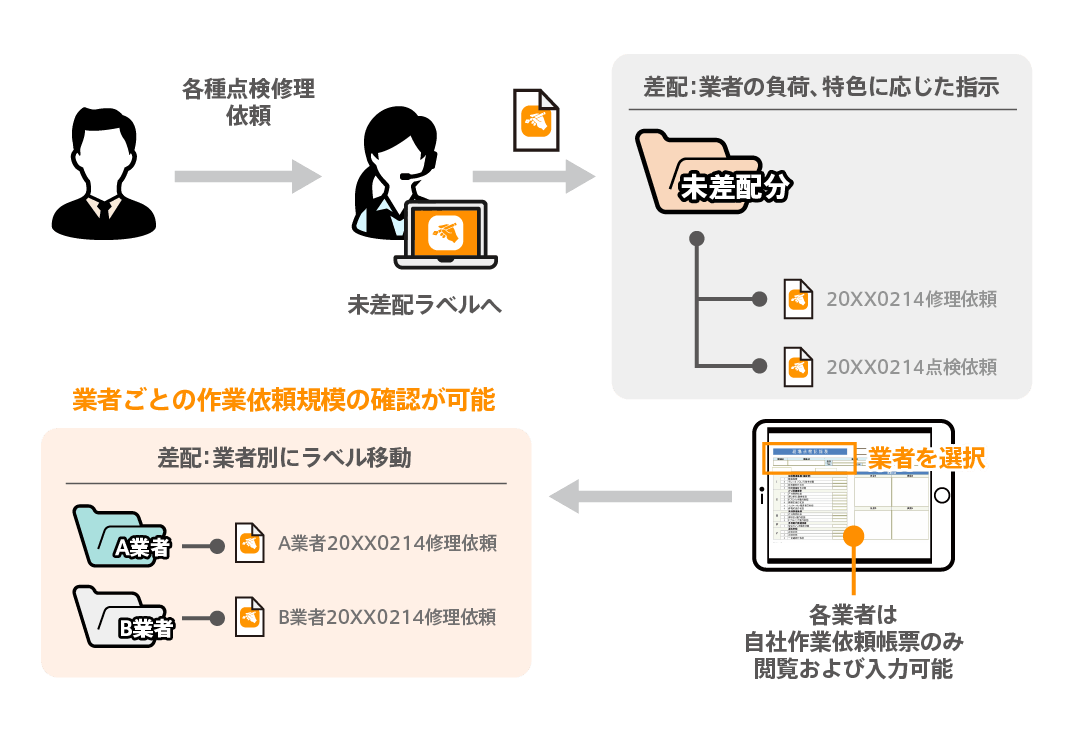

By digitizing daily reports and forms, troublesome paper-basedNo need to create and distribute paperwork.

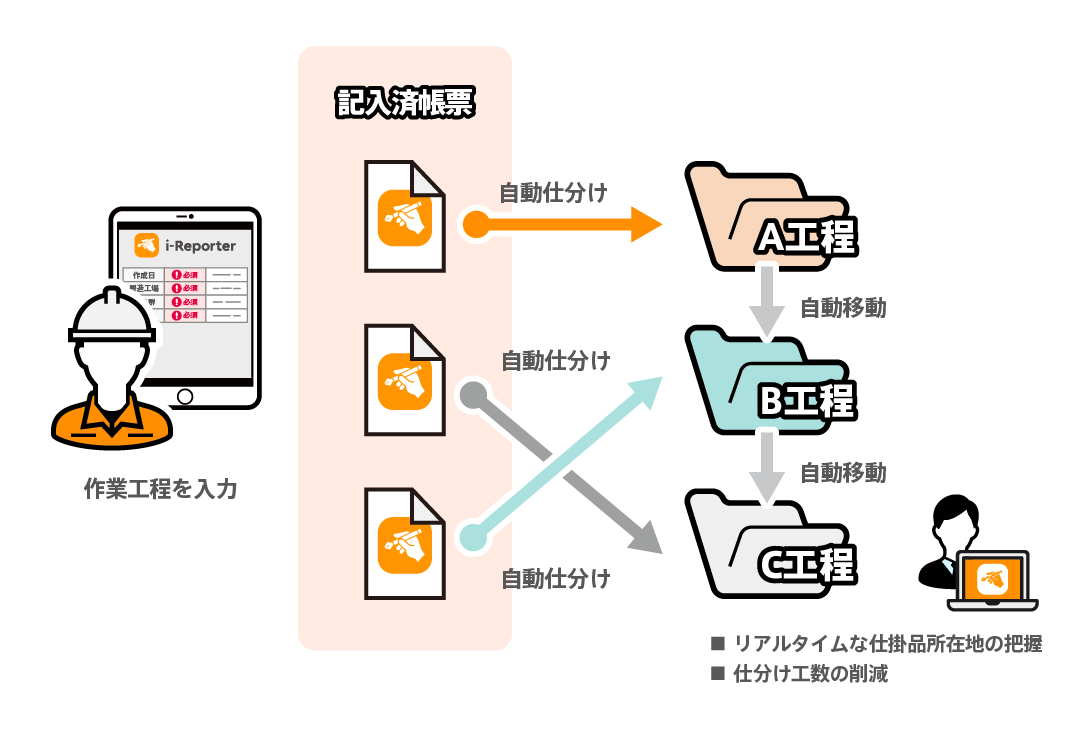

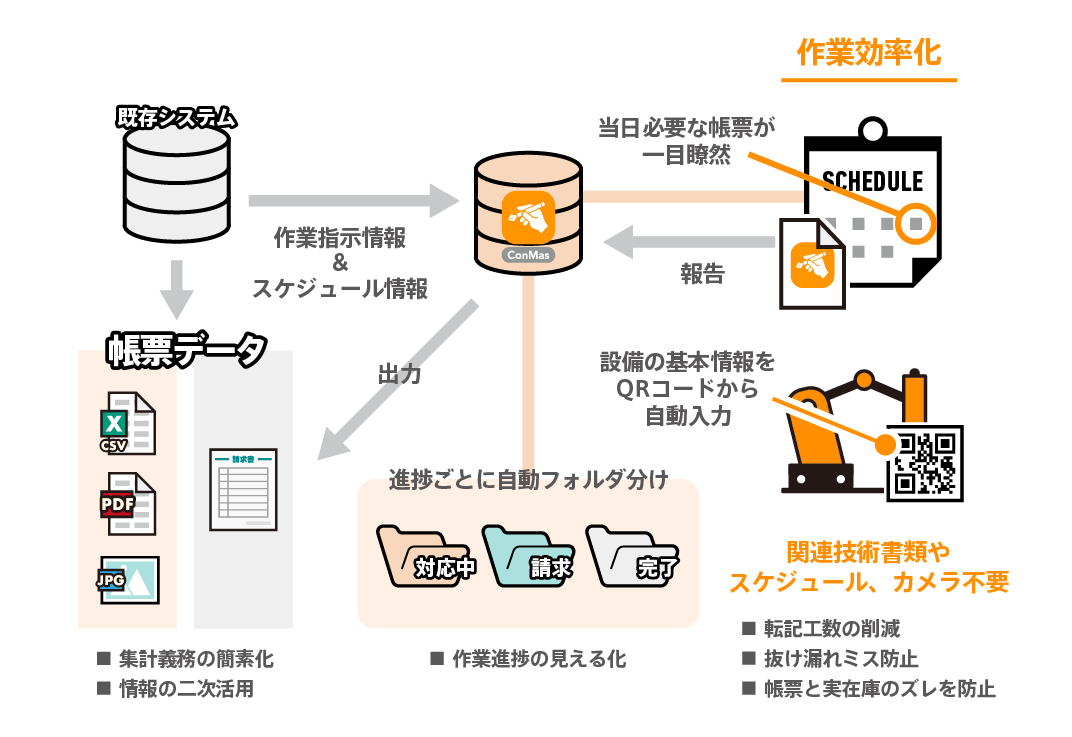

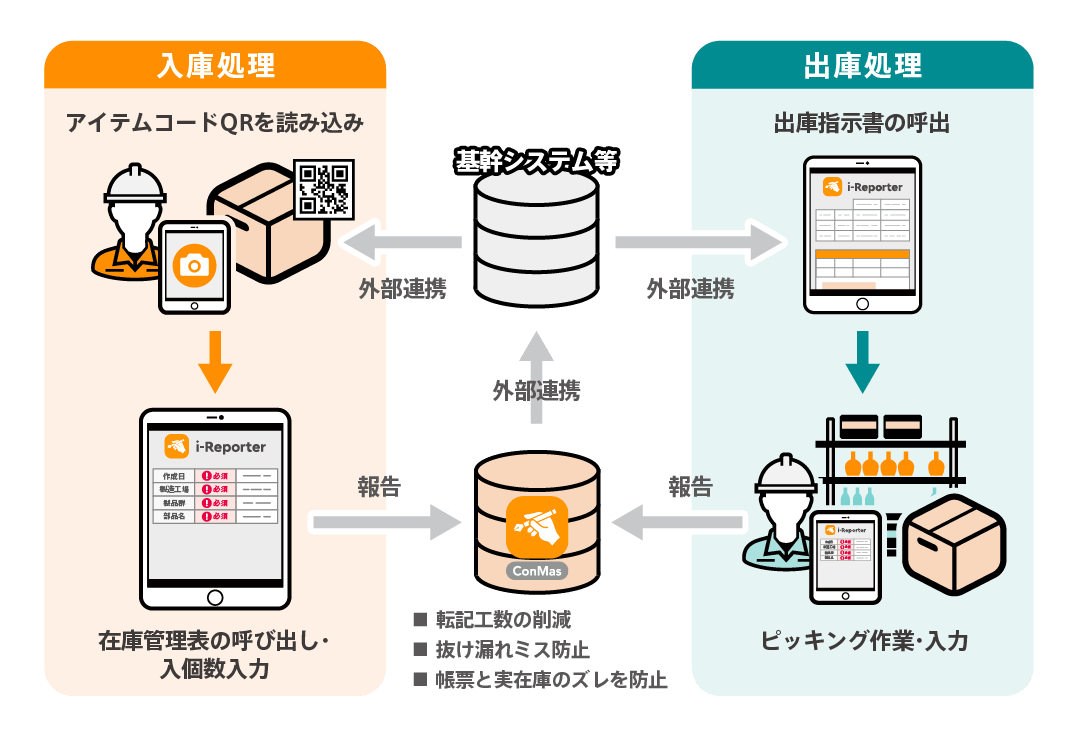

Data from higher-level systems is automatically linked to i-Reporter, allowing for the automatic creation and distribution of work instructions and daily work reports in folders for each worker. Input forms can also be automatically organized into folders according to the input values in the form (company name, date, status, etc.).

What's great about i-Reporter

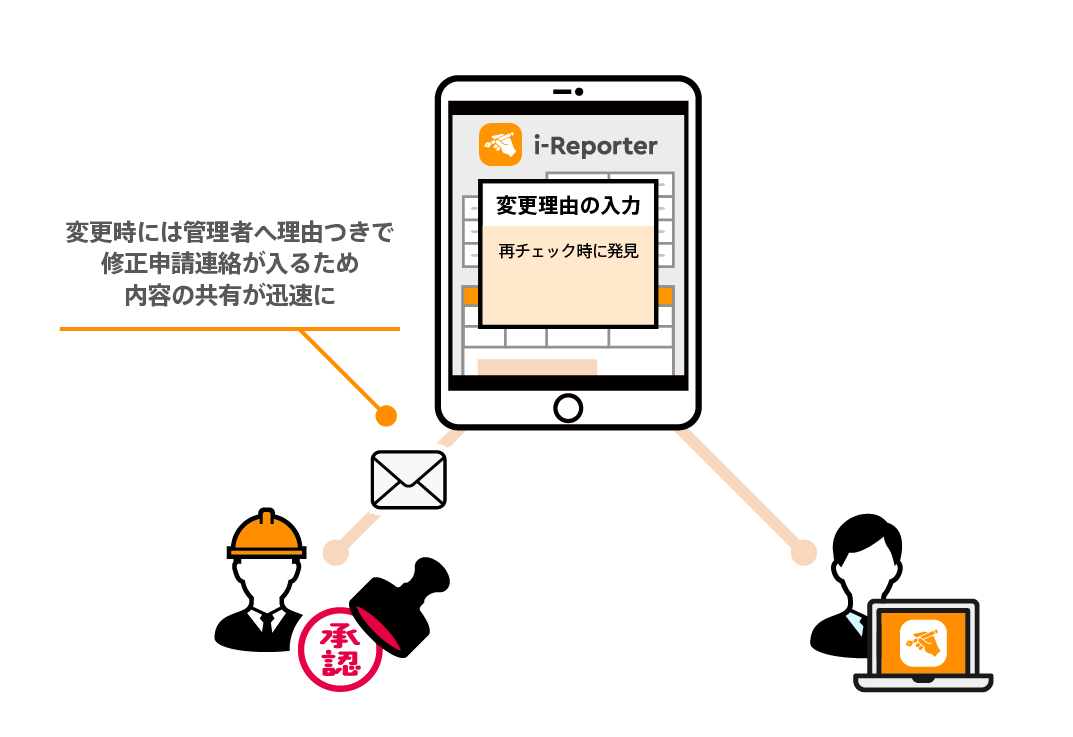

Approval and reporting of documents and records

No need to move.

Automatic notifications via chat and email!

Eliminates the hassle of calling internally or in personReduce indirect work with quick communication!

The workflow function can be used to automate approval requests for records and reports entered on-site. Confirmation with the relevant department or superior can be done without moving. Notifications to relevant parties can be set up via chat or email, eliminating the need to send emails or report via internal lines or in person.

*Some functions require integration with i-Repo WorkFlow (optional function).

Key Features

-

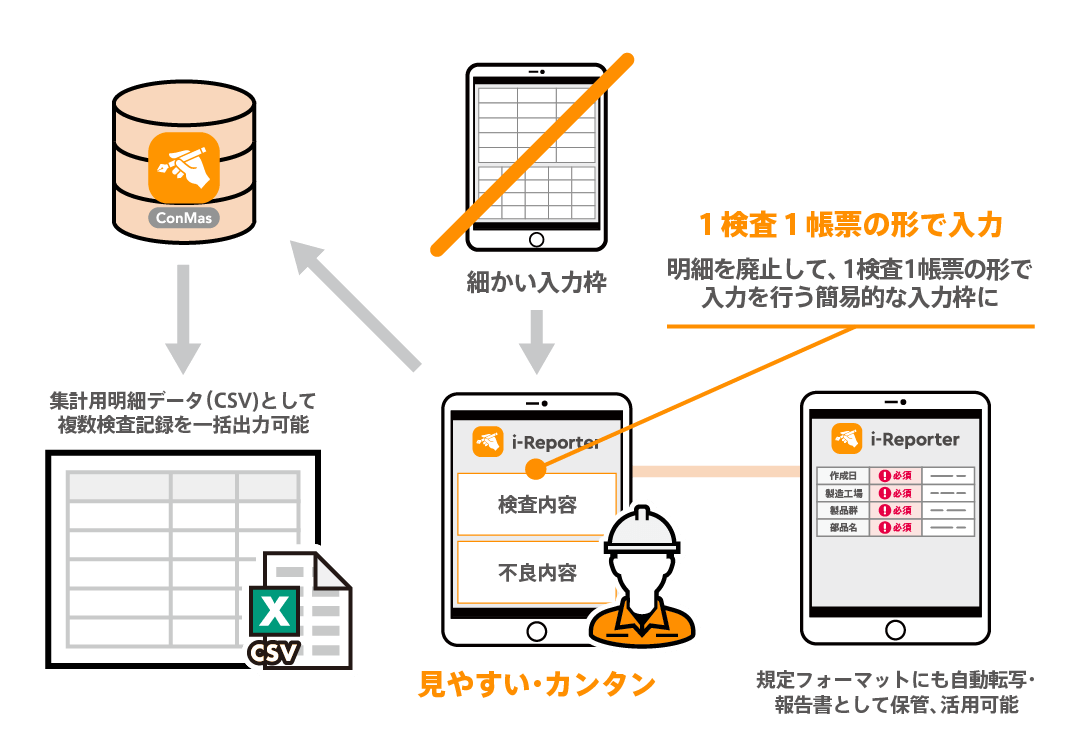

Creating/entering reports

We have thoroughly pursued creating reports that are easy to read and understand, allowing field workers to input data easily and without making mistakes.

Learn more -

Form design

(Create a template)Convert your familiar Excel forms into electronic forms. After you start using the system, you can easily change the form layout or add items in Excel.

Learn more -

Form Management

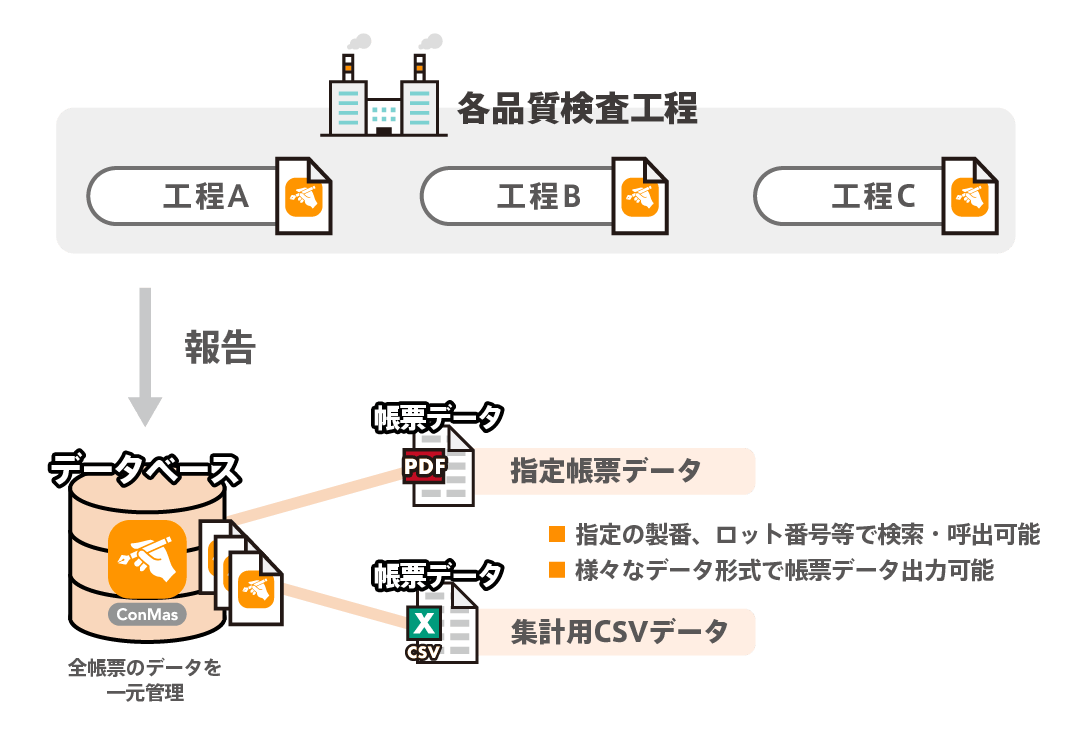

The data of the created reports is centrally managed by the system, and reports can be viewed, edited, and printed from the web management screen.

User authority management and security measures are also in place.Learn more -

System Integration

It has a wide range of functions for linking data with external systems. It automates processes such as tabulation, reporting, and analysis after inputting forms, significantly improving work efficiency.

Learn more

Features especially recommended for quality inspection and inspection work

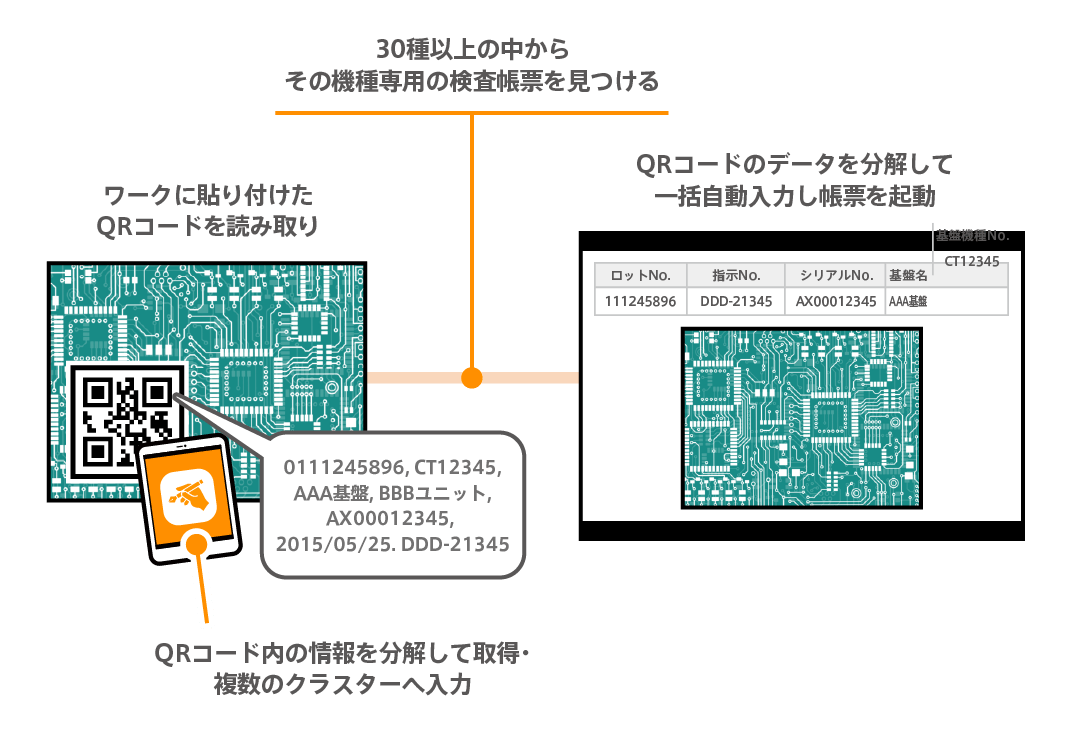

Abundant input assistance functions

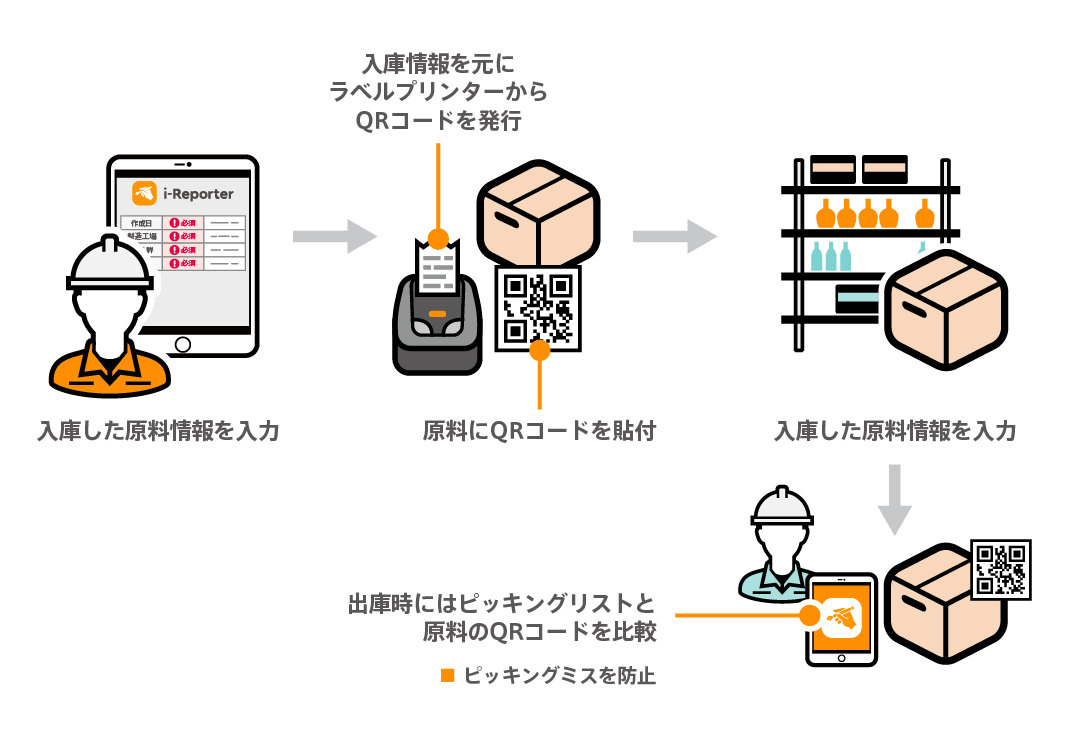

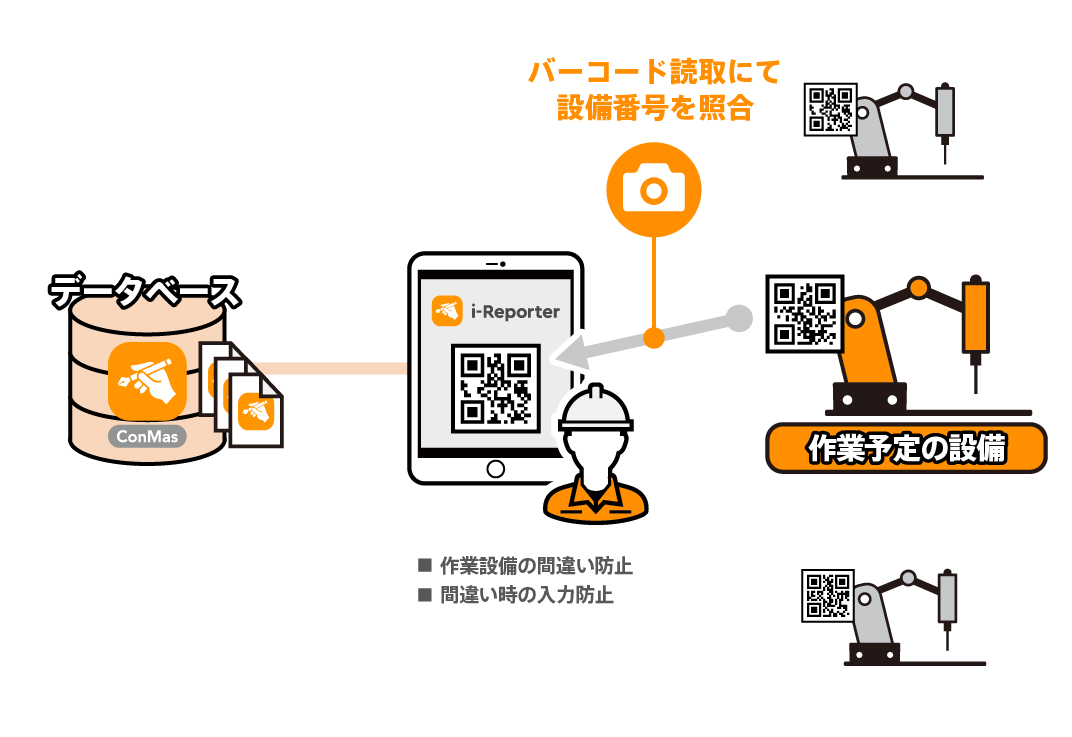

There are many input formats available, including text, numbers, options, dates, etc. Input using barcodes and QR codes is also possible.

Not only does this reduce the variation in input content and input errors between workers, it also speeds up input and makes work more efficient.

Photo taking and writing function

There is no need to transfer photos taken with a digital camera; you can complete the entire process from taking photos to pasting them into the photo ledger on a single tablet device such as an iPad. It is also easy to take handwritten notes on the site condition and any issues that need to be addressed.

Any drawings or documents you have written can also be digitized.

Function to prevent inspection forgetting and inspection mistakes

It is possible to display an alert if any information is left out in a report, and to set thresholds for inspection items, so that omissions and mistakes can be noticed immediately.

If an abnormality is found in the inspection target, the worker can be notified on the spot, allowing them to report and consult with relevant parties early on.

Automatic calculation using formulas

By importing Excel formulas*1, i-Reporter automatically calculates values and judgments. It can also handle calculation errors and complex alert conditions.

*1 Please contact us for the corresponding calculation formula.

Sign function

After the inspection is complete, signing and stamping can also be completed on the tablet.

In addition to checking the handwriting, evidence such as the location and time of recording is also recorded.

Automatic sorting function, document search function

Reported documents can be automatically sorted according to various rules, such as by person in charge or date.

Searches can also be performed by customer, facility, date, etc., improving searchability.

According to the report content

Automatic email notification function

It is possible to automatically send email notifications to relevant parties based on input values and conditions, such as inspection details and numerical values written in the document.

You can create multiple customizable notification email templates.

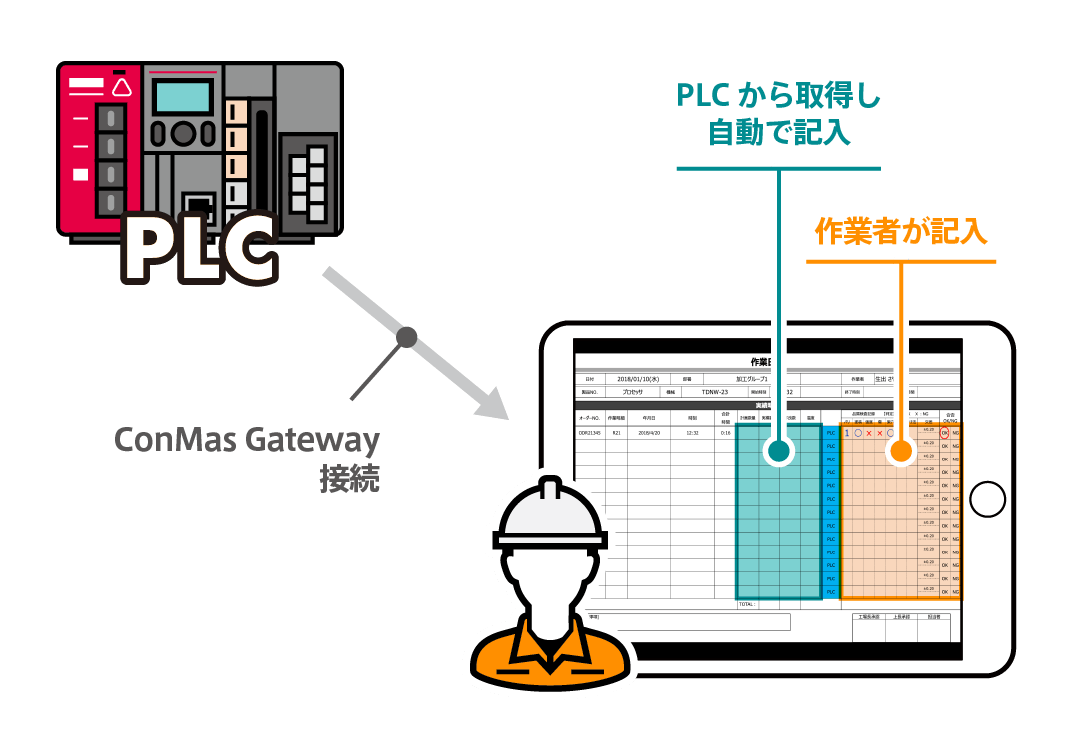

Cooperation with PLC

PLC information can be automatically imported, preventing omissions and incorrect numerical entries.

It also reduces post-processing work such as transferring data to Excel, tallying data, and inputting data into the core system. Equipment data can be easily understood and processed within the ledger, improving the speed and accuracy of data analysis.

Examples of problem solving by industry

Download it now for free!

Prevented by using on-site documents

Complaint and recall cases

We will introduce actual complaints and recalls and how to solve them by digitizing field reports.You can download materials that explain the process using specific examples.

What you'll learn from this document

- The Importance of Shop Floor Reports in the Manufacturing Industry

- Actual complaint and recall cases(Cases of record-keeping errors, storage issues, and delayed reporting)

- Solution with "i-Reporter" that digitizes on-site documents

Feedback from customers on the ground

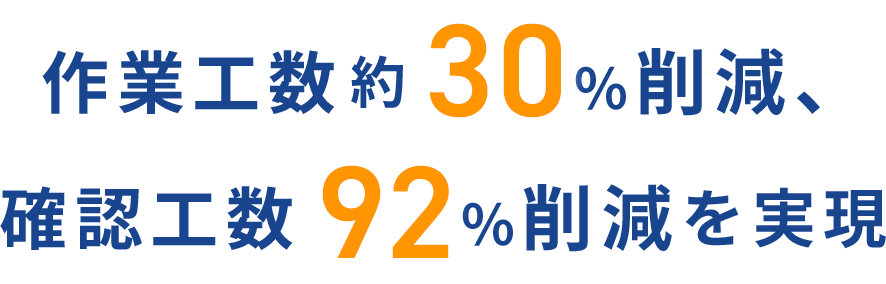

By introducing i-Reporter, we have succeeded in reducing work hours by approximately 30% and confirmation hours by 92%. The cardboard boxes used to store paper used to expand by 1 m2 each year, but now they are zero. The freed up space can now be used as a work area, which not only improved work efficiency but also allowed us to successfully reduce the number of printer counters by 20%. This has been very well received by on-site workers.

Received from ITreview

Customer Reviews

i-Reporter's track record

Over 4,500 companies have adopted it!

No.1 share in paperless apps

-

Site reports

Paperless Solutions

Domestic market volume

Achieved the top market share of 48.6%! *1

In the manufacturing and machinery industry

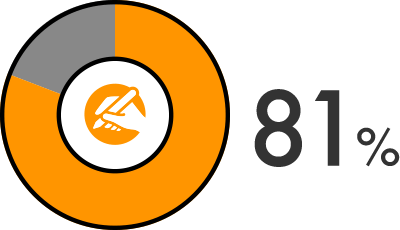

Evaluation by employees of small and medium-sized enterprises

function Satisfaction with *2

Large corporations

Evaluation by people working in information systems

Ease of implementation Satisfaction with *3

*1 Source: Fuji Chimera Research Institute, Inc. published on August 8, 2024, IT Investment/Digital Solutions Market by Industry, 2024 Edition I-2, On-site Paperless Document Solutions Market Share: 48.6% (Vendor Share and Volume in FY2023)

*2 Data details: As of July 13, 2023. Calculated from the percentage of ITreview reviewers who gave a rating of 4 out of 5 for satisfaction with the functionality. Job type: Manufacturing/machinery, Company size: Small and medium-sized enterprises. Number of respondents: 12.

*3 Data details: As of July 13, 2023. Calculated from the percentage of ITreview reviewers who gave the ease of implementation a score of 4 out of 5. Job type: Manufacturing/machinery, Company size: Small and medium-sized enterprises. Number of respondents: 12.

-

Implementation track record

Number of contracted users

Over 220,000 people!

As of May 2025

-

ConMas i-Reporter

Thanks to you

Adopted by 4,346 companies!

As of May 2025

Flow of implementation

You can consider introducing the product after seeing an explanation and demo of the actual product.We provide thorough support from specific consultations at the consideration stage to implementation and operation support.Please feel free to contact us.

-

Request information

-

Product DescriptionSeminar

-

Operation training session &

Free Trial -

Contract

-

Service launchsupport

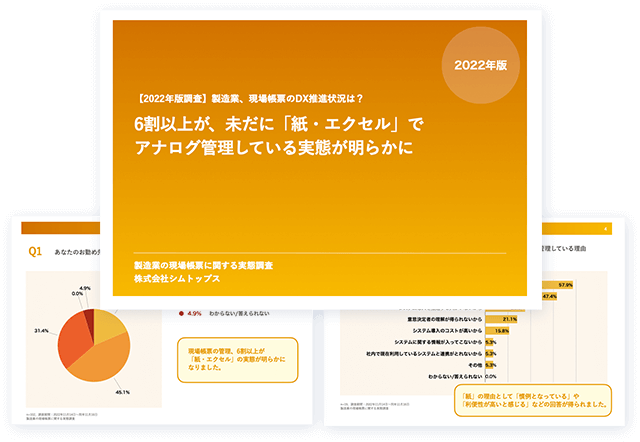

The survey results can be downloaded for free!

Manufacturing, field reports

What is the status of DX promotion?

Regarding the actual survey of on-site document management in the manufacturing industry,You can download materials that provide a visual analysis of usage and issues.

Examples of survey results that can be seen in this document

- Ranking of methods for managing site documents

- Ranking of reasons for managing on-site documents on paper

- Ranking of reasons for wanting to proceed with electronic forms

Frequently asked questions

システムの提供形態は何がありますか?

システムの提供形態は何がありますか?

We can provide either cloud services or on-premise services. Please choose the option that best suits your needs.

For more information, please contact your local distributor or CIMTOPS.

導入前にトライアルすることは可能ですか?

導入前にトライアルすることは可能ですか?

All features are available free of charge for up to 100 users for two months. The trial can be run on cloud or on-premise. For details, please visit the i-Reporter free trial page.

操作講習会などの教育はありますか?

操作講習会などの教育はありますか?

We are preparing free in-person training sessions (Tokyo, Kariya, Kyoto) and online training sessions for customers who are considering introducing our products or who have already purchased them. Please contact CIMTOPS or your local distributor for details.

自社業務システムや各種クラウドサービスとの連携は可能ですか?

自社業務システムや各種クラウドサービスとの連携は可能ですか?

You can use the API for external system integration and ConMas Gateway to integrate with business systems and various cloud services. For details, please contact CIMTOPS or our agents.

Company Profile

CIMTOPS Corporation. provides production management schedulers, process control systems, and on-site report systems.We are a domestic package manufacturer with a strong track record of software that supports the digital transformation of the manufacturing industry.

-

For individual order production

Production scheduler/process control system

-

Bill of Process (BOP) Tool

- Company name

- CIMTOPS Corporation.

(English notation: CIMTOPS Corporation.)

- Establishment

- October 1, 1991

- President and CEO

- Takashi Mizuno

- main office

-

〒141-0021

東京都品川区上大崎2-25-2

新目黒東急ビル10階

TEL:03-5721-4610

FAX:03-3491-4610

- Location

- Chubu Area Office (Kariya)

Kansai Area Office (Kyoto)

- Abroad

- Xinmu Tuosi (Shanghai) Information Technology Co., Ltd.

CIMTOPS SG LAB Pte. Ltd.

Implementing company

Over 4,500 companies have adopted it!

Paperless app

No.1 share

Manufacturing

Quality inspection and inspection work to make it more efficient On-site document electronic system