Customer Stories: Fuji Xerox Manufacturing Co., Ltd.

Fuji Xerox Manufacturing Co., Ltd.

i-Reporter use case and case study: Fuji Xerox Manufacturing Co., Ltd.

Fuji Xerox produces a diverse range of document solutions, from large format printers for the printing industry to multifunction printers for the office. Fuji Xerox Manufacturing is the sole company in Japan involved in assembling such devices and manufacturing consumable goods such as toner.

The main function of Fuji Xerox Manufacturing’s Suzuka Center in Mie Prefecture is the production of the core parts for their copy and printing machines as well as environmentally friendly recycled products. A major challenge that the center had long grappled with was the management of the large amount of paper-based daily reports that the manufacturing plant produced and the reduction of the time required for their input as data. So, how did this company solve a problem that many manufacturers must also be grappling with?

This article examines the document digitalization project that the Suzuka Center embarked on to address this issue, based on discussions with the company’s Center Manager Mr. Masaharu Furukawa, Mr. Toshiki Tanaka of the Demand Management Department Information Process Improvement Group, and some line managers in the factory workplace.

Mori (Right), the department leader at the time who drove the introduction of i-Reporter, and current department leader Mr. Mori (Right) and i-Reporter user Mr. Yamao (Left). The impetus for the introduction of i-Reporter into the department was Mori’s discussion with Tanaka after they bumped into each other in the locker room.

Elimination of Time Needed for Data Entry

In the past, work process management entailed the collection of paper-based daily reports written by all workers and their input into an Excel spreadsheet back at the office. The major issue with this system, however, was the large amount of valuable time that it consumed.

“The manufacturing industry in the Tokai region is experiencing a severe labor shortage at the moment. The lack of workers at the Suzuka Center is an issue that has been going on for quite some time. As such, we were looking for a way to enable our valuable human resources to productively engage in their work without spending their time collecting and inputting the daily reports, which are necessary but non-productive in and of themselves.” (Mr. Toshiki Tanaka)

At the time, each line leader was spending more than an hour every day inputting the day’s production results into the system. In addition to the time that this work took there was also the risk of input errors occurring during the transcription process. Mr. Tanaka and the line leaders on the factory floor shared the desire to reduce both aspects to the greatest possible extent.

Quality Losses Caused by Time-Lag Induced Delays in Decision-Making

The time and work involved in digitizing the reports also had a significant effect on quality. As noted above, the use of paper reporting necessitated a “collect, input, aggregate” procedure for data analysis. As such, final results were not available until the following day at the earliest, with a further two to three days required for investigating issues and deploying remedial measures. During this period, in other words, the production process would continue without problems being addressed. The ability to drastically cut this time lag, identify problems in real time, and implement countermeasures on the spot to effect improvements would be a powerful tool for increasing efficiency and quality.

i-Reporter in use in the department which produces large format printers for the professional use. Photographs taken with the tablet can be attached to the digitalized report form. Problem areas can also be spotted at a glance.

In Search of Adaptable Digitalization

A variety of collection methods including OCR and digital pens were considered at the time but their respective pros and cons meant that a good fit for the workplace was hard to find. Tablets for viewing and filling-in digitalized documents, however, would be a suitable option in a work environment with limited space and a lot of time spent standing. Furthermore, a tool for real-time data collection and aggregation would eliminate time spent on collecting, transcribing, and aggregating the reports, enabling understanding of the current situation without a time-lag.

“In workplace improvement it is IE and QC-focused improvement, not a “sudden IT-ification”, that is most important. IT is just one way of getting to desire result. Conversely, the challenge when working with IT systems is that it is not possible to react quickly to changes due to the fact that things like altering programs take a lot of time without the involvement of consultants and development firms.” (Mr. Toshiki Tanaka)

In his search for a solution to this challenge Mr. Tanaka was introduced to ConMas i-Reporter, a product offered by Cimtops Corporation.

Mr. Tanaka recalls – “i-Reporter is also marketed by our parent company , Fuji Xerox. When we were researching potential tools I had the opportunity to talk with someone from sales there who strongly recommended we take a look at it as something that could be of use.” But of course i-Reporter was not selected simply on the basis of this recommendation. The selection was based on the results of a review of a number of aspects including functionality, performance record, and security. The decisive factor, however, was its high level of adaptability.

“Specifically, with regards to the creation of input forms for the tablet we placed importance on the ability to develop things quickly and with no programming or special skills needed” notes Mr. Tanaka. Depending on the state of the improvement process the types of data needed on the factory floor change quite frequently. While it is possible to deal with some aspects in-house, if complex programming is required each time the input form is changed then the development time and costs involved make it very difficult to quickly adapt to changes on the factory floor.

“Since we were trying to find something that would reduce time wastage we especially wanted to find a tool that was capable of being used without the need for programming. i-Reporter performs extremely well in this respect. That’s the key point.” (Mr. Tanaka)

Digitizing, Precisely Because It Is More Convenient Than Paper

The introduction of i-Reporter resulted in the 80 minutes daily that was being spent on paper collection and data entry being almost totally eliminated. This is because the details entered into the tablet by the workers are immediately transformed into data.

Based on these results Mr. Tanaka was confident in moving forward with the i-Reporter implementation project. Adoption within the company, however, did not go exactly as he had envisioned.

“Compared to paper, the input fields on a tablet are smaller and harder to use. A simple transposition of the layout of the paper form will not be user-friendly and thus not be adopted in the workplace.” (Mr. Tanaka)

Mr. Tanaka notes that the key to successful digitalization is for it to be “more convenient than paper”. Luckily, i-Reporter is equipped with a variety of features and settings to enable this. The factory floor leaders, workers, and Cimtops representatives put a lot of thought into finding a way to utilize them so as to make this a reality.

Mr. Mori from Fuji Xerox Manufacturing’s Second Manufacturing Department, who worked with Mr. Tanaka on the digitalization project, reflects – “The user input interface, in particular, was very carefully researched. We designed it so that work start time, for example, can be entered automatically with one touch, right at the point when work begins. There is also a wealth of other ideas for reducing the time and effort related to input including the ability to select from a list without using the keyboard, automatic item transition, and functionality whereby the lot number can be read into the system from a barcode. All of this must have given the Cimtops team a pretty hard time.”

The current version of i-Reporter includes a significant number of new features that grew out of the project. Cimtops CEO Takashi Mizuno comments – “There have been more than a few companies that have decided to use i-Reporter on the strength of the features that were developed”.

Another aspect is the fact that the large amount of standing time involved in factory work means that using the tablet’s software keyboard involves extra work and increases the error rate.

“Input errors attract negative attention from superiors, which is a large source of stress for those doing the inputting. If a tool makes it possible to carry out input work as easily and as accurately as possible then people will be able to experience for themselves that it is an improvement over a paper-based system. This type of fine-grained improvement is important.” (Mr. Tanaka)

Additionally, efforts were made to proactively gather support from those on factory floor through in-house i-Reporter information sessions and opportunities to view production lines that were trialing the system.

In the early stages of the implementation period it was apparent that older employees were more resistant to the i-Reporter digitization project. The efforts described above, however, led to usage gradually increasing among younger employees. Now, Mr. Tanaka says that almost all workers, including longtime employees, are giving him feedback that the system is “easier to deal with and more convenient than paper”.

Suzuka Center’s Second Manufacturing Department, which mainly produces printed circuit boards for printers, etc. In the past, line leaders would spend approximately one hour a day inputting production results but the introduction of i-Reporter has reduced this to almost zero. Additionally, user-friendly features displays with enlarged buttons, for example – have been implemented for ease of input even when working in a standing position.

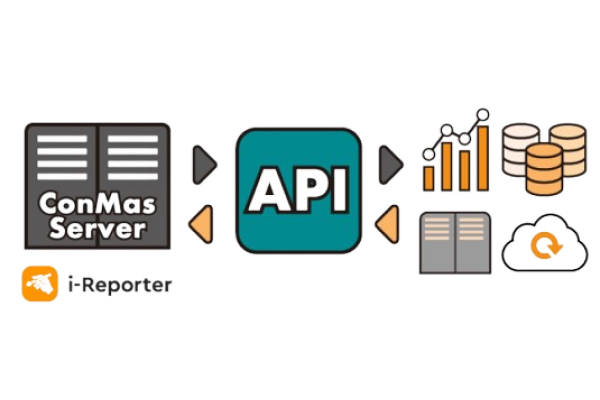

Another addition involved linking i-Reporter with the BI dashboard “MotionBoard” from WingArc1st Inc. to enable visualization of data collected in real time. The past twenty-four hour’s worth of data is automatically aggregated, faults are able to be quickly detected, and KPIs for investigating their probable causes are displayed in real time. This has resulted in a system which guards against continued defect production.

Even though the digitalization of reporting through i-Reporter has resulted in significant time savings and enabled real-time situation analysis at Fuji Xerox Manufacturing Mr. Tanaka has his sights set on further improvements.

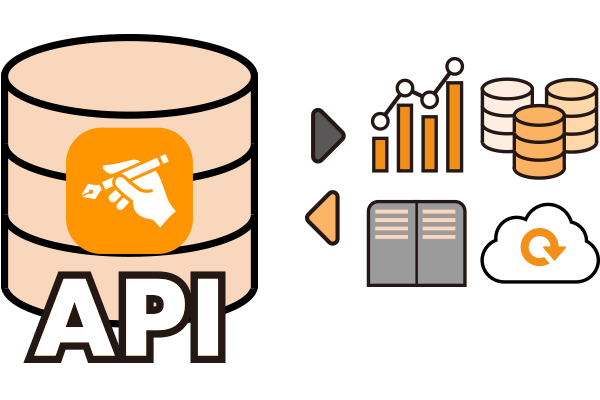

“In the next stage I would like to investigate linking i-Reporter with our core system. Doing so would increase the utility of our data and further decrease time spent on data entry on the factory floor.”

As Mr. Tanaka notes, there are a number of developments for the utilization of IT systems for the manufacturing industry under consideration at the Suzuka Center. Center Manager Mr. Masaharu Furukawa explains:

“Fuji Xerox Group does not just sell products such as multifunction devices and printers. We are advocates for business process and workflow innovation and the pursuit of the creation of new value. As such, we are able to create new value and deliver it to our customer by developing solutions to the challenges that we, as those responsible for manufacturing in our group, come up against. Looking ahead, for example, I would like to focus on things like IoT and make predictive management, which enables knowledge of what will happen in the future, a reality. I would like to engage with users in carrying out this kind of cutting-edge research. That’s what I’m thinking.”

Fuji Xerox Group is an organization which can execute improvements from within and work to provide solutions and services based on such experiences. Similar to the digitalization case study described in this article it is likely that the new value developed by this firm will have a large impact on the manufacturing industry in the near future.

Corporate Profile

Fuji Xerox Manufacturing Co., Ltd.

Companies in various industries and sizes have deployed

i-Reporter in their businesses.

Ranked the number 1 paperless form solution in Japan by marketshare!

-

-

Use your existing paper forms or Excel forms as electronic forms on the go.

The best digital form solution for your business.