Main contents of inspection work | Common issues and tips for working efficiently [Inspection table template included]

table of contents

Inspection is an important part of maintaining product quality.

The quality of products and services is greatly influenced by how inspection work is done, so it is a task that should never be overlooked, but not all companies are able to carry out inspection work in the correct way.

In this article, Overview and importance of inspection work I will explain in detail.

In the second half of the article, we will also introduce the challenges that inspection work faces and tips for carrying it out efficiently, so please read on if you are involved in inspection work, such as a warehouse manager or inventory control officer.

What is inspection work?

To understand what inspection work involves, let's take a closer look at what it involves and why it's important.

Checking whether the quantity and quality are correct

Inspection work is the job of checking whether there are any problems with finished products or incoming and outgoing products at manufacturing or logistics sites.

Specifically, at factories and logistics warehouses, we check to see if there are any errors in product quantities or part numbers, as well as whether there are any quality issues such as damage, defects, or malfunctions.

Inspection work is carried out at the time of shipment or as needed during the work process, and the inspection items vary depending on the object and purpose of the inspection.

Main inspection tasks performed at manufacturing and logistics sites

There are various types of inspection work carried out at manufacturing and logistics sites.

Defective product inspection

Defective product inspection is the process of checking whether there are any defective products mixed in with the products.

No matter how highly precise the machinery used, there will always be a certain number of defective products among the products produced in the factory.

At the manufacturing site, products are checked for defects based on the manual, and any defective items are removed as soon as they are discovered.

Operation inspection

Operational inspection refers to the process of checking whether electronic devices are working properly.

This operational inspection not only checks for malfunctions in products, but also checks for bugs in smartphone apps, etc.

Contamination inspection

Contamination inspection is the process of checking whether or not a product has been contaminated with foreign matter.

In particular, when it comes to food-related products, contamination with foreign matter poses the risk of causing health problems, and in the worst case scenario, it could lead to a voluntary recall of the affected products.

Inspection work must be thorough so as not to damage customer trust or cause major damage to the company.

Quantity and measurement inspection

Quantity and light inspection is the process of checking whether there are any errors in the quantity of goods or products.

This is often done at the time of shipment and receipt, and the numbers are checked against the invoice to ensure they match.

Unpacking and inspection

Unpacking and inspection involves opening boxes or cardboard boxes containing products and checking the condition of the contents.

We check that the quantity and product number packed in the box are correct. This is done not only when products arrive, but also to check returned products.

Why inspection is important

The reason why inspection work is important is to prevent mistakes, missing items, and incorrect shipments during shipping and receiving.

In industries such as manufacturing, logistics, and retail, it is no exaggeration to say that the products delivered to customers are directly linked to the company's credibility.

The release of defective products or delays in delivery will damage customer trust and may even result in the suspension of business.

Inspection work is an essential task in order to avoid risks such as shipping defective products, products that are different from the order, and delivery delays due to inventory shortages.

Inspection work flow

Inspection work is mainly divided into two stages: when goods arrive and when they are shipped. Here we will explain the specific flow of each inspection process.

Inspection work at the time of arrival

The inspection work at the time of arrival is called arrival inspection, and is carried out when goods or products arrive from factories or suppliers.

When the goods or products arrive, check them against the delivery note to make sure the quantity and product number are correct. At the same time, visually check for any initial defects such as damage or dirt.

If there are no problems with the inspection results, please hand the receipt to the delivery person and receive the product. Upon arrival, the delivered items may be unpacked and inspected in cardboard boxes to check for any discrepancies in quantity or product number.

Inspection work at the time of shipment

The inspection work that takes place during shipping operations is called shipping inspection, and is generally carried out before shipping goods or products to business partners.

During inspection at the time of shipment, check that the quantity and product number match the shipping instructions. After that, check that there are no errors in the specifications of the products or items to be shipped, and that there are no quality issues. At the same time, make sure that there are no mistakes in the recipient's name or address.

Main issues in inspection work

Due to the nature of inspection work, which must be carried out carefully and accurately, several challenges exist.

Heavy burden on workers

Although the inspection work itself is simple, it requires concentration and attention when checking the quantity, part number, quality, and performance of products in detail.

It is quite possible that personnel and time will be required for inspection work at the time of shipment and that this will put pressure on the company's main business.

Keep in mind that inspection work may reduce the efficiency of your entire business.

Inspection work is costly

Inspection work requires the deployment of inspection staff, which increases costs such as labor and equipment costs.

To ensure high-quality inspection work, double-checking or triple-checking by two or three staff members may be necessary.

Furthermore, if you introduce an inspection system or equipment to improve business efficiency, you will incur installation and running costs.

In this way, investing too much in labor costs and equipment costs for inspection work can become a huge burden for companies.

Human error cannot be prevented

Visual inspection is prone to human error.

The main causes of human error during inspection are as follows:

- Mixing up similar products or part numbers

- Overlooks small scratches and defects

- Inspection procedures and accuracy vary depending on the worker

- There are too many things to check

When handling large quantities of goods, you may need to hire part-time or temporary employees who have no experience in inspection work.

Even for the most experienced employees, it is difficult to completely eliminate inspection errors, so if no measures are taken, the risk of errors occurring remains high.

Let's understand that inspection is prone to human error and consider the necessary countermeasures.

Tips for efficient inspection work

Here are some tips for carrying out inspection work efficiently.

Review work flow

In order to make inspection work more efficient, it is important to review the work flow. By eliminating unnecessary movement and effort by workers, work efficiency can be improved.

Examples of initiatives to review work flow are as follows:

- Plan the process from receiving goods and products to inspection and storage so that it can be completed with minimal movement.

- Ensure ample work space

- Keep frequently used tools and lists within easy reach

By creating an environment that is easy to work in, we can reduce the burden on workers and their working hours while also aiming to improve efficiency.

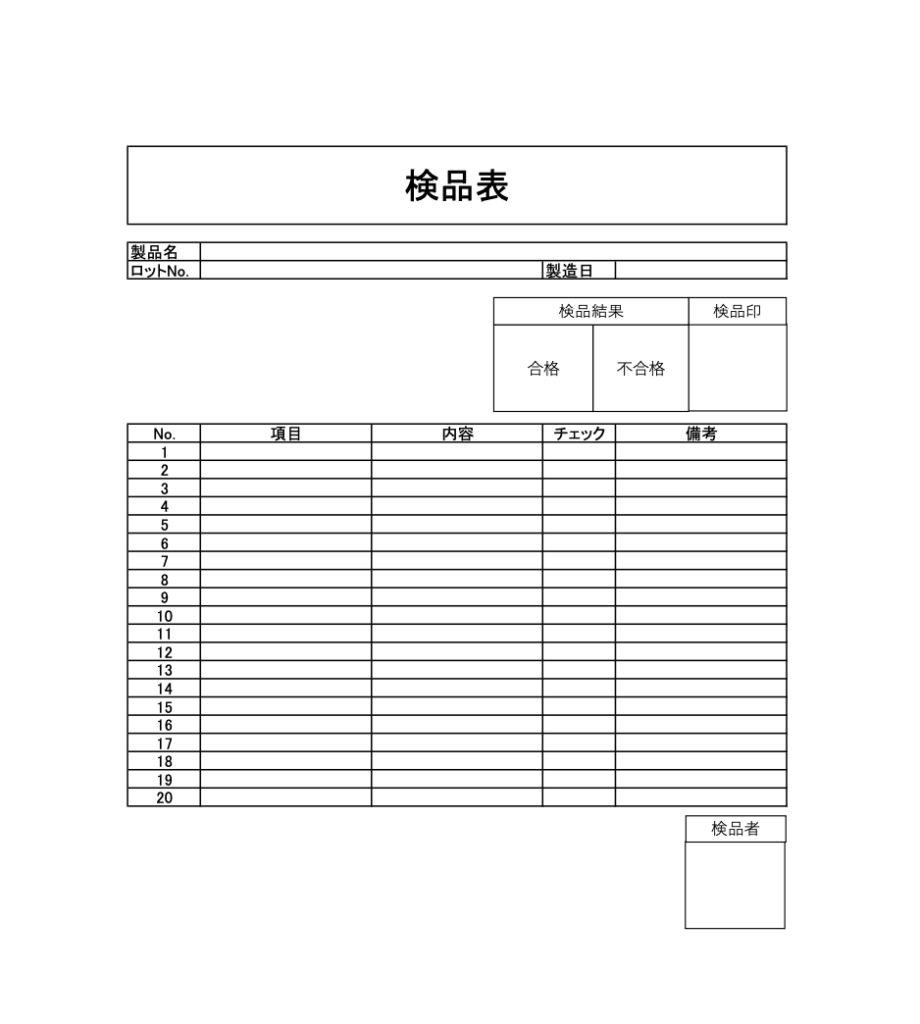

Create a manual for check items and work procedures

Consider creating a manual for the check items and work procedures during inspection work.

Since inspection work can be carried out to the same standards regardless of which worker is in charge, we can expect to see a reduction in human error.

The following items should be included in the manual:

- Items to be inspected

- Tools used

- Judgment criteria

- Recording method, etc.

If you create a manual, you can use it to train new workers.

<Download the inspection sheet template here>

Use barcodes and two-dimensional barcodes

By attaching barcodes or two-dimensional barcodes to the products and parts to be inspected, manual data entry errors can be reduced and data processing can be performed more smoothly.

i-Repo Scan allows you to read multiple barcodes without the need for a dedicated handheld terminal.

It is also possible to read only pre-specified barcodes, which not only improves work efficiency but also reduces labor costs.

Use product numbers to make them easier to distinguish

In most cases, product numbers are written in letters and numbers. If different products have similar product numbers, it can lead to inspection errors.

Therefore, even if the products are similar, try to use product numbers and colors to make them easy to distinguish. For example, avoid using similar alphanumeric characters such as the letters "q" and "p" or the numbers "1" and "7," and make sure to use product numbers that make it clear at a glance that the products are different.

Let's improve the quality of inspection work and increase the reliability of the company

Many people may find inspection work very monotonous and unexciting, but it is an important task that is directly linked to a company's credibility and customer satisfaction.

If there are a lot of inspection errors, investigate the cause as soon as possible and take measures to improve the situation.

In order to avoid complaints, improve the quality of your company's inspection work by keeping in mind the inspection process flow and points for efficiency introduced in this article.

[Contributing to improving productivity and work accuracy in the logistics industry]

Improve the efficiency of on-site work with the on-site document digitization solution "i-Reporter"!

- Speedy handling of large-volume scanning tasks, significantly reducing scanning time

- Intuitive operation that is easy to use for a wide range of workers, allowing anyone to perform high-precision work

・Supports rapid training for inexperienced employees, and reduces work errors with intuitive digital forms

[About i-Repo Scan]

This application allows you to scan multiple barcodes simultaneously and continuously using an iPhone or iPad.

It improves the efficiency of inventory management tasks (inventory, receiving and retrieving goods, picking, etc.) and prevents incorrect input and delivery.

Barcode reading screens can be easily created using Excel.

It is also possible to link the read data to inventory management systems etc. in real time.

▼5 features of i-Repo Scan

① Ultra-fast scanning of large quantities of barcodes! Multiple barcodes can be scanned simultaneously and continuously.

② Identify barcodes that do not match the conditions! Prevent work mistakes

3. No missing barcodes even with a large number of barcodes! Numbers are displayed on barcodes that have already been read.

④ A dedicated UI for accurately and efficiently counting quantities, such as inventory counts and stock receipts and deliveries

⑤No need for a dedicated handheld terminal

⑥High speed and high accuracy thanks to joint development with SCANDIT, a global provider of innovative barcode solutions

▼i-Repo Scan site

https://i-reporter.jp/scan/

This is the editorial department of the Field Document Research Institute!

This blog is operated by CIMTOPS Corporation., which develops and sells the field document electronic solution "i-Reporter."

We will be delivering industry information on a regular basis to help those of you working hard to promote digital transformation in the workplace, so please take a look!