[With Excel] FMEA overview and format | Items to be included and implementation procedures

table of contents

Do you have concerns like these? "I want to solve quality and cost issues at the design stage," "I want to know how to identify potential risks in the manufacturing process in advance," "I want to prevent defects caused by human error," or "I want to minimize the risks associated with design changes"?

This article explains "FMEA" (Failure Mode and Effects Analysis), a risk management method used in product development and manufacturing processes.

We will explain the overview of FMEA, the specific implementation process, and answer frequently asked questions using diagrams and templates, so please use this as a reference for your implementation.

Overview of FMEA

What is FMEA? A systematic approach to identifying potential failures in products and manufacturing processes and analyzing their impact is.

It is mainly carried out during the product design and manufacturing process, and helps improve quality and reduce risks.

What is FMEA?

FMEA (Failure Mode and Effects Analysis) is a risk assessment method that identifies potential failure modes in products and processes and analyzes their impact.

Failure modes are specific ways in which a product or process can fail, such as "part breakage," "system error," or "human error."

The aim is to improve product quality and reliability by predicting risks in the manufacturing process and considering countermeasures at the design stage.

FMEA classification

FMEA is classified into several types depending on the scope and purpose. Let's take a look at the three main types of FMEA.

Process FMEA

Process FMEA is a method for preventing problems that may occur in the manufacturing process. It targets various elements in the manufacturing process, such as equipment, workers, materials, and procedures, and extracts failure modes that may be hidden in each element.

By implementing process FMEA, you can expect to improve the quality and productivity of your manufacturing process and reduce costs.

Design FMEA

Design FMEA is performed during the product design stage to identify potential failure modes in the product design and analyze their impact, with the aim of detecting and correcting design flaws at an early stage.

By implementing design FMEA, you can improve product reliability and safety, shorten development time, and reduce costs.

Functional FMEA

Functional FMEA is a type of FMEA that focuses on the functionality of a product or system. It analyzes the causes of loss of functionality that a product or system should have and considers countermeasures.

Conducting a functional FMEA will lead to improved product functionality and reliability, as well as increased customer satisfaction.

Advantages and disadvantages of FMEA

By implementing FMEA, you can identify problems in advance and develop countermeasures. As a result, you can expect benefits such as improved quality and cost reduction, but there are also disadvantages. From here, we will introduce the advantages and disadvantages of FMEA in detail.

Benefits of FMEA

The benefits of implementing FMEA are as follows:

• Risk management is possible before mass production is established

• Improved customer satisfaction

• Optimizing human resources and costs

Here we will take a closer look at these three benefits.

Risk management is possible before mass production is established

By implementing FMEA, it is possible to identify potential failure modes before mass production is established.

Knowing the countermeasures to be taken in advance according to the risks will significantly reduce the occurrence of defects after mass production begins, which will lead to reduced correction costs.

Improved customer satisfaction

By implementing FMEA, it is possible to improve product quality and prevent problems before they occur, thereby increasing customer satisfaction.

Optimizing human resources and costs

By preventing risks in advance, you can reduce response costs and thereby reduce countermeasure costs when problems occur.

When a problem occurs, it can take a lot of time and money to deal with it, but by eliminating risks in advance using FMEA, you can optimize human resources and costs.

For example, by using FMEA to identify risks associated with design changes in advance and taking measures, you can prevent increased costs due to rework and corrections.

In addition, by analyzing the possibility of defects occurring due to human error and taking measures such as reviewing work procedures and strengthening the checking system, it is expected that human errors will be reduced and quality will be improved.

Disadvantages of FMEA

One of the disadvantages of FMEA is that it tends to be a subjective evaluation. Because the evaluation is based on the experience and knowledge of the person in charge, it is inevitably prone to being a subjective evaluation.

If there is only one person in charge, the number of failure modes that can be assumed may be limited, so having multiple people evaluate the FMEA will allow for a more objective evaluation.

Examples and templates of items to be included in the FMEA evaluation format

When conducting an FMEA, it is common to use a dedicated format. Here we will introduce examples of items to include in the FMEA format and a template that can be downloaded for free.

Examples of items to be included in an FMEA

The FMEA format generally includes the following items:

| Items to be listed | overview | Example of description |

| subject | Describe the failure mode | Product A, manufacturing process B, worker C, etc. |

| Failure Mode | Describe the expected failure mode in detail | Damaged parts, system errors, work mistakes, etc. |

| Cause of failure | Describe in detail the cause of the failure mode | Design errors, material defects, incorrect operating procedures, etc. |

| Impact | Quantify and describe the magnitude of the impact if a failure mode occurs. | Outages, temporary suspension of production lines, etc. |

| Frequency of occurrence | Quantify and describe the frequency with which the failure mode occurs | high, moderate, low |

| Detection difficulty | Quantify and describe the difficulty of detecting the failure mode | Easy, medium, difficult |

| RPN | Enter a numerical value (risk priority) that is a product of the impact, frequency of occurrence, and difficulty of detection | RPN = Impact x Frequency x Difficulty of Detection |

Using this format, FMEA allows for systematic risk management.

FMEA template

You can download and use the FMEA template below.

Please use our original FMEA template and incorporate it into your work. For details, please download it from <FMEA template>.

FMEA implementation procedure

FMEA can be used to effectively conduct risk analysis by following the steps below.

- Creating an FMEA format

- Failure mode entry

- Enter the impact level

- Calculating RPN (Risk Priority Number)

- Planning and implementing improvement plans

From here, we will explain the basic procedure for conducting FMEA in five steps.

Step 1. Create an FMEA format

First, let's create a format for conducting an FMEA.

By clarifying the target of the FMEA and creating a format that includes the necessary items, it becomes easier to organize the information and manage it in subsequent steps.

Step 2. Enter the failure mode

For each product and process that is the subject of the FMEA, identify the anticipated risks and write down the failure modes and effects in the format.

Step 3. Enter the impact level

We quantitatively evaluate the risks caused by failure modes. We quantify them based on objective criteria for the three items of impact, frequency of occurrence, and difficulty of detection.

Step 4. Calculate the RPN (Risk Priority Number)

The Risk Priority Number (RPN) is calculated by quantifying and multiplying three factors: impact, frequency of occurrence, and difficulty of detection. It is an index that quantitatively indicates the priority of risk. Because RPN is an index that indicates the magnitude of risk, it indicates that measures should be considered in order of priority from the highest RPN.

Step 5. Formulate and implement an improvement plan

For failure modes with high RPN, we will develop an improvement plan to reduce their frequency of occurrence and limit their impact. After implementing the improvement measures, we will conduct FMEA again to confirm that the risk has been reduced.

Frequently Asked Questions about FMEA

Here are some frequently asked questions about FMEA.

What is FTA (Fault Tree Analysis)?

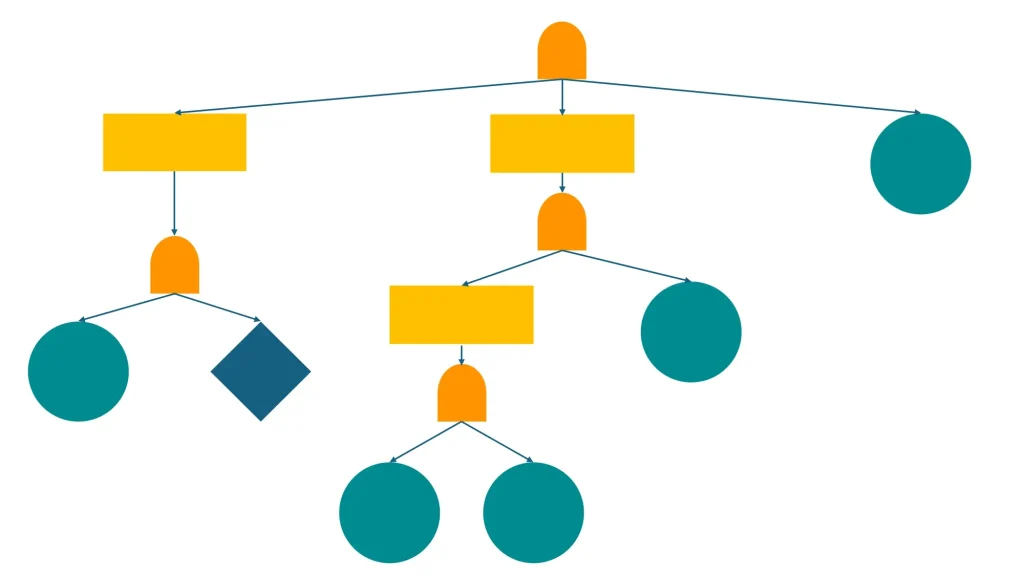

FTA (Fault Tree Analysis) is a method for visually analyzing the causes of failures in products and systems.

An event that should not occur, such as a product failure, is set as the top event, and the causes that lead to that top event are developed in a tree structure using logical symbols.

FTA allows you to visually analyze the causal relationships between problems and risks by creating a fault tree diagram (FT diagram).

What is DRBFM (Design Review Based on Failure Mode)?

DRBFM (Design Review Based on Failure Mode) is a design review that verifies the validity of the design based on the failure modes extracted by FMEA.

DRBFM brings together not only designers but also those involved in quality assurance and manufacturing to examine the validity of the design, identify problems, and identify improvement measures.

Efficient risk management using FMEA

In this article, we explained the overview of FMEA, its advantages and disadvantages, and the specific steps to implement it.

FMEA is a tool for identifying potential risks in product development and manufacturing processes and preventing them before they occur, but FMEA is merely one tool, and it must be used appropriately to maximize its effectiveness.

CIMTOPS' i-reporter is a tool that streamlines FMEA implementation and enables more accurate risk assessment. By utilizing a wide range of templates and analysis functions, even inexperienced personnel can smoothly implement FMEA.

Although i-reporter is a cloud-based system, it can also be used offline, allowing teams to collaborate regardless of location or time, even in places with unstable internet connections.

If you do not have personnel with FMEA expertise in-house, you can also use CIMTOPS' consulting services in addition to implementing i-reporter.

By using FMEA appropriately, you can potentially improve the quality of your products and services, increase customer satisfaction, and reduce costs. Why not use this article as a reference and try incorporating FMEA using i-reporter into your business?

This is the editorial department of the Field Document Research Institute!

This blog is operated by CIMTOPS Corporation., which develops and sells the field document electronic solution "i-Reporter."

We will be delivering industry information on a regular basis to help those of you working hard to promote digital transformation in the workplace, so please take a look!