A variety of reports are used in store operations. Typical examples include sales management sheets and accounting slips. Ideally, all reports should be designed to suit the company's business operations, but in reality...

How to create and write a work procedure manual [with a convenient free template]

table of contents

To gain the trust of customers in the manufacturing industry, it is necessary to provide a stable supply of high-quality products. However, as the number of different products handled increases, work procedures become unclear and tasks become dependent on individuals, often resulting in inconsistent quality.

Work procedure manuals solve these problems. In this article, we will explain the overview of work procedure manuals, the process for creating them, the benefits of using them, and points to keep in mind when using them. We will also introduce a system that streamlines the creation and management of work procedure manuals, so on-site managers and staff should definitely take note.

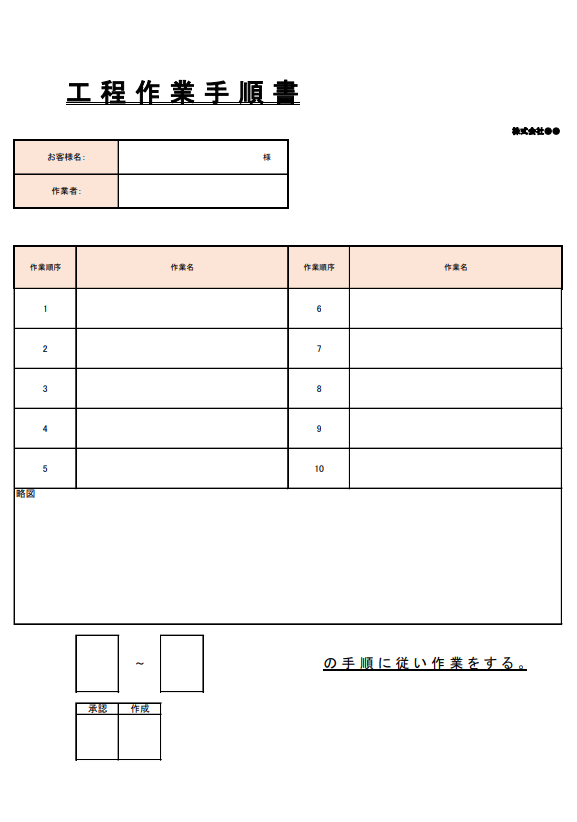

[Click here to download the process procedure manual for free]

<Process work procedure template>.

Basic knowledge of work procedures

Work procedure manuals are essential documents for standardizing work, improving operations, and ensuring safety on-site in the manufacturing industry. Here we will explain the overview and importance of work procedure manuals, as well as the main items to be included.

What is a work procedure manual?

A work procedure manual is a document that specifically describes the procedures for a job. Its role is to ensure that workers can carry out their work safely and accurately by following the contents of the procedure manual. To help the reader visualize the work content, the manual may contain not only text but also diagrams, photos, videos, etc. This document is sometimes called an SOP, an abbreviation for "Standard Operating Procedures."

Another term that is very similar to work procedures is "work manual." Work procedures and work manuals differ in the scope of work they cover. Specifically, work procedures focus on explaining procedures for specific tasks, while work manuals are documents that show the overall flow of your company's work. If you want to communicate the detailed rules for each task to workers, you should create a work procedure manual; if you want to convey the overall picture and standards of your company's work, you should create a manual.

The importance of work procedures and the purpose of creating them

Work procedure manuals are essential for the smooth progress of on-site work. Ideally, even if workers change, the quality of work should remain the same as long as the manual is followed. By preparing work procedure manuals that are easy for anyone to understand, it becomes easier to smoothly hand over work. Work procedure manuals are also important for eliminating waste in work as much as possible and aiming for work efficiency.

Work procedure manual structure and main items

There is no set format for the structure or items to be included in a work procedure manual. It is important to include information appropriate to the work content and organization. Below we will introduce the items that are typically included in a work procedure manual.

<Major items to be included in the work procedure manual>

- Worker

- Purpose of the work

- What is needed for the work (materials, tools, space, facilities, systems, etc.)

- Work procedures (points, precautions, checklists, etc.)

Flow of creating a work procedure manual

Next, we will explain the flow of creating work procedures in four steps. By following these steps, you will be able to create work procedures efficiently.

Step 1: Identify work information

First, to gain a comprehensive understanding of the entire process, break down the work for which you are creating a procedure manual into unit tasks. A unit task is a process that would look unnatural if not performed continuously by one worker. For example, when creating a procedure manual for "desk manufacturing work," first identify the broad tasks (component tasks) such as "assembly" and "painting." Then, break down the component tasks into unit tasks such as "assembling the tabletop," "joining the tabletop and legs," "painting the tabletop," and "drying."

The ideal first step is to create a list of all work processes so that they can be understood. The information identified here will serve as the basis for determining the content and structure of the work procedure manual. Once you have completed collecting information, have the person actually doing the work check it to make sure it matches the actual situation. In cases where multiple people are working on the project, having all members involved check it will make it easier to prevent omissions and oversights.

Step 2: Decide the structure of the work procedure manual

The next step is to consider the overall structure of the work procedure manual. This involves rearranging the work information identified earlier into appropriate procedures and deciding which items to include in the work procedure manual. When considering work procedures, it is a good idea to consider whether they can be further simplified, whether there are any unnecessary movements, and whether the postures or work content are unnatural.

Step 3: Add an explanation of the work content for each task

The next step is to write an explanation of the actual work to complete the work procedure manual. It is important to avoid using difficult terms and to use concise expressions so that interpretations do not differ from reader to reader. If it is difficult to put into words, it is also a good idea to use diagrams, photos, videos, etc. Additionally, to reduce errors in the work, it is effective to clearly state points for self-checking after completion.

Step 4: Receive feedback from the employees involved and make revisions

Finally, once the work procedure manual is complete, put it into operation and check for any areas for improvement. To create a high-quality work procedure manual, it is important not to complete it once and then leave it at that, but to revise and update it as needed based on feedback from workers. Also, there may be cases where the introduction of new equipment or the emergence of new products requires revisions to the contents.

Benefits and points to note when creating a work procedure manual

What are the benefits of creating a work procedure manual for the workplace? Here we will introduce them along with some points to keep in mind.

Benefits of creating a work procedure manual

Stabilization and improvement of business quality can be expected

Preparing work procedures reduces the number of cases where staff work in unique or incorrect ways, which helps prevent mistakes. Another benefit is that the quality of work is stabilized and improved, which leads to increased trust from customers.

This leads to reduced work time

With work procedures, employees will no longer be confused about what to do next, which is expected to reduce work time and improve productivity. It also leads to more efficient progress management for on-site managers, making it easier to forecast and schedule work.

It becomes easier to prevent work from becoming dependent on individuals.

Another benefit of utilizing work procedures is that they allow both new and experienced employees to achieve a certain level of quality, preventing work from becoming dependent on individual skills. Also, using work procedures to train new and inexperienced employees reduces the effort required for training, making it easier to make them a valuable asset with fewer man-hours.

Points to note when creating a work procedure manual

It may be difficult to generate new ideas

When work procedures are prepared, the person in charge can perform the work with a certain level of quality simply by following them. In other words, there is less need to think or act in ways that are not described in the procedures.

Therefore, if you assume that work procedures are perfect, there is a risk that it will become difficult for employees to identify issues from their own perspectives or generate ideas. Although it is essential that employees follow the work procedures, it is important to tell them to provide feedback immediately if they find any areas for improvement.

Spending too much time creating procedures

When creating work procedures, there are cases where too much time is spent trying to prepare a high-quality manual. It is difficult to create a perfect procedure manual from the beginning, so it is best to include the minimum amount of information necessary to ensure the smooth execution of work and safety, and then gradually refine it as you use it.

Key points for creating and using work procedures

To maximize the effectiveness of work procedures, what should you pay attention to when creating and using them? Here are two points to consider.

Make the structure and content easy to understand at a glance

Work procedure manuals must be accurate and easy to understand for all personnel. To achieve this, it is important to use illustrations, photos, videos, etc. to create a structure and content that is easy to understand at a glance. Also, by keeping the 5W1H in mind when writing, you can create a procedure manual that is easy to understand even for people performing the work for the first time.

Introducing a cloud-based management system

To properly manage work procedures, it is best to reduce the time and effort required for checking and correcting them. Because paper-based management can easily lead to a large amount of work required for checking and correcting, it is recommended to introduce a cloud-based management system.

Recommended systems for streamlining work procedure management

If you are having trouble efficiently creating and managing work procedures, we recommend introducing "i-Reporter" provided by CIMTOPS Corporation. i-Reporter is a system for digitizing on-site reports, and is a service that allows you to replace your current paper or Excel-based work procedures with electronic reports. When migrating, you can import the familiar work procedure format directly into i-Reporter, which has the advantage of allowing on-site personnel to start using it quickly and without any confusion.

Another advantage of i-Reporter is that it can manage work procedures on the cloud. Even if an omission or an area for improvement is found in a work procedure, the data on the cloud server can be updated and immediately shared with the site. If work procedures were kept on paper, the documents would have to be re-created, printed out, and distributed again.

In addition, by devising a system, it is possible to reduce work errors, such as by providing checkboxes in work procedures so that you cannot move on to the next task until all the boxes are filled in. We will propose appropriate solutions based on your company's work environment and challenges, so please feel free to contact us for a consultation.

[Reference]i-Reporter, an electronic system for on-site reports

Utilizing work procedures to streamline on-site operations

This time, we provided an overview of work procedure manuals in the manufacturing industry, the flow for creating them, their benefits, and key points to keep in mind when using them. Although creating work procedure manuals requires a certain amount of effort and cost, preparing them is an important document that helps improve work efficiency and prevent work from becoming dependent on individual skills. When creating work procedure manuals, try to use language that can be understood by anyone, regardless of the reader's skill level, and adjust the content based on feedback from the workplace.

This is the editorial department of the Field Document Research Institute!

This blog is operated by CIMTOPS Corporation., which develops and sells the field document electronic solution "i-Reporter."

We will be delivering industry information on a regular basis to help those of you working hard to promote digital transformation in the workplace, so please take a look!