The world is gradually becoming digitalized, and the adoption rate of DX in highly productive high-tech factories is extremely high. However, in the process management of small and medium-sized enterprises, the term "digital..." is often heard.

Is it difficult to change the rules of on-site digital transformation in the manufacturing industry?

Introduction

table of contents

My name is Kitagawa, and I am the representative director of K-crew Co., Ltd., and I have been asked to contribute to the ``Field Document Research Institute.''

This series is Aimed at team leaders working on on-site DX or those involved in proposing improvements using IT tools is.

Based on the author Kitagawa's experience of business improvement cases and on-site problems in production sites, he will provide insights and hints for promoting DX.

Reading this article will give you the following benefits:

1. Understand the basic concepts behind on-site improvements

2. Understand on-site improvement methods that don't rely on IT tools

3. Understand the importance of understanding the true nature of business objectives

"On-site improvement depends on the ability to recognize the essence of the problem."

In the first session, we will talk about the theme, "On-site improvement depends on the ability to recognize the essence of the problem."

Even if there is one person who can notice an issue on-site, simply communicating the issue and proposed solution to the person in charge on-site will rarely lead to improvement activities across the entire company.

How can we create a movement that involves individual departments and the entire company?

Is it "difficult" to change the rules?

Whether you use convenient IT tools or not, it is possible to improve efficiency through business operations.

Business improvement simply means that work can be "changed" in a "good direction," but this is something that many people on the front lines struggle with.

All I need to do is "do the same thing (or improve the quality) in a shorter amount of time without compromising the quality of the work," but I seem to be thinking about too many things.

This is an example that I experienced at a client's company, but I think similar things happen in other companies too.

I will briefly explain the work, and together we can think about what the problems were and how we solved them.

[Transmission of production information]

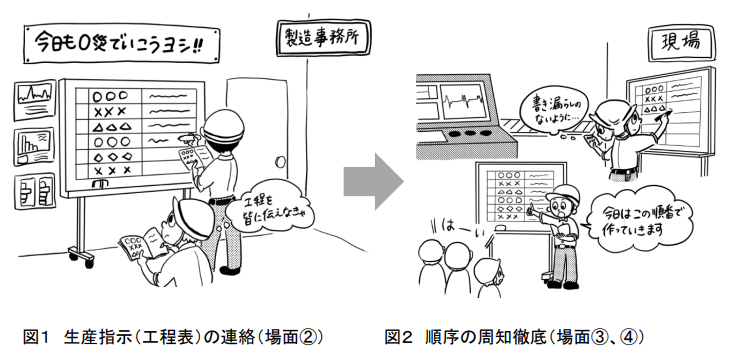

① Mr. A from the Production Control Department makes a production plan for this month, creates a schedule and distributes it to each site.

② After receiving the schedule, Section Chief B of the Manufacturing Department checks whether production can be carried out as planned. If there are no problems, he writes the production plan on the schedule on a whiteboard in the Manufacturing Office (which also has a break room and is a space for sharing information with his subordinates) and shares the production plan with his section.

③ Worker C, who belongs to the section, looks at the schedule in the control room and checks the process for the product he is in charge of.

④ Worker Foreman C (from the top of the hierarchy, it is section manager - section chief B - workman C - worker mob) takes notes on the schedule in the control room and writes the schedule on a whiteboard near the work site so that the information can be shared with the on-site workers and work assistants.

⑤ Now that we can share the production items for the day or this week with everyone, production and switching of production items will be smoother.

Scenes like this are common (Japanese manufacturing sites are extremely serious).

If you go back about 20 years, this kind of situation was actually quite common.

Now here's the problem.

In an age when convenient IT tools like i-Reporter did not exist, think about how to thoroughly inform production plans down to the lowest level workers (this is the kind of improvement that would have been made 20 years ago).

You can use the copy machines and fax machines that you have been using for a long time.

[One answer]

There are many ways to improve this, so there is no one right answer.

The characters are Mr. A, who created the schedule, Section Chief B, who received the schedule, Foreman C, who tries to share the information from Section Chief B with the production site, and many other on-site workers.

Each person in charge repeats the process of passing on the information they receive to the next process, as it is information that needs to be communicated.

This process simply involves changing the form of (part of) the information received and transmitting it (this method was the norm in the past).

The purpose of this work is to share and disseminate important information throughout the manufacturing department.

The goal can be achieved by faithfully carrying out the previous and subsequent steps, which are "I receive the information in the previous step and pass it on to the next step."

But I wonder if this kind of game of telephone is really good, and if there is a better way.

Simply conveying accurate information in a straightforward manner is not a very interesting game, but what can be done to make this game of telephone as fast as possible?

The answer is simple!

The fastest way to convey information is for the first person to convey the answer (information) to the last person.

As a game of telephone, it's not much fun at all.

So, if we replace this with a schedule problem, it looks like this:

The "progress chart" you receive first will usually be A4 or A3 size, but you can simply get two enlarged A0 copies and post them in the management office and the work area on site.

Currently, it would be possible to simply display the Excel file on a large monitor on-site, but this time we are unable to do so due to constraints.

The important thing here is that the people who were playing the "game of telephone" themselves realized this "waste" and felt that they needed to improve it.

Rather than simply providing solutions using convenient tools, it is extremely important to create an organization where everyone is aware of the "real issues" and calls for improvements are made not only from the workplace but from various departments as well.

If we can create a forum like this where people can "raise their voices to solve problems," then we can say that we have achieved about 80% improvement.

There are probably many ways to go about this, but how will you (your company) solve these kinds of problems?

Next time, I would like to talk about the kind of ``ties'' that are not easily changed.

現場帳票研究所の編集部です!

当ブログは現場帳票電子化ソリューション「i-Reporter」の開発・販売を行う株式会社シムトップスが運営しております。

現場DXの推進に奮闘する皆様のお役に立てるよう、業界情報を定期的に配信致しますので、ぜひ御覧ください!