Preventing work mistakes on-site

If you are looking to improve business efficiency!

share の現場帳票システム

table of contents

This time, we will be looking at industries such as manufacturing, logistics, and retail.

The problems faced by field workers

We will introduce you to a solution.

If you have any problems with your work,

Please feel free to use this as a reference.

POINT 1Problems faced during on-site work

In the manufacturing industry, "reducing paper" such as forms is an issue

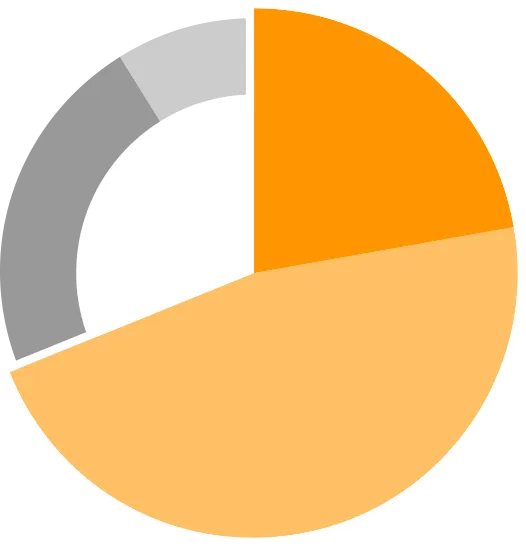

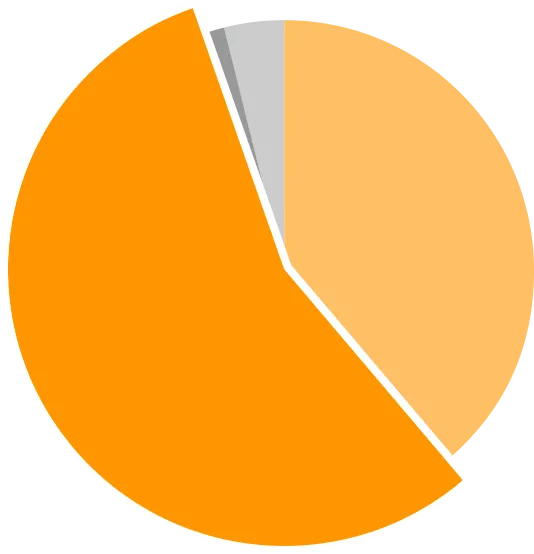

In a 2023 survey of 103 managers and executives of major manufacturing companies, 70% of companies responded that they were making progress in efforts to reduce paper use. However, the remaining 30% responded that they were not making progress, indicating that challenges remain in the industry.

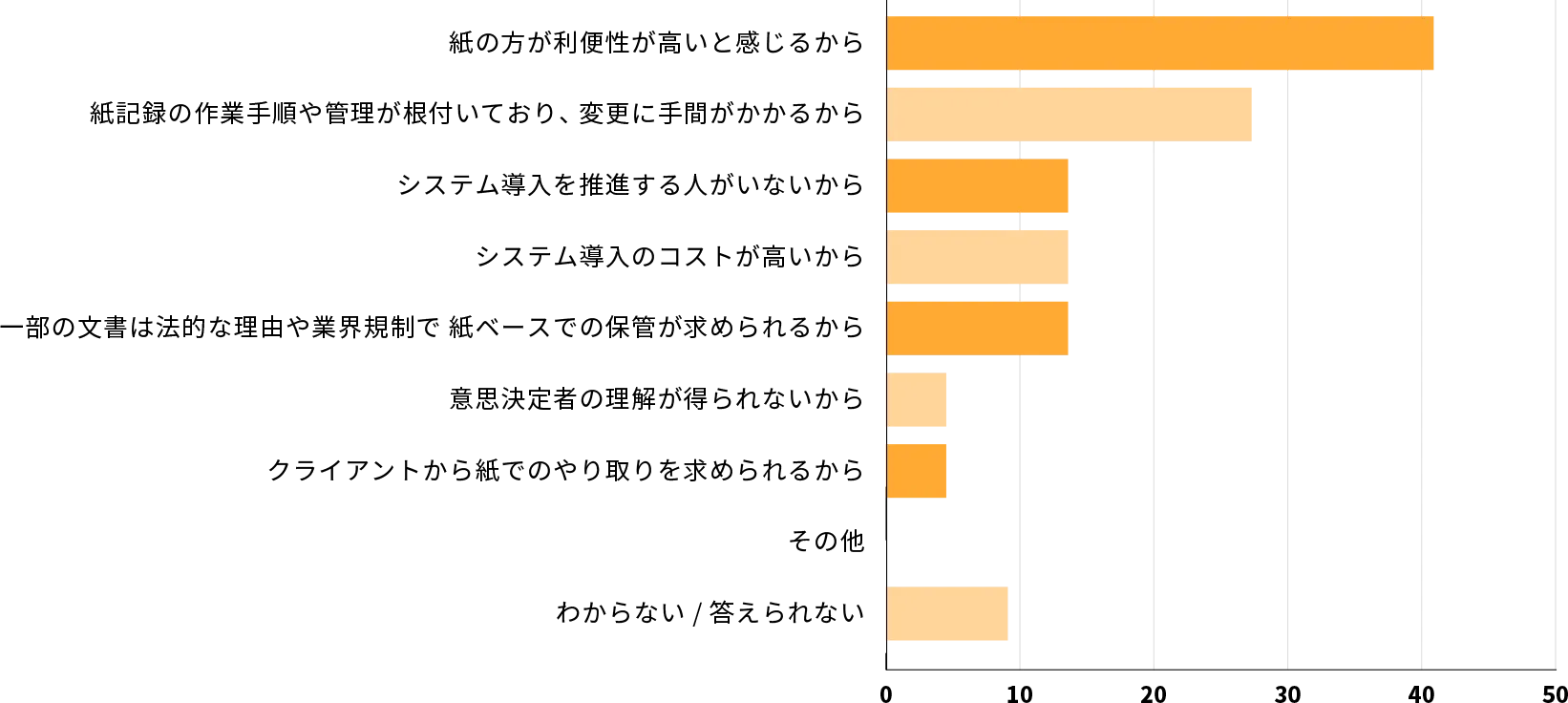

Reasons given for the lack of progress included "paper is more convenient" and "it's too much work to make the change."

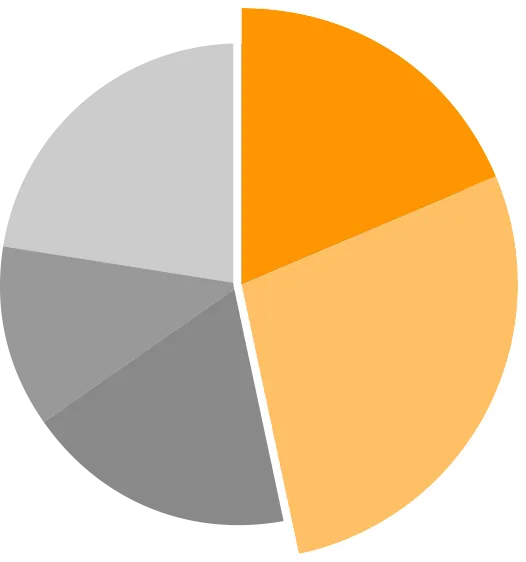

Q1. Is your company making progress in reducing paper usage?

● 22.3% are well advanced

● 46.6% Somewhat advanced

● 22.3% Not much progress

● 8.7% have not progressed at all

● 0.0% I don't know/can't answer

Approximately 70% of companies responded that they are making progress in their efforts to reduce paper use.

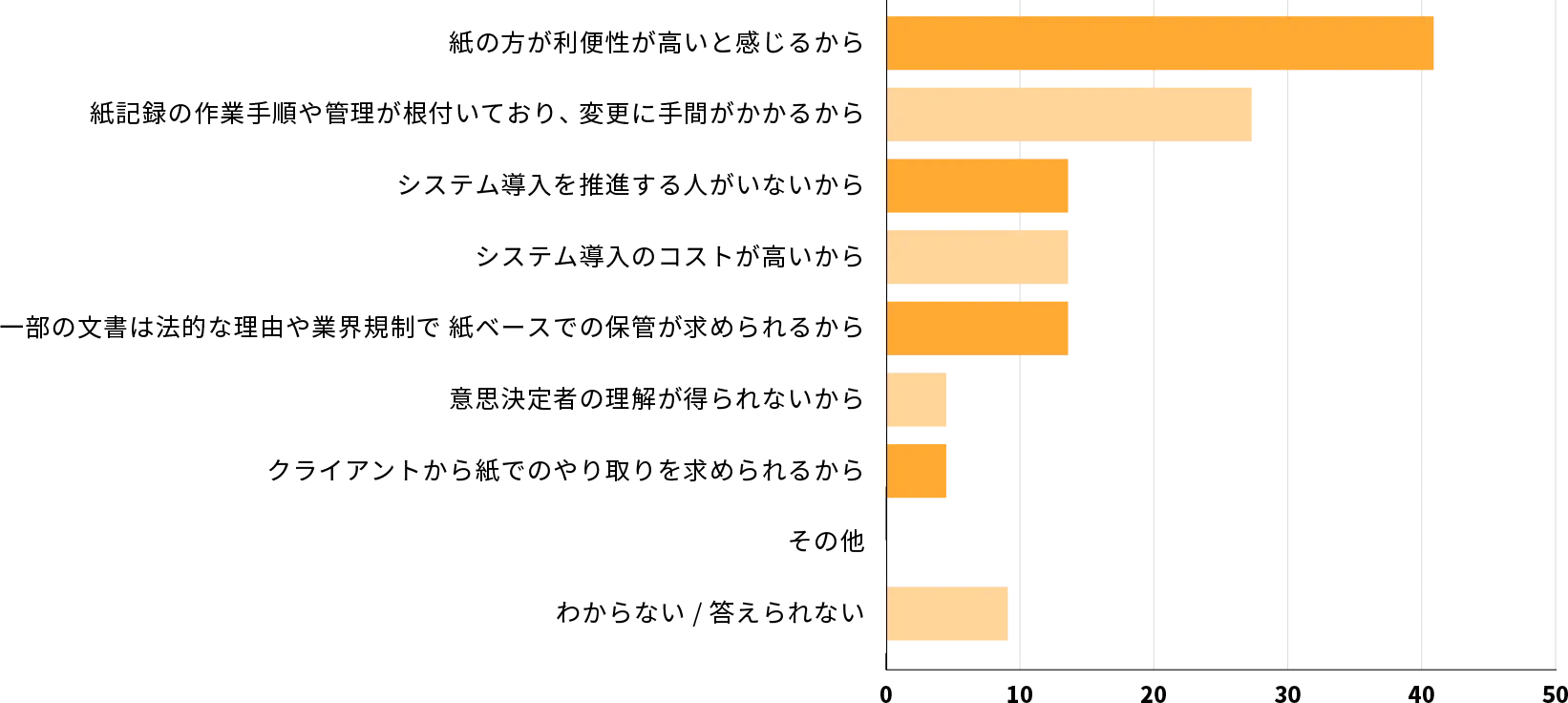

Q2. This question is for those who answered "Not much progress" or "Not progress at all" in Q1.

Please explain why efforts to reduce paper use are not progressing. (Multiple answers)

The logistics industry faces the "2024 problem" (restrictions on working hours)

Starting in 2024, truck drivers will be limited to a 960-hour overtime work limit and revised improvement standards will be implemented, resulting in shorter working hours.

As a result, mail delivery capacity has declined, and a shortage of truck drivers has become an issue. Improving the productivity of each employee is an urgent task, and increasing work efficiency and reducing work errors are becoming increasingly important in the field.

However, in a survey conducted in 2023, approximately half of the 107 on-site managers and staff in the warehouse, logistics, and manufacturing industries responded that they were not taking any measures to prepare for the 2024 problem.

Q3. Is your company making progress in addressing the 2024 problem?

● 18.7% are well advanced

● 28.0% Somewhat advanced

● 18.7% Not much progress

● 12.1% have not progressed at all

● 22.4% I don't know/can't answer

Regarding efforts to prepare for the 2024 problem, approximately half of the respondents answered that they are "making progress."

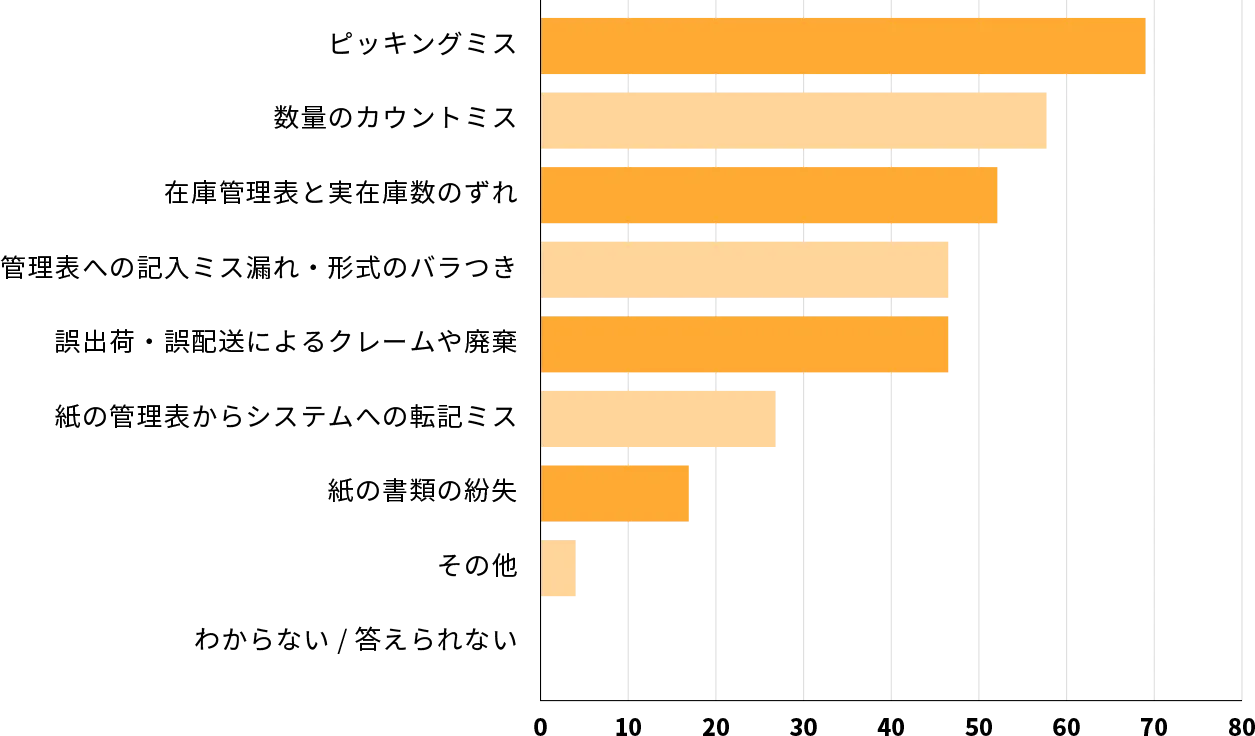

Additionally, many people cited picking and counting as tasks where mistakes are most likely to occur. To solve the 2024 problem, it is important to improve the efficiency of these tasks and reduce mistakes.

Q4. What mistakes occur in the warehouse and logistics operations at your company? (Multiple answers allowed)

The number one mistake that occurs in warehouse and logistics operations is "picking errors."

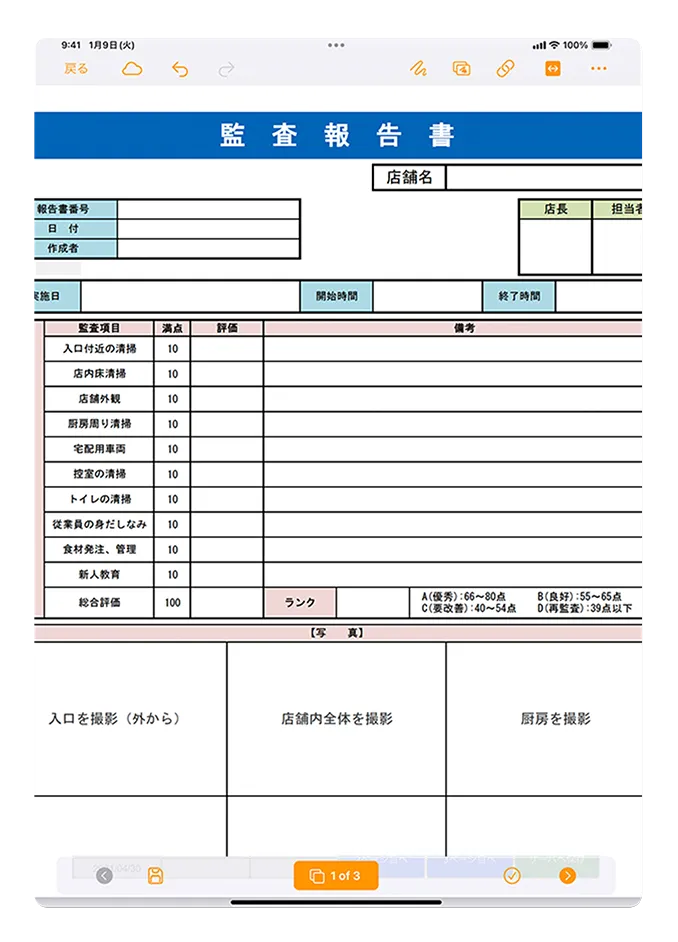

The large number of analog operations is an issue in the retail and food service industries

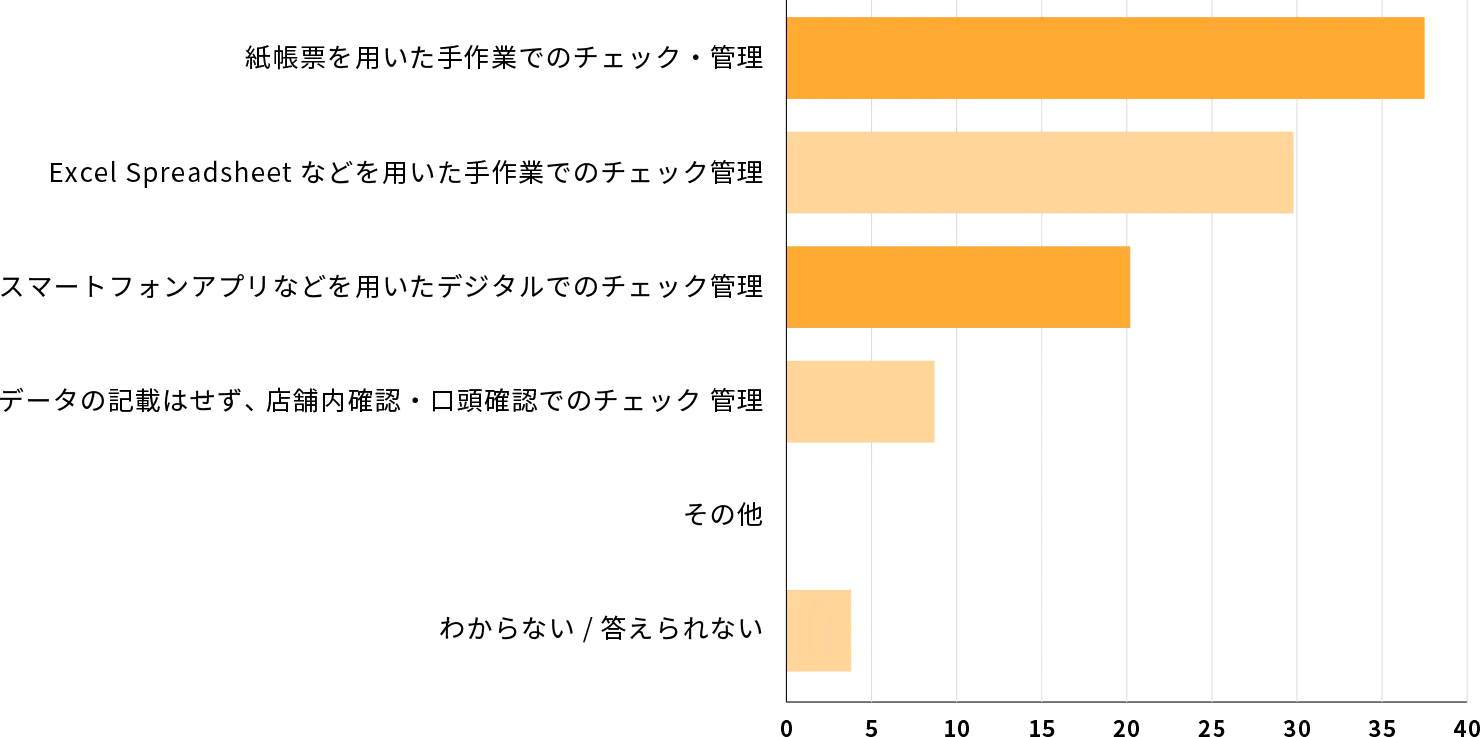

A survey conducted in 2024 among store managers and area managers in the retail and food service industries found that approximately 40% currently perform QSC checks using paper forms.

In addition, after the implementation, 40% of stores still store documents in paper files, indicating that many stores still conduct business in an analog manner.

Q5. Please tell us the main QSC check methods used at your workplace.

The main QSC check methods are "Manual checking and management using paper forms" was the most common at 37.5%. and

It has become.

Q6. What is the main method for managing and saving QSC check results?

● 39.4% stored in paper files

● 55.8% Stored in digital format such as PC or cloud

● 1.0% Other

● 3.8% Don't know/can't answer

"Saving in a digital format such as on a PC or in the cloud" was the most popular answer at 55.8%.

\ Input will take 30 seconds. /

For inquiries about implementing on-site reports, please click hereIssues resolved by introducing on-site reports

- What on-site reports can do

- ① Prevents errors and falsification of documents

- ② Managers can check reports in real time

- 3. Paperless system reduces management costs

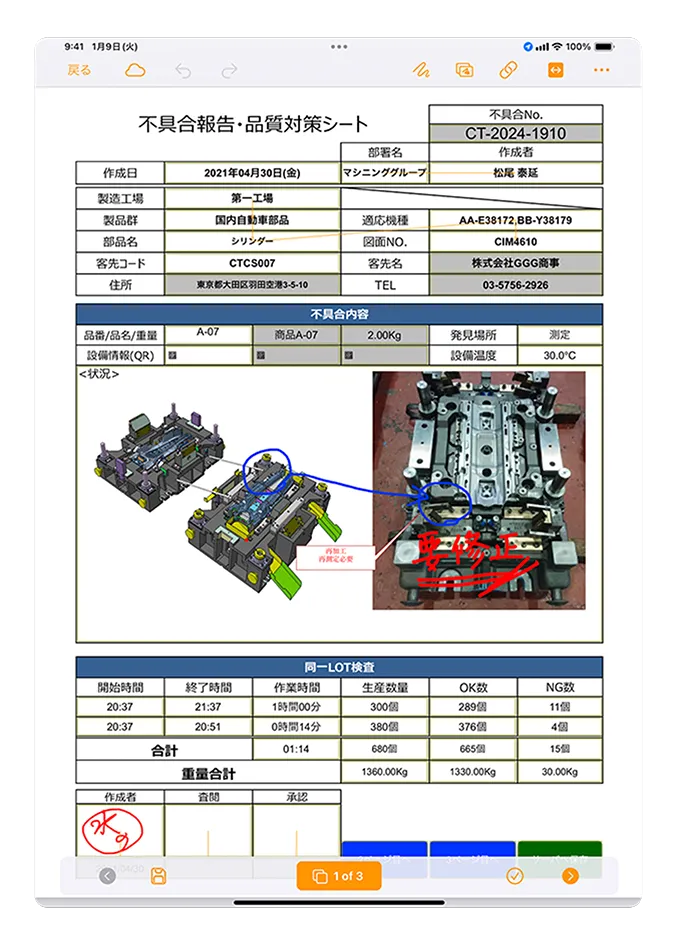

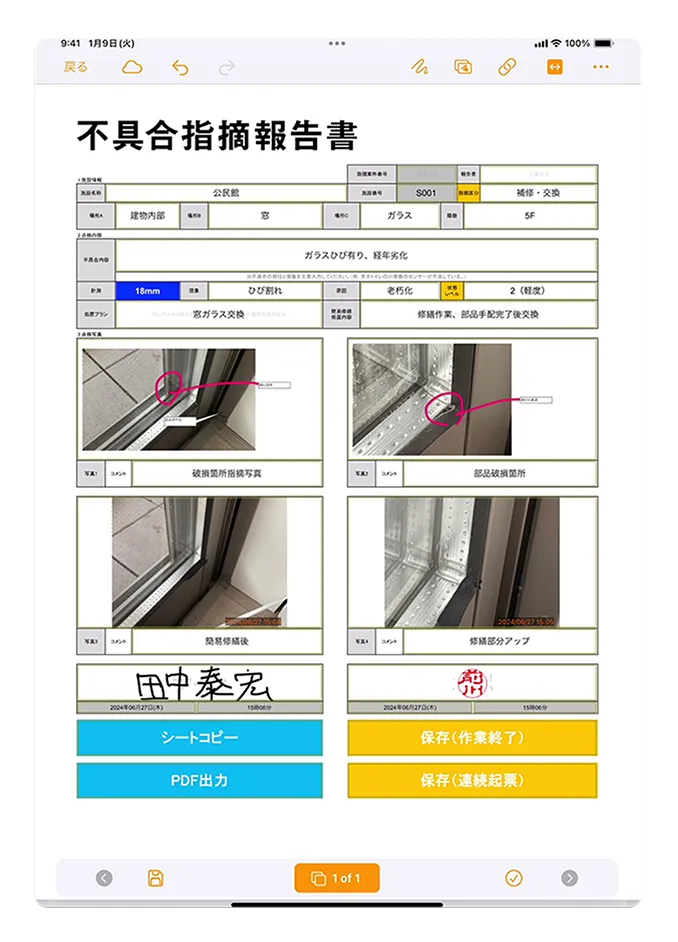

These industry problems can be reduced by introducing on-site forms. By digitizing forms that were previously filled out on paper, a history of who filled out the form, when, and what information was entered is kept. After the form is filled out, the person in charge can immediately check the content, making it possible to grasp the situation on-site in real time.

In addition, digitizing documents also reduces management costs, eliminating issues such as loss or spoilage of stored documents.

POINT2Digitizing documents is important for solving problems

Concerns when introducing a field report system

When introducing a field report system, many companies are concerned that it will be difficult for the system to take root in the field.

A survey conducted in 2023 among manufacturing companies revealed that nearly 70% of companies that have not yet made progress in introducing on-site reports feel that the hurdles to implementation are high.

Therefore, when implementing a tool, it is important to choose one that can be used smoothly by on-site personnel. Also, introducing a tool that can be integrated with existing tools will broaden the scope of its use.

Q7. This question is for those who answered "Not much progress" or "Not progress at all" in Q1.

Please explain why efforts to reduce paper use are not progressing. (Multiple answers)

Benefits of introducing a field report system

The advantage of introducing a site report system is that it streamlines the creation and storage of reports, reducing on-site work hours and improving employee productivity.

1Thesituation on-site is conveyed accurately

Various input support functions, such as taking photographs, recording audio, reading barcodes, linking to master data, judging thresholds, and specifying the order of work, allow you to collect information about the situation on site accurately and efficiently.

2Real-time data sharing and utilization

The report contents are instantly saved in a database, making it possible to share on-site conditions with other departments and locations in real time.

3.Significantly reduce the burden of collecting, compiling, analyzing, and managing data after reporting

After recording, on-site reports can be output in a batch on a weekly or monthly basis, photo data that is difficult to organize can be automatically renamed, and report data can be automatically sorted, significantly reducing the amount of post-processing work required after filling out reports.

\ Input will take 30 seconds. /

For inquiries about implementing on-site reports, please click herePOINT3Points to consider when choosing a field report system

It is important to have a wide range of business operations and a wide range of tools that can be linked together

When introducing a site report system, it is important to ensure that it can be applied to all operations currently operated using paper reports. If only certain operations can be digitized, it will ultimately be necessary to introduce multiple site report systems, which will cause inconvenience to users and result in the dispersion of site information. To do this, it is essential to ensure that the system not only has a wide range of input functions, but also that it can be linked to existing in-house systems. Linking with core systems, progress management systems, AI, etc. will have a significant effect on the system's penetration within the company.

i-Reporter not only has over 100 input support functions, but also allows for flexible integration with other systems. It offers a variety of integration methods and destinations, including CSV output, database reference, WebAPI, and no-code integration using i-Repo Link (databases, kintone, other business systems).

It must be easy and intuitive for field workers and managers to use.

When on-site reports are systemized, there are cases where the screen changes significantly from the report layout that was previously used. A common example is changing from a report layout to a layout optimized for the web. In this case, since the input method for workers is different from before, it is essential to promote understanding and education on-site in order to get the system to take root. Also, some types of reports are not suited to web layouts in the first place, so it is essential to coordinate with on-site workers.

i-Reporter can digitize existing on-site report layouts as they are, allowing on-site workers to continue entering data intuitively as before.

\ Input will take 30 seconds. /

Click here to download i-Reporter materialsIs it more inconvenient than paper forms?

When introducing a field report system, it is essential to check whether there are any inconveniences compared to paper-based operations. For example, if the work location is in an environment where there is no or poor reception (such as a field site, a customer's office, or underground), the system may become unusable. If this happens, you will have no choice but to use paper field reports partially, which will require post-processing such as system transcription and report creation after returning to the office. i-Reporter can also be used in offline environments, so you can carry out recording work in the same way as paper field reports, regardless of the network environment.

POINT4Questions about the on-site report system "i-Reporter"

Q. What is the process for implementation?

First, check whether your company's issues can be resolved through seminars or individual consultations. After that, try using i-Reporter for yourself with a free trial.

After the trial, if you are considering implementing the system, we will provide you with a quote and information on the contract.

Q. Can I use it overseas?

i-Reporter is available in Japanese, English, and Chinese (Simplified and Traditional). In addition, because report layouts are created in Excel, they can be created and entered in various languages, including Thai and Vietnamese. It is used by approximately 300 companies and 7,500 users (as of September 2023) in 16 countries, including Southeast Asian countries, China, Taiwan, Korea, India, the Middle East, the United States, and Mexico. We have agents in each country who can provide proposals and technical support in the local language. Please contact CIMTOPS for details.

Q. Can I work in places where there is no radio signal?

It can be used even when there is no signal. Since i-Reporter is a native app, if you download the necessary reports, you can use it even without a network connection.