Case Study: Mocras Co., Ltd.

Mocras Co., Ltd.

How i-Reporter was used to reduce the time required to analyze work by client and product from 15 days to 2-3 minutes

Kaizen effect

It takes about 15 days in total to output the monthly work hours by manufacturer and product, transcribe the data, and compile the data.

By simply inputting data into i-Reporter, data could be easily compiled, and analysis was shortened from 15 days to 2-3 minutes.

It takes time to collect and analyze data, and we can only grasp the work hours for some manufacturers and products.

The trend of average work time was visualized for each manufacturer, product, and process.

作業者が作業時間を切り上げて記入するなどの問題や入力ミスが発生

By scanning the QR code on each instruction sheet when starting work, the start time of work can be automatically recorded.

-

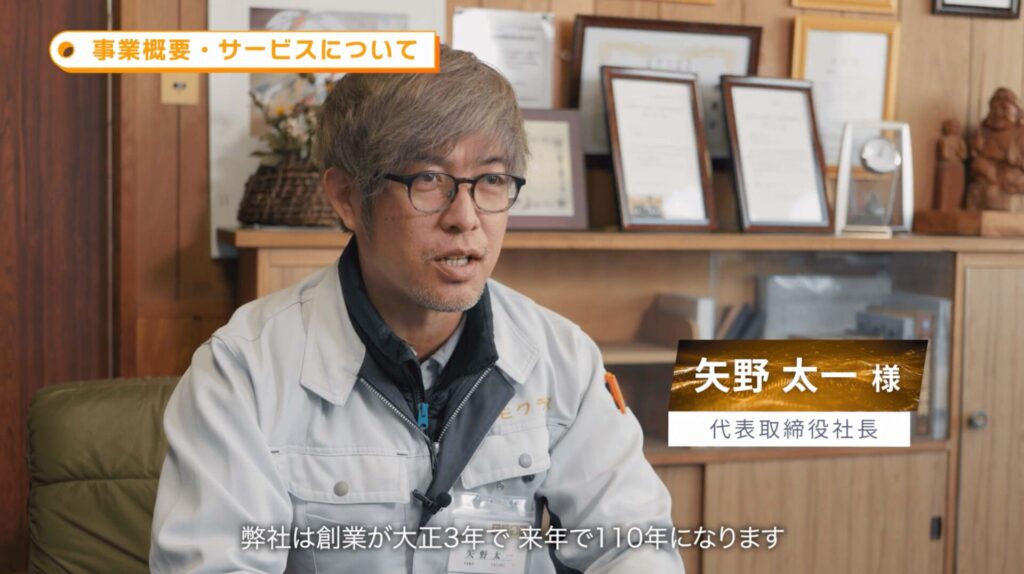

President and CEO Taichi Yano

-

Responsible for creating reports Ms. Masuda Mami

-

Factory site team leader (Team 2) Mr. Kenji Kunisige

-

Factory site team leader (Team 1) Yusuke Kondo

-

Responsible for data analysis Mr. Akifumi Yamaguchi

We manufacture products based on drawings for building material manufacturers.

Mr. Yano: Mocras Co., Ltd. is a manufacturer of residential interior building materials. Originally, the company started out selling lumber, but now our main business is building material processing, with building material manufacturers as clients. Now, we make products based on drawings sent to us by building material manufacturers.

The deciding factor for introducing i-Reporter was that we felt it was an issue with the huge amount of data input and compilation work we had to do every day, and we decided to introduce it to eliminate that issue. After introducing it, we have been successful in shortening the data compilation work, which used to take a total of about 15 days, to just 2-3 minutes through data input, compilation work, and data automation.

Traditional paper-based management has issues

-Please tell us in detail what tasks and processes you encountered and what issues you faced.

Mr. Yano: Our company processes and ships products for a variety of customers.

Although they wanted to analyze the productivity of products for each customer in order to improve efficiency and quality, they felt there were issues with the old-fashioned paper-based management.

Even if you take the time to analyze Only certain manufacturers and product-specific work hours can be tracked It was. Also, Even in order to grasp the data, it takes about two weeks just to transfer it to Excel and tally it up, and the amount of input work is so huge that it is impossible to even get started on data input. That was the current situation.

Furthermore, regarding the work hours written on paper, There were also problems with data input rules not being followed and input errors occurring, resulting in low accuracy of the data that had been collected.

First, break away from your intuitive understanding of the current situation

-What did you decide to work on to solve the background and issues?

Mr. Masuda, Mr. Kunishige, and Mr. Kondo:

To improve productivity, Quantitative understanding of issues I decided to work on this.

At that time, the work was done based on the team leader's intuitive understanding of the situation. Grasp the current situation quantitatively in real time I thought it was necessary to do this.

I thought that if we could achieve the following three things, we could solve the problem.

① Highly accurate input of work time (for each process)

② Automatic calculation of entered data

③ Automatic analysis of input data (e.g., work time trends for one product)

Previously, we created paper documents called "instructions" in Excel every day to give production instructions to each process and distributed them to the site.

So K-crew Co., Ltd., a distributor of i-Reporter, has embedded a QR code into this "instruction sheet" to provide an easy way to obtain accurate work results with reduced burden on workers. We received the following suggestion.

Initially, we considered using a PC to input results, using Excel, VBA, and a scanner, but since it would be impossible to install a PC at every process, we decided to go with the cost-effective and mobile combination of iPad and i-Reporter.

Automatically record work hours using QR code printing

During the initial trial, only four or five iPads were introduced, but the president's policy of one iPad per person led to even greater changes after the introduction. I think so.

Specifically, production instructions are written in Excel and instructions with QR codes that can be used to create i-Reporter reports are distributed to the site. When workers start work, they can automatically record the start time of the work by scanning the QR code on each instruction sheet.

Also, Since the time is recorded not only at the start of work but also at the end, it is possible to measure work time accurately and visibly confirm the reduction in work time. We have also realized that visualizing these work times can be an effective indicator for our efforts to improve work efficiency within the company.

Wide range of uses including equipment and measuring device inspections, patrols, etc.

-Where and how do you use i-Reporter?

Field workers use it in the following four situations:

① Entering work hours

We designed the form so that when multiple people are working at the same time, actual results can be entered into the form without the need for multiple people to input data.

In addition, workpieces with different part numbers but the same shape (different patterns, colors, etc.) are usually processed at the same time, and we have devised a form that makes this input work easy.

[Work analysis time reduced from 15 days to 2-3 minutes]

1) CSV output in the manager

2) Copy this file to the specified folder.

3) Start the macro and click the following three buttons to complete the calculation.

- Button to create blank sheets for posting each worker's performance

・Attendance information (CSV data from time cards) import button

・Import button for the work time data (CSV data downloaded in (1))

②Inspection of facilities

Utilizing the system to eliminate the need for stamping and paperless inspection sheets for approximately 70 pieces of equipment

③Inspection of measuring equipment

Utilizing the system to eliminate the need for stamping and paperless inspection sheets for approximately 40 pieces of testing equipment

④ 5S Patrol

Patrol the site and highlight the key points of your own management area. Point out issues and use the results to improve 5S activities.

Automatic calculation of work time using i-Reporter and VBA

-Please tell us if there are any examples of how data output from i-Reporter is being used.

Mr. Yamaguchi:

当初からの目的であった、作業時間を自動集計できるVBAのシステム(Microsoft Officeに含まれるアプリケーションソフトの拡張機能)を作成しました。

Until now, I had to open the CSV data output from i-Reporter in Excel and manually calculate the data. By automatically creating individual work sheets for on-site workers from the master management and recording the information accumulated in i-Reporter, it becomes possible to tally up the work hours for each manufacturer's product. It has become.

We also graph the data for analysis purposes. Visualization of trends in average work time by manufacturer, product, and process We are doing the following.

In addition, it is now possible to use simple macros and Excel functions to check the submission of inspection records, etc.

By visualizing records, Until now, the amount of work required for each product had only been in the mind of the team leader in charge of the site. Now, the amount of work required for each product can be visualized. It is also very helpful for that.

Analysis time reduced from 15 days to 2-3 minutes

-How effective has the introduction of i-Reporter been?

Mr. Yamaguchi:

The amount of work required to compile data has been dramatically reduced, and the accuracy of records has improved.

Before the introduction, it took about 15 days in total to output the monthly work hours by manufacturer and product, transcribe the data, and compile the data, which made it difficult to enter the data. However, after the introduction, it has become possible to easily compile the data by simply entering the details.

In addition, by introducing i-Reporter and creating a system around QR codes and VBA, It is possible to compile data on all products from all manufacturers, not just major manufacturers It has become.

i-Reporter has other benefits besides recording. It also serves as a communication tool..

Now, workers use iPads on a daily basis, exchanging messages such as, "I don't understand this part."

Achieving greater customer satisfaction with i-Reporter

-Please let us know if there are any improvements you would like to undertake or activities you would like to undertake in the future.

Mr. Yano:

In the future Proposals for processing and manufacturing methods that will please our customers I would like to aim for that.

in particular, By utilizing i-Reporter and reviewing the material ordering process, we will solve problems such as communication delays due to the distance of the office, miscommunication and mishearing on the phone, and lengthy approval flows when processing errors occur, thereby achieving even greater customer satisfaction. We will continue to do so.

Company Profile

Mocras Co., Ltd.

- Established:

- (Established) 1914

- Headquarters:

- 2112-35 Takuma, Takuma-cho, Mitoyo City, Kagawa Prefecture, 769-1101

- Business Description:

- Mokurasu is a company located in Mitoyo City, Kagawa Prefecture that specializes in residential storage and interior materials. It has been in the wood processing business for over 100 years.

The above reviews are quoted from ITreview.(https://www.itreview.jp/products/i-reporter/reviews)

※ITreview is a real-name, company-verified review platform featuring authentic feedback from professionals on the front lines.