Case study: Kyushu Yanagawa Seiki Co., Ltd.

Kyushu Yanagawa Seiki Co., Ltd.

A case study of real-time management of a 200-meter painting line and accelerating the improvement cycle

Kaizen effect

Manual recording was tedious, and obtaining information required visiting the site and checking daily reports.

Information can now be easily entered on tablets and PCs, and is immediately shared with other departments.

It was difficult to grasp the parts coming from the previous process in advance, which affected work preparation.

Immediately register each part, allowing you to grasp progress in real time

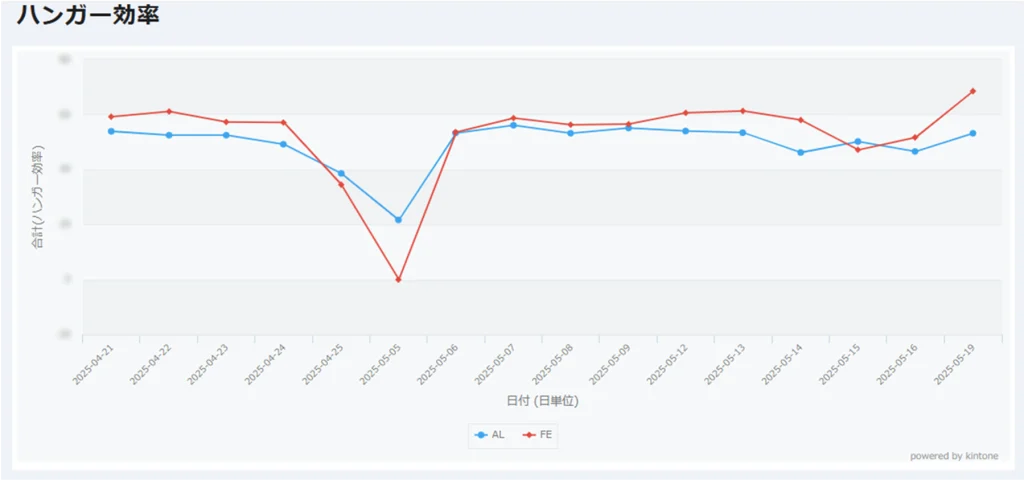

Efficiency indicators were not utilized and did not lead to improvement activities.

By visualizing KPIs in graphs, hanger efficiency and work efficiency improved immediately!

-

Management Department Mr. Mitsutoshi Migita

-

IT projects Mr. Yoshihisa Kitagawa

-

Manufacturing department Mr. Masanori Kobayashi

-

Mechanical Engineering Division I Mr. Yasunori Hashimoto

-

Machinery Division Akemi Udo

Real-time management of the 200-meter painting line at this very moment will change the workplace.

Kyushu Yanagawa Seiki Co., Ltd., located in Kikuchi City, Kumamoto Prefecture, is an automotive parts manufacturer founded in 1976.

The company will celebrate its 50th anniversary next year, leveraging its strength in its integrated system that handles everything from aluminum casting to painting and assembly in-house.

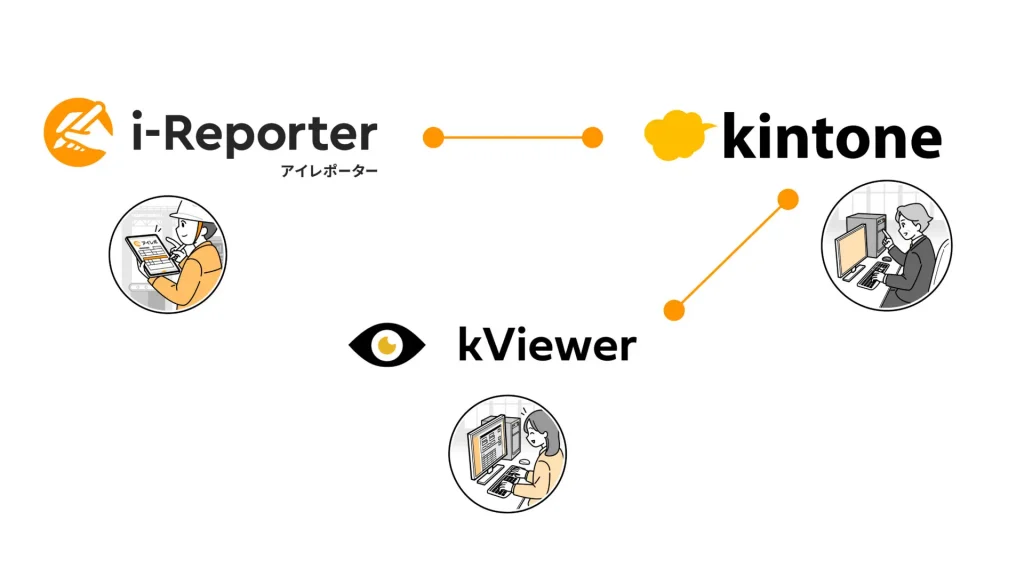

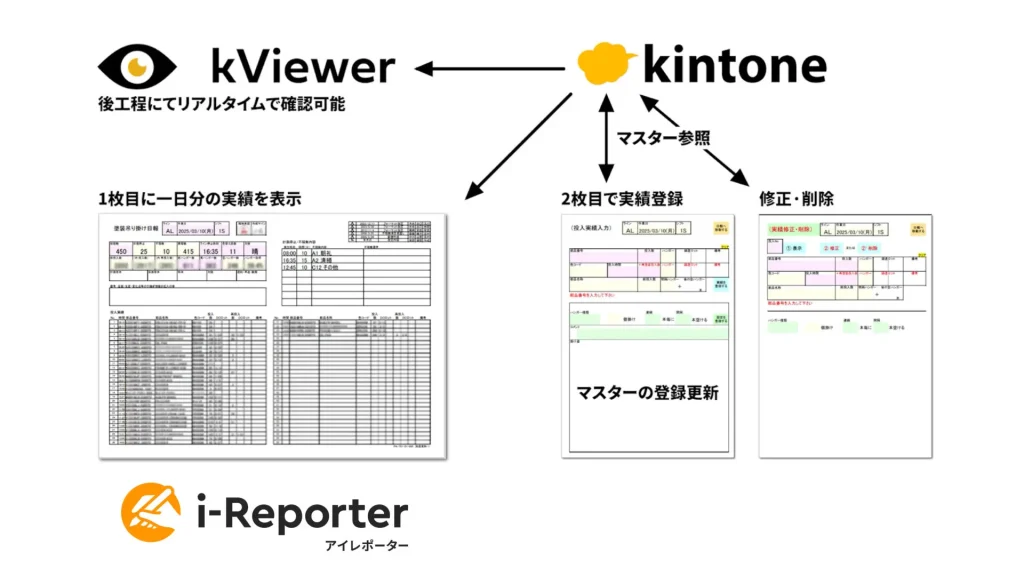

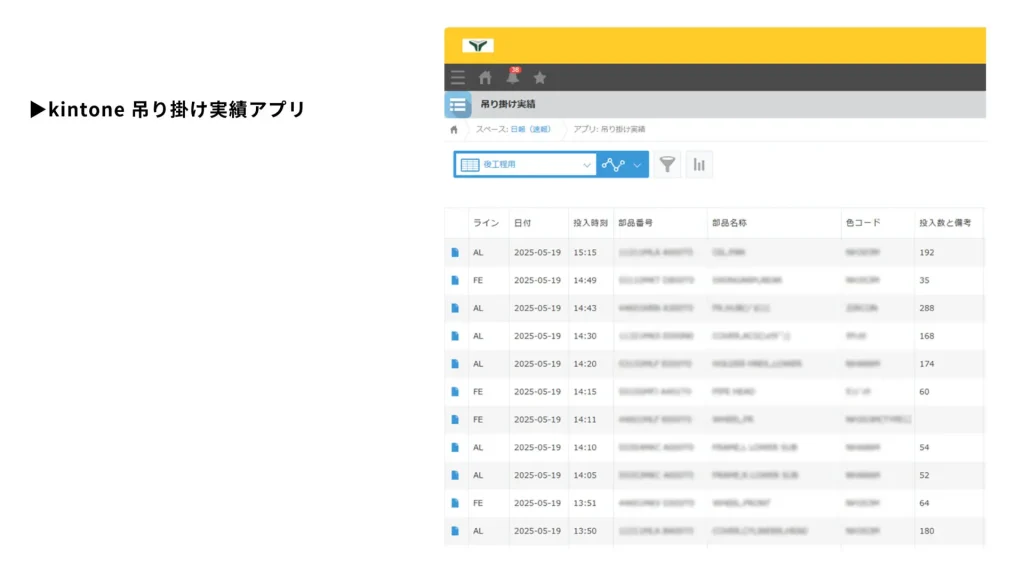

By introducing i-Reporter in 2021 and establishing a three-system integration with kintone and kViewer,

- Digitization of daily work reports: Approximately 190 lines of daily work reports are entered on iPads and information is shared in real time.

- Improved efficiency of change management boards: Change management boards for multiple departments can be viewed on one screen

- Real-time management of painting work: Immediately grasp the progress of the 200-meter long painting line

- Improved purchasing and supply operations: Eliminates the hassle of monthly calculations and enables real-time budget and inventory management

Achieved.

In particular, on the 200-meter-long paint hanging line, data can now be shared instantly for each task, creating an environment where managers, the next process, and the site can all understand the current situation. By visualizing hanger efficiency and work efficiency as KPIs, the improvement cycle has also accelerated dramatically.

*This article features an example of kaizen on a "painting hanging line."

Company Profile

Kyushu Yanagawa Seiki Co., Ltd. is an automotive parts manufacturer headquartered in Kikuchi City, Kumamoto Prefecture, and has been manufacturing important safety parts such as aluminum covers, components, functional parts and wheels since its founding in 1976. The company, which will celebrate its 50th anniversary next year, has the advantage of having a production system that allows it to handle all processes in-house, from aluminum casting to processing, painting and assembly.

The company has done business with many automakers and has been highly praised for its high quality and technical capabilities. When it was first established, it mainly produced motorcycle parts, but in recent years it has also focused on next-generation mobility such as hybrid vehicles and electrification, and is establishing a system that can meet new needs.

The weldable die-cast hollow frame, which was jointly developed with Honda Motor Co., Ltd. in 2002, is one of the company's signature products, and is a symbol of the company's technological capabilities, utilizing technology that is rare even on a global scale.

Integration of i-Reporter, kintone, and kViewer

In order to advance the digitalization of the factory, the company evaluated the cost-effectiveness of various tools, including electronic daily reports, BI tools, and IoT, and decided to introduce i-Reporter, which was expected to be the most effective, in 2021. Around the same time, the company also migrated from Notes, the groupware it had been using, to Garoon.

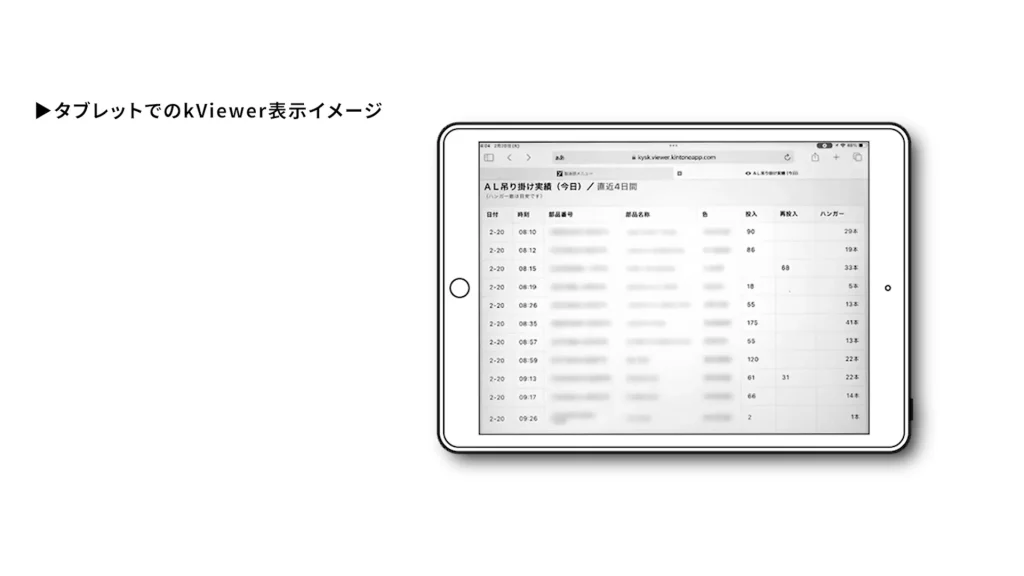

At the time, most people only viewed the kintone database, so instead of preparing a kintone for everyone, they introduced kViewer for viewing. i-Reporter was used to register approved daily reports in the kintone system, but there was a demand to be able to see the figures immediately, even if they were preliminary figures before approval. Therefore, the integration of the three products began when a system was built where automatically output CSV data could be linked to kintone every 15 minutes and viewed with kViewer.

Ingenuity to get tools used in the field

When field staff are asked to use multiple systems, they may become confused by having to view them in multiple places, so we have implemented the following measures.

Those who approve the daily work reports are required to use kintone and ConMas Manager, but the entry point for everyone else is Garoon, which has a portal screen that contains links to work records, operation rates, graphs, and more created with kViewer.

One clever idea is to use Garoon without using terms like kintone or kViewer. Also, by preparing a link that includes the report ID within the kintone performance data, users can immediately jump to the i-Reporter report.

Unique ways to use i-Reporter

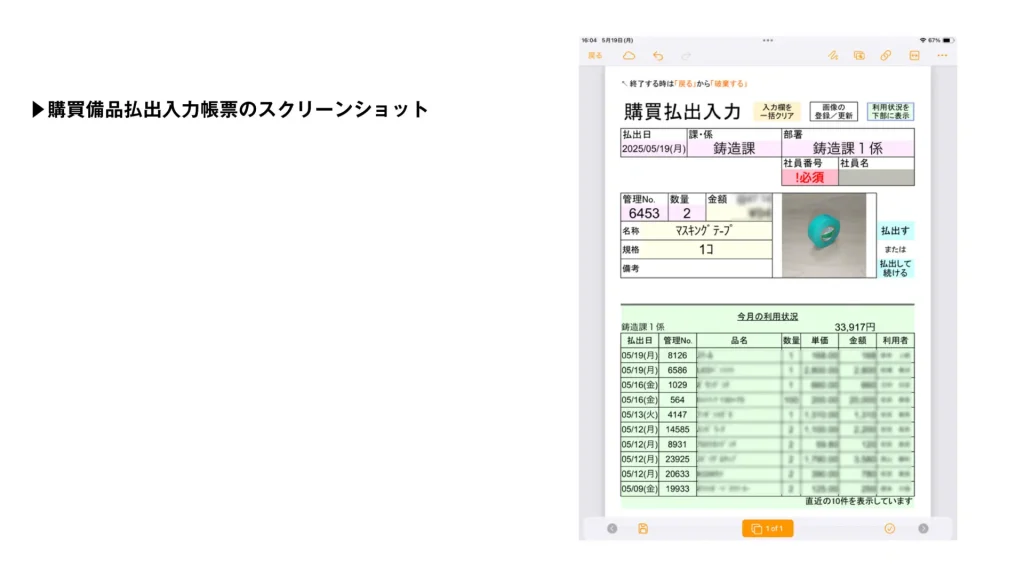

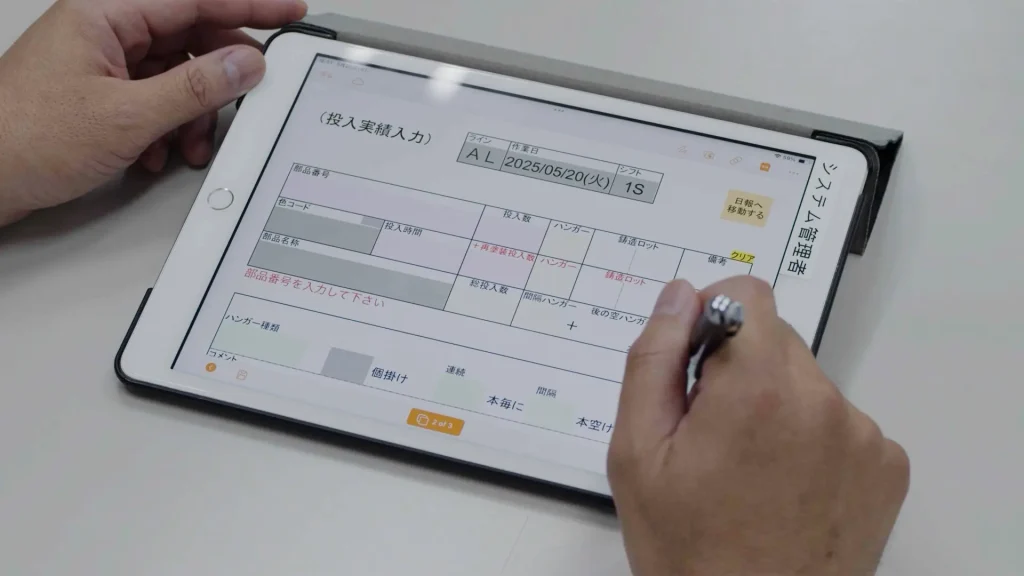

In addition to saving regular reports, i-Reporter is also used as an input interface for kintone. With i-Reporter, it is possible to adjust the resolution of images taken on-site and specify file names in advance, allowing for optimized use in business, such as saving to kintone.

For example, when looking at purchasing disbursement records, information such as the name, unit price, and image of the equipment is called up from kintone onto the i-Reporter report, and then the quantity and other information is entered and saved in kintone.

After that, by clearing it once, it will return to the specifications as a simple input interface, and the i-Reporter report itself will not be saved.

On-site improvement through "real-time visualization" of a 200-meter painting line

Utilizing KPIs also significantly improves work efficiency

Eliminates the hassle of paper daily reports and traveling to the site

Real-time input allows for immediate information sharing

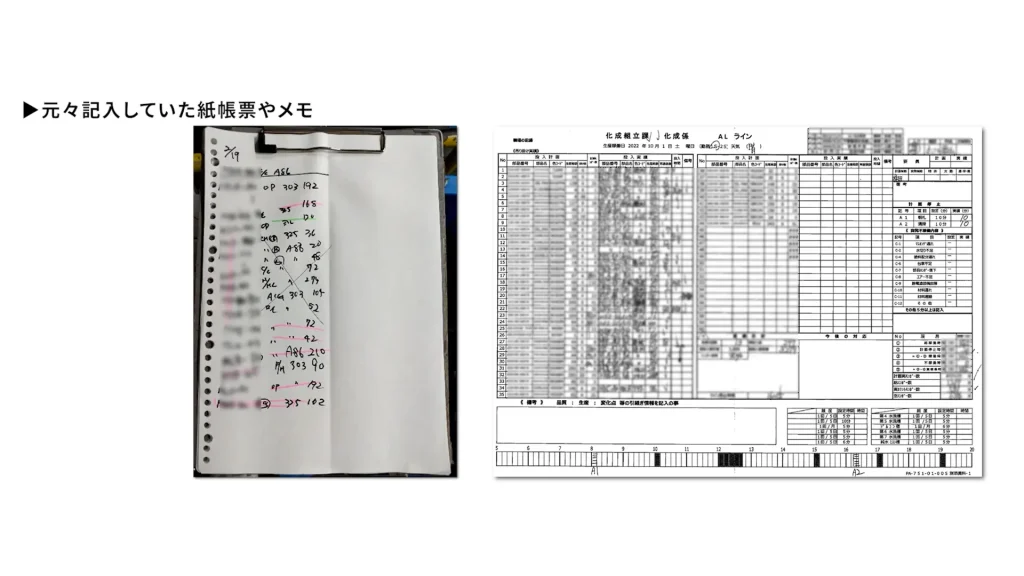

The hanging line, which is at the beginning of the painting line, previously used paper daily reports that were handwritten for each type of part. Those in charge of masking and inspection, which are processes that follow the conveyor, had to go to the beginning to check the hanging status, take notes, and then return. In addition, it took time for information such as hanger efficiency to be shared with managers, which meant that the information could not be fully utilized in improvement activities.

Kitagawa: "Previously, we used paper daily reports, and we recorded each task by hand every time it was completed. Since we work on dozens of different parts in a day, it took a lot of time to input the data, and it also took a lot of time to share the information."

He recalls that time.

Furthermore, the painting and hanging process is carried out on a line that is 200 meters long, with many parts being added one after another throughout the day. It was difficult for the on-site staff to know which parts were coming in at what time, which affected the preparation and setup for the next process.

Changes after implementation

After introducing i-Reporter, the daily reports for painting and hanging work were switched from compiling the entire day's work into a single form to inputting and registering each task in real time. As a result, the data is instantly linked to kintone as soon as the work is completed on-site, allowing managers and those in charge of the next process to instantly understand "which parts have progressed to what stage."

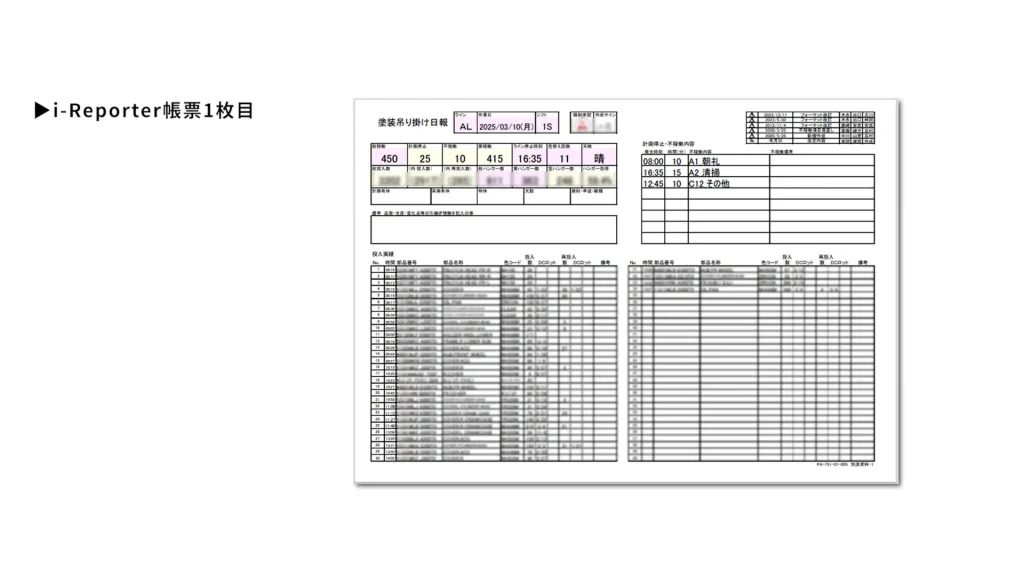

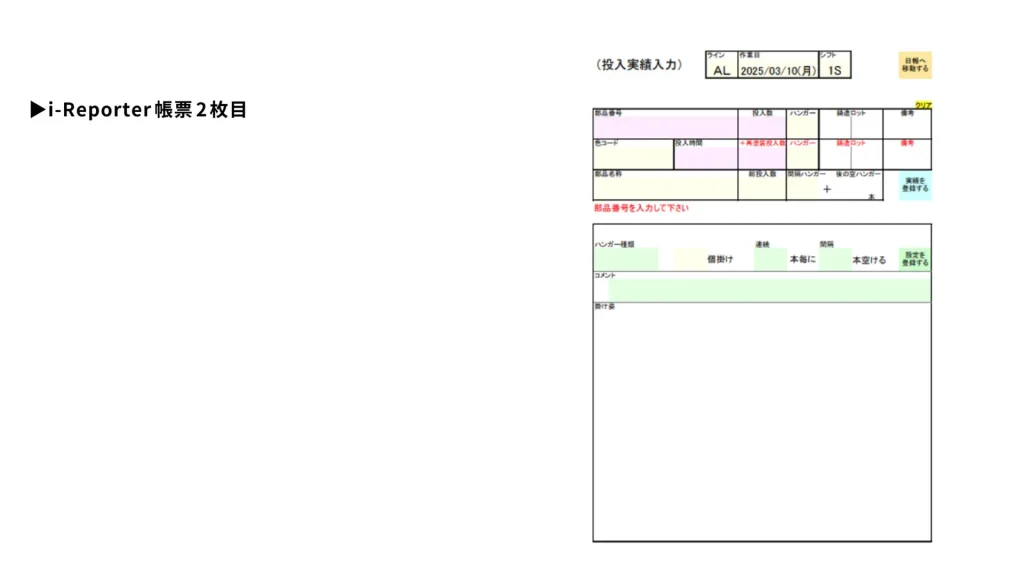

Input can now be made directly from a tablet or PC, and the report is now made up of three pages (1st page: overall summary, 2nd page: input for each part, 3rd page: screen for corrections).

The first page of the report is a summary, and like traditional paper daily reports, it has a layout that allows you to grasp the details of one day. The information entered into i-Reporter includes the date, line name, person in charge, and start and end time of the work, and the work results at the bottom of the report are obtained from kintone.

The second page is where you enter details for each part. After selecting a part from the master, the time, quantity, and other information are written to kintone as a single record, and at the same time, the actual results for that day are retrieved from kintone and displayed on the first page.

The third page is a correction screen, which allows for immediate corrections on-site if there are any input errors or additional information.

Kitagawa: "We can simply select information about parts and hangers from the master, which has reduced input errors."

Kintone's component master includes hanger types, photos of how the hanger looks when hung, and comments, and some of these can be freely registered and edited on-site.

Kitagawa: "We thought it would be useful to have information such as photos and comments to supplement the work manual. We hope that this will be useful for new employees in the future."

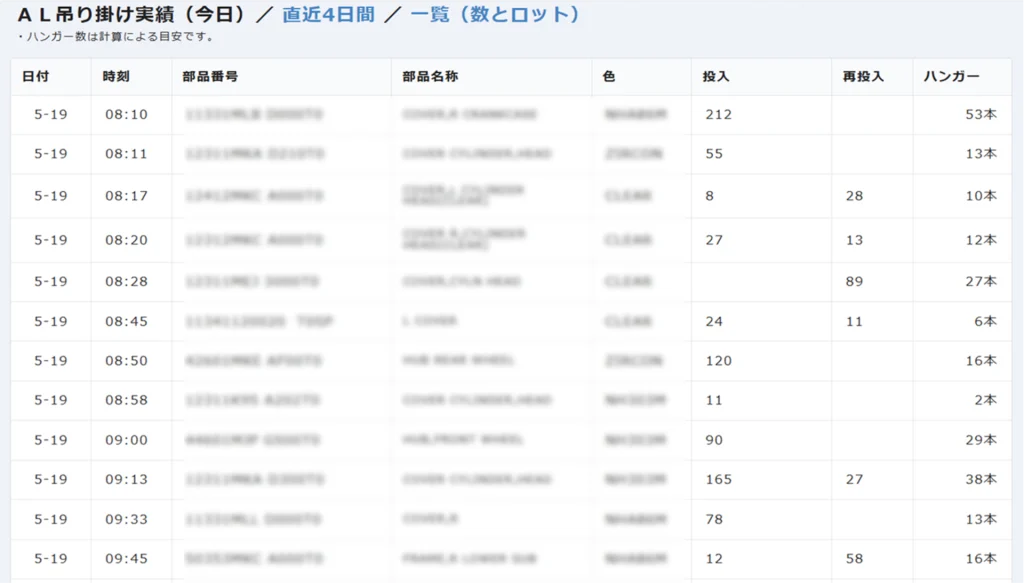

The entered results are linked to kintone one by one, allowing managers and on-site staff to grasp the situation in real time.

Instant data sharing for each task

The site, manager, and next process can understand the current situation

Additionally, kViewer allows for immediate graphing and visualization of KPIs such as hanger efficiency, accelerating the improvement cycle for managers. The kViewer results for hanging operations can be viewed by downstream process staff on their iPads, reducing the time required for work preparation and setup.

Kitagawa: "Previously, we didn't know which part would arrive next, so we had to go to the site to check it out, but now we can see the list at a glance with kViewer. It made me really happy when the person in charge was pleased after we made the improvements."

Specific effects before and after

- The time and effort required to travel to the site to check daily reports and take notes has been significantly reduced

- Necessary information can now be checked immediately on a PC or iPad.

- Hanger efficiency is graphed as a KPI and directly linked to on-site improvements.

- A downstream process manager said, "Previously, I had to go all the way to the hanging line to check on the next part coming in, but now with kViewer I can check the necessary information right at my fingertips, which has made work preparations smoother."

- Based on work performance and KPI data, on-site setups and work procedures are being reviewed, leading to improved productivity across the entire site.

Share information with anyone, anywhere with kViewer

A system that combines cost reduction and security

Visualization can be built inexpensively, and kViewer can make information available to users who do not have a kintone account, leading to cost reductions. Access can also be restricted from company PCs and iPads, and the fact that it achieves simple visualization has been highly praised.

Kitagawa: "With kViewer, even people who don't have a kintone account can view information, so we can share information with everyone while keeping costs down. We can also restrict access from on-site PCs and iPads, so it's safe from a security standpoint."

Kyushu Yanagawa Seiki Co., Ltd. has achieved improved work efficiency and on-site capabilities by accurately identifying on-site issues and flexibly utilizing digital tools.

Further improvements and developments are expected in the future.

Company Profile

Kyushu Yanagawa Seiki Co., Ltd.

- Established:

- 1976

- Headquarters:

- 1106-1 Asahikawabe, Kikuchi City, Kumamoto Prefecture, 869-1205

- Business Description:

- Business content Transportation machinery and equipment manufacturing industry

Main products: Aluminum die-cast parts for motorcycles and automobiles

The above reviews are quoted from ITreview.(https://www.itreview.jp/products/i-reporter/reviews)

※ITreview is a real-name, company-verified review platform featuring authentic feedback from professionals on the front lines.