Customer Stories: ADVANTEST CORPORATION

ADVANTEST CORPORATION

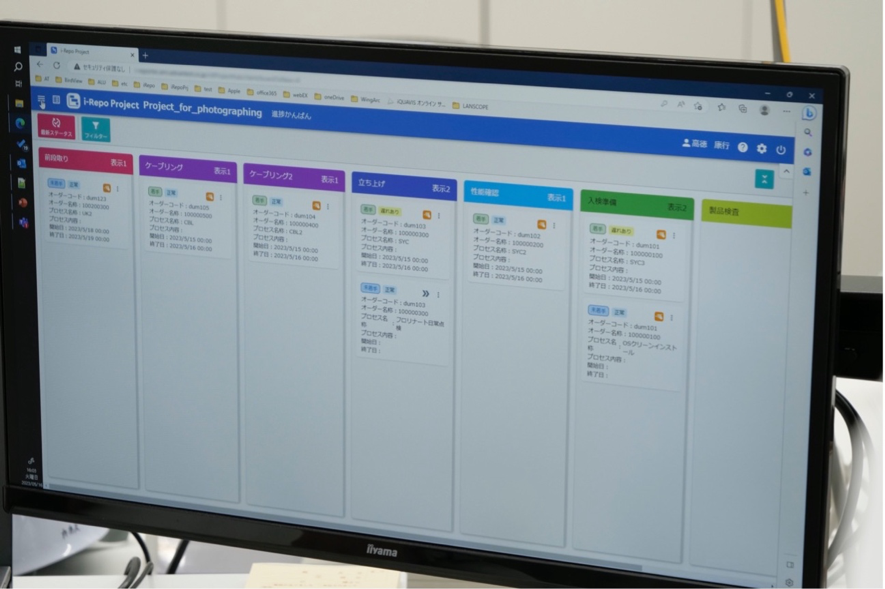

Integrate with the data in MES (Manufacturing Execution System) to check the work progress

ADVANTEST CORPORATION (hereafter, Advantest) is a manufacturer of equipment for a semiconductor test system, which is used to test semiconductors to see if they operate properly.

Advantest’s strength is its ability to provide the equipment necessary for the inspection of semiconductors on time to meet with the development of semiconductors, which has been rapidly growing along with the evolution of IT equipment.

Yu Nomura, Production Design Department, Department Manager

“In this generation, the usage of semiconductors has been expanding rapidly, as we live in a world where autonomous cars are being invented. So it is important for us to provide the products on time to these manufacturers.”

In the semiconductor industry, the percentage of manufactured products that meet quality standards (yield rate) is an important indicator for manufacturers regarding costs. Advantest provides quality equipment that can help manufacturers create test semiconductors, so they are considered an important partner for their customers.

To visualize the work progress

Yasuyuki Takatoku, Productivity Design Department

“To create one product, we use about ten forms.”

Previously, Advantest used paper to check the progress, but using only paper was inefficient. To solve this issue, they started using i-Reporter, which was the beginning of Advantest to become digital.

However, using i-Reporter to digitize the forms was not enough to check the overall situation.

“Even if we entered the results, the employees had to decide to see if the work was on track. So, we held a meeting every morning to get everyone together to check the forms and work progress.”

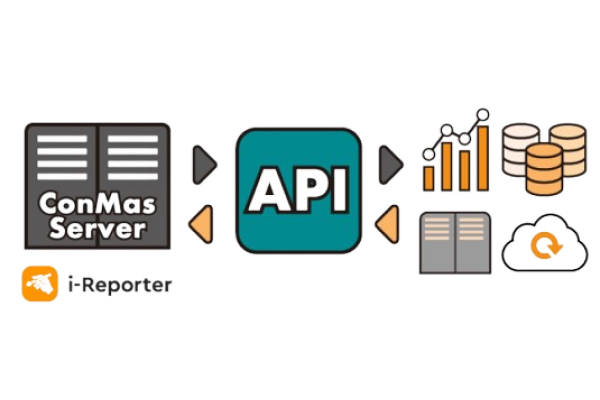

To visualize the work progress, Advantest needed to create a structure that can integrate the data in MES (Manufacturing Execution System) with i-Reporter forms.

With i-Repo Project, Advantest was able to achieve this.

Automatically retrieve the results entered in the form

Once they receive an order, the construction period and schedule will be entered in the MES. MES shows specific details of the project as they can see many tasks, and each has its own schedule.

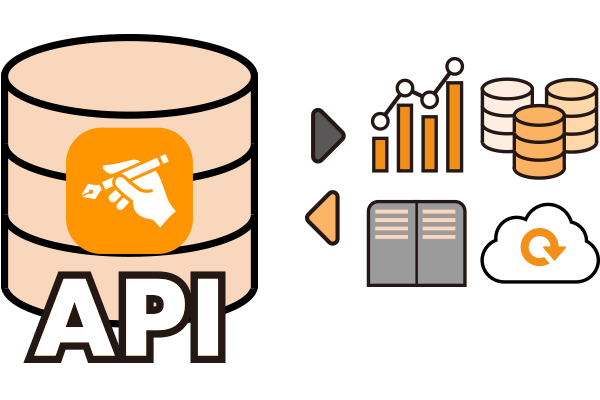

These kinds of data in MES can be transferred to i-Repo Project via WebAPI. When i-Repo Project receives the data, it will automatically create i-Reporter forms in accordance with the schedule.

At the manufacturing factory, employees use i-Reporter forms by tablets and enter the work results. Once entered, the started and completed tasks will also be sent to MES.

On MES, Advantest can check these details with the combination of their manufacturing plan that is already in the system, allowing them to keep track of the work progress.

In addition, i-Repo Project can visualize the progress of these achievements in real-time in the form of gantt charts or other charts, which also helped Advantest check the work progress easily.

To 0 working hours

Takatokuku-san feels that i-Repo Project has also helped reduce working hours, not just visualizing the work progress after becoming digital.

“Once we get an order, an i-Reporter form will be created with all the information we need. We are very impressed with the features of this tool. In the past, we’ve heard from our employees that it takes one hour a day to submit the i-Reporter form. Since the i-Reporter form can now be created automatically, those working hours have become 0.”

Also, their consigned factories (vendors) started to use i-Repo Project, which helped them check the work progress from other factories.

In the past, they needed to make calls or send emails to check the work progress, leading to some employees using their working hours just for this communication.

Now, these factories are using i-Repo Project, which allows them to check the progress in real-time. So, just opening i-Repo Project is now enough to check the overall situation of other factories, leading to fewer working hours and better work efficiency.

Also, i-Repo Project has helped them save paper, as they were able to save approximately 20,000 pieces of paper per year.

To create new value for their business

Mitsuteru Tajima, Functional Manager [Production IT Design]

While Advantest has managed to visualize the work progress, they are starting to collect a large amount of data related to the work results on a daily basis.

Tajima-san, Takatoku-san’s supervisor, says that Advantest’s next goal is to analyze this data and use the results to make further improvements, such as business process optimization.

Tajima-san explains, “With i-Repo Project and i-Reporter provided by CIMTOPS, we have finally made a basis to become digital and visualize tasks. We’d like to make the most of the collected data for the next step. The idea is to use and analyze the data effectively. Furthermore, we would like to keep using these services to think about creating new value for our business.”

Corporate Profile

ADVANTEST CORPORATION

Official websiteCompanies in various industries and sizes have deployed

i-Reporter in their businesses.

Ranked the number 1 paperless form solution in Japan by marketshare!

-

-

Use your existing paper forms or Excel forms as electronic forms on the go.

The best digital form solution for your business.