i-Reporter(アイレポーター) 業種別活用事例

Input of manufacturing results can be completed on-site

Target industries

- Manufacturing

- Because it is a paper form, there are errors and omissions, and there is variation in the accuracy and method of entry.

- There is a need to transfer data from paper to Excel spreadsheets or other systems.

- Long lead time from on-site work to reporting

- Equipment was visually inspected and the results and number of defects were transcribed onto paper, resulting in unnecessary work hours and transcription errors.

- Report creation is completed on-site, and the amount of post-processing work required to re-enter data into other systems or Excel in the office is greatly reduced.

- Immediate reporting and sharing with relevant parties. Significantly reduce lead time for countermeasures and analysis in the event of an abnormality.

- Standardization of report content and elimination of dependency on individuals

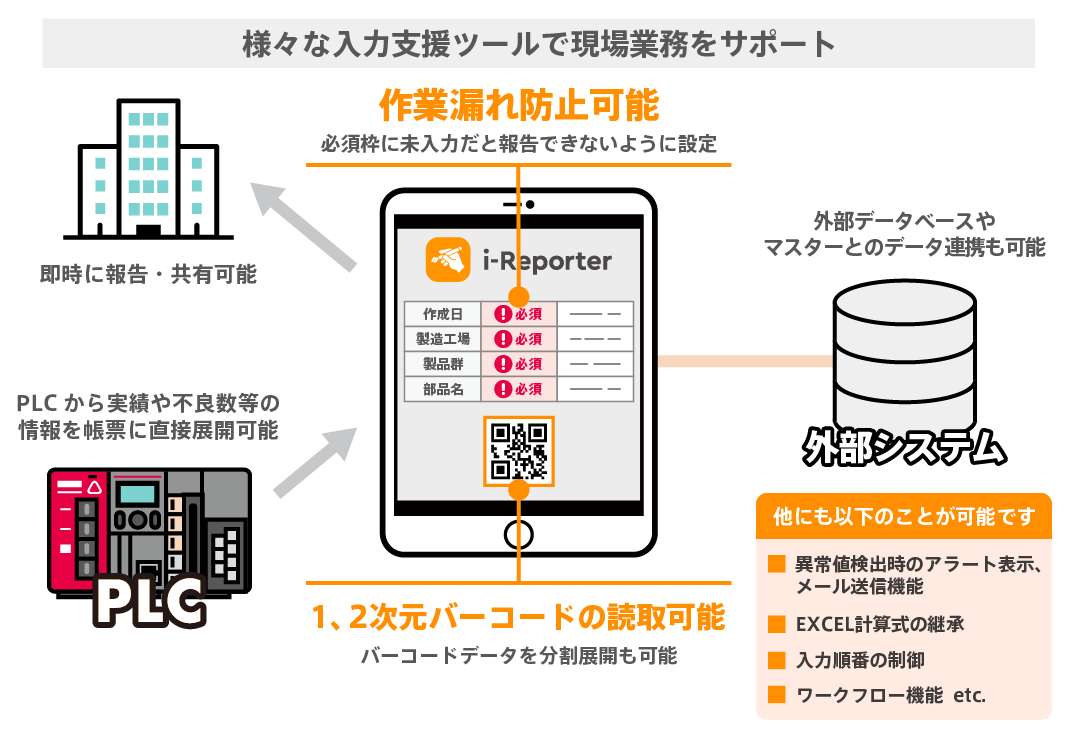

System Image

Example of created report

- Daily Report

i-Reporter functions to be used

- #Required Mandatory input Check An alert can be displayed if any fields have not been filled in when saving. Mandatory input fields can also be displayed in red on the form in advance. This helps prevent omissions in tasks or records.

- #Barcode cluster The terminal camera can read barcodes and record the contents on a form. It is also possible to set the decomposition even if one barcode contains multiple data.

- #Network Settings By linking input items, it is possible to control the input order and set parent-child relationships for input values. Even workers who are not familiar with input can input data efficiently and without depending on the individual, reducing omissions and mistakes.

- #Email notification Emails are sent to relevant parties according to various conditions such as document approval requests, saves, input values, etc. Multiple customizable templates can be created for notification emails.

- #External system integration It is possible to integrate with external systems using various methods such as CSV, API, database reference, etc. It is also possible to integrate with external scripts, PLCs, and sensors.